Custom Fat Spoke Motorcycle Wheels – Ride Wright Wheels

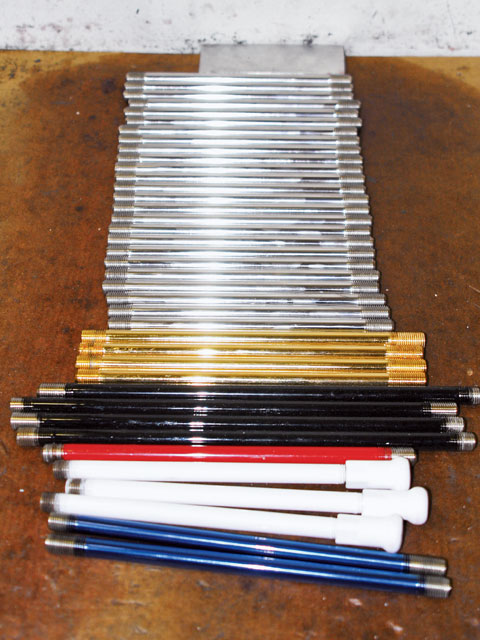

Ride Wright’s rainbow assortment of spoked wheel options is like a candy shop for motorcycle nuts.

Ride Wright’s traditional cross-lace and Fat Daddy radial-lace wheels start out with raw spun-steel rims.

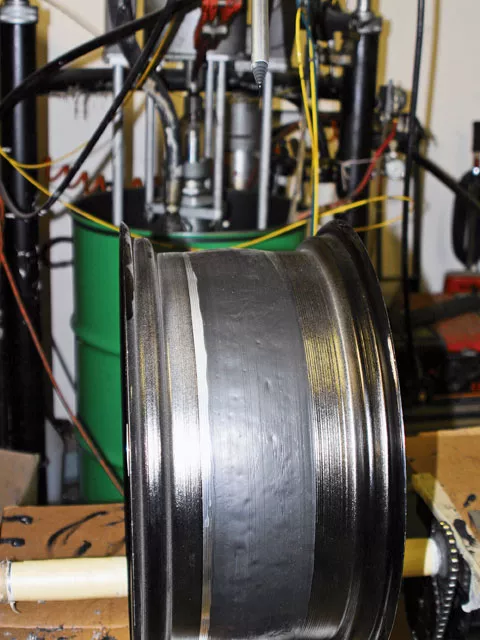

For the Fat Daddy wheels, the next step is dimpling. The rim is placed in a dimpling machine, which rotates the rim as it dimples.

After being dimpled, the rim is placed in the piercing machine. The rim is set on the machine at an angle, and the dimples are pierced at that same angle.

Here you can see the staggered pattern of the dimples and the angle at which they are pierced.

Once the wheels have been pierced, the rims are sent out for polish, chrome, and/or powdercoat, depending on what the customer wants.

A traditional spoked wheel gets its strength from the spokes being cross-laced across each other. However, with Ride Wright’s Fat Daddy wheel design, the hub end of the spokes is threaded so they can screw directly into the hub.

Before the Fat Daddy spokes are threaded into the hub, the threads at the hub end are hit with red thread locker, and the threads at the rim end get a touch of grease.

All of Ride Wright’s hubs are machined out of billet aluminum. The hubs for the Fat Daddy wheels are drilled and tapped to match the angles of the holes at which the rim was pierced. When it comes to lacing, first a couple of spokes are threaded into the hub…

…and the rim is placed over the spokes. Then the nipples are loosely threaded on.

This is a box of chrome nipples, but if you want red, white, and blue, Ride Wright can do it.

Once the 25 spokes are threaded into one side of the hub, the wheel is flipped, and the other 25 spokes are added.

After all the spokes are laced, it’s time to true the rim. When it comes to truing, Sam doesn’t let a wheel leave his facility with any more than 0.005 runout.

As the wheel is trued, the nipples are tightened and loosened until the entire wheel is within 0.005 inch.

One cool thing Sam can do with his wheels is seal them up so you can run a tubeless setup with spoked wheels. For tubeless, Ride Wright uses this silicone machine.

For tubed applications, a rim-band strap is wrapped around the inside of the rim to help protect the tube from the nipples.

When all is said and done, the layout of the spokes creates a pyramid shape when you look at the spokes from the rim to the hub. What this means is that as the wheel spins there will always be three spokes pointed at a 90-degree angle to the ground, absorbing the majority of the impact and dispersing the energy across the three spokes.

We liked these wheels so much we decided to pick some up for our Springer project.

Spoked wheels have come a long way since they were first made out of wood for use on carts, chariots, horse-drawn carriages/buggies, bicycles, and early automobiles. When it was first invented, the sole purpose of the spoked wheel was to make vehicles lighter and swifter, thus making it easier to transport objects and/or people from one place to another. While it’s impossible to re-invent the wheel, innovation and advances in technology have enabled the creation of spoked wheels that are not only much stronger and more reliable, but aesthetically pleasing as well.

If there’s one thing Harley-Davidson enthusiasts can agree on, it’s that spoked wheels look good on just about any bike. One person who definitely likes the look of spoked wheels is Sam Wakim, the owner of Ride Wright Wheels in Anaheim, CA. Sam has been in the wheel business for more than 10 years, and while he likes the gleam of a traditional spoked, chromed wheel just as much as the next guy, in his world of wheels, Sam wonders, “Why limit yourself to just one color or style when there’s a whole rainbow of colors and several styles to choose from?”

Ride Wright’s selection varies from the standard cross-laced 40-, 60-, 80-, and 120-spoke wheels with 3/16-inch-diameter solid stainless-steel spokes in traditional round, twisted, or diamond-cut spokes. Rim sizes vary from 16 to 21 inches in diameter and come in various widths, all the way up to 14 inches for 360mm tires. When it comes to colors, the sky is the limit. Ride Wright offers its wheels in any powdercoat color combination you can think of, from red spokes, hub, and nipples to one white spoke with 59 black spokes, matched to a green hub and a rainbow of nipples.

For all those who feel bigger is better, one of the hottest wheels Ride Wright offers is its 50-spoke Fat Daddy wheel. The wheels are highlighted by solid stainless-steel 3/8-inch spokes. Aside from the fat spokes, the way the wheels are laced gets a lot of attention as well. The spokes run straight out from the hub to the rim in a radial-lace fashion, as opposed to the more traditional cross-lace pattern in which the spoke exits the hub at an angle crossing over several other spokes.

While cross-lacing makes for a very strong and dependable wheel, Sam’s Fat Daddy wheels were developed and dyno-tested to be just as tough and reliable. In fact, the wheels are so tough, they’ve stood up to the abuse of AHDRA drag racer Valerie Thompson hammering the throttle on her daily rider, a 107ci ’00 Fat Boy with 18-inch Fat Daddys. These wheels caught our attention, and since Sam’s shop is right in our backyard, we popped over to see how they’re built.