Making Motorcycle Spacers – Tech

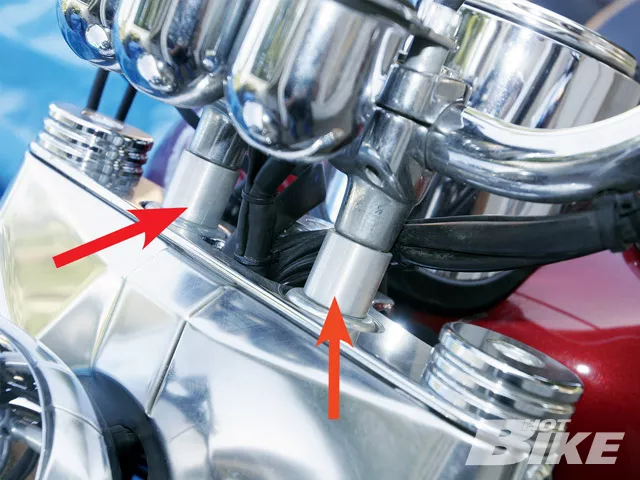

1. Last year we raised the handlebars on our ’06 Harley-Davidson Softail 1-inch by using spacers (arrows) made from aluminum bar stock. We cut the bar stock to a rough length and then finished them to final length and drilled a 1/2-inch hole through the length on our South Bend lathe.

2. For our 1995 Dyna Convertible we made a set of 1-inch spacers under the risers last year when we installed the bars. We were in the process of making some new changes to the bike and wanted to raise the bars an additional inch, so we crafted a new set of spacers 2 inches in length. Here we are showing the new 2-inch spacer in relation to the 1-inch spacer.

3. Here we have laid out on the bench top a spare set of risers (A), the 2-inch spacers (B), new, longer 1/2-inch diameter mounting bolts (C), washers (D) and nuts (E). There are two styles of risers: One style, the mounting bolts, slip through the top of the riser and are fastened with a nut on the bottom; the other style riser is threaded and the mounting bolt threads into the riser from below.

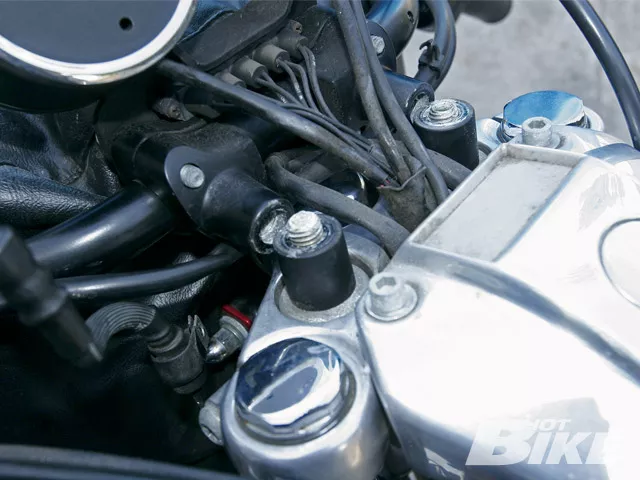

4. Our Dyna is equipped with the threaded style of risers. We loosened both riser bolts first, and then unscrewed them from the risers and laid the handlebar assembly carefully back on the gas tank, which we first covered with a fitted workshop cover to prevent scratches.

5. The mounting bolts slid out of the handlebar rubber bushings from below. We made sure to check the rubber bushings for cracking or dry rot. New rubber bushings were easily installed while the handlebars were off.

6. Here is the difference between the 1-inch spacer and the 2-inch spacer and the bolts. We like to use grade 8 bolts.

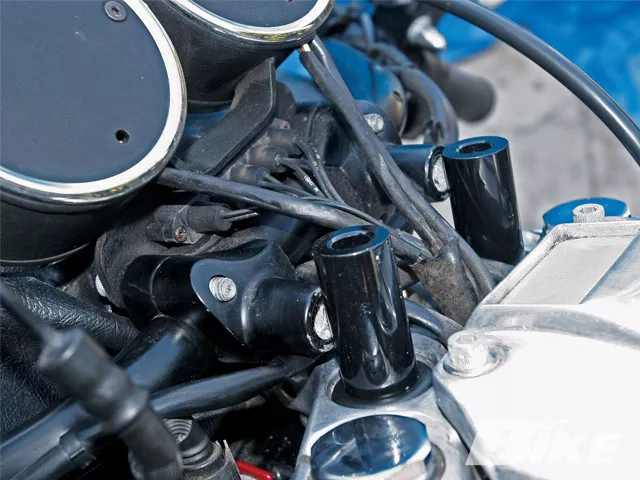

7. To assemble the new spacers, we first transferred the lock washer and bushing washer to the new riser bolt (also the handlebar ground wire if fitted to your model), applied a drop of Loctite to the threads, and inserted the bolt up through the bushings. We then slipped the new spacers over the bolts, making sure the top washers were in place on the handlebar bushings. We then carefully placed the handlebar assembly over the spacers and started each riser bolt a few threads into their respective risers.

8. We tightened the riser bolts, alternating from one to the other until tight. The factory service manual calls for a torque of 30-40 ft-lb. We also checked that the throttle and clutch cables were free and were not binding when the frontend was turned fully from side to side. Lastly, we re-adjusted the hand controls to our personal comfort.

One of the beautiful aspects of a stock or custom bike is the ability to fit the handlebars of your choice for looks and comfort. With that said and the daily increase in handlebar styles coming on the market, you would think there is a set of bars that are perfect for your application, and for 99 percent of riders, there is the perfect set of bars. But there are exceptions, and a couple of us here on staff fit into that short list of exceptions. Let’s face the facts: Until you ride your bike with a set of bars, you won’t be able to know for sure they are the ones for you.

We found a set of bars that had all the right contours and bends, but the one aspect that needed a slight tweak was the height. This modification is easy to accomplish by using a set of longer mounting bolts and spacers, placed under the handlebar risers. For normal Harley-Davidson risers, a piece of 1-inch-diameter aluminum bar stock (drilled through to a 1/2-inch diameter and cut to the needed length) accompanied by a set of 1/2-inch-diameter coarse-thread grade-8 bolts, 1 inch longer then the spacers is the easy cure for height adjustment. Half-inch coarse-thread riser bolts have been the norm, but be safe; take an old riser bolt to the store when you shop for new ones to insure you have the correct thread.