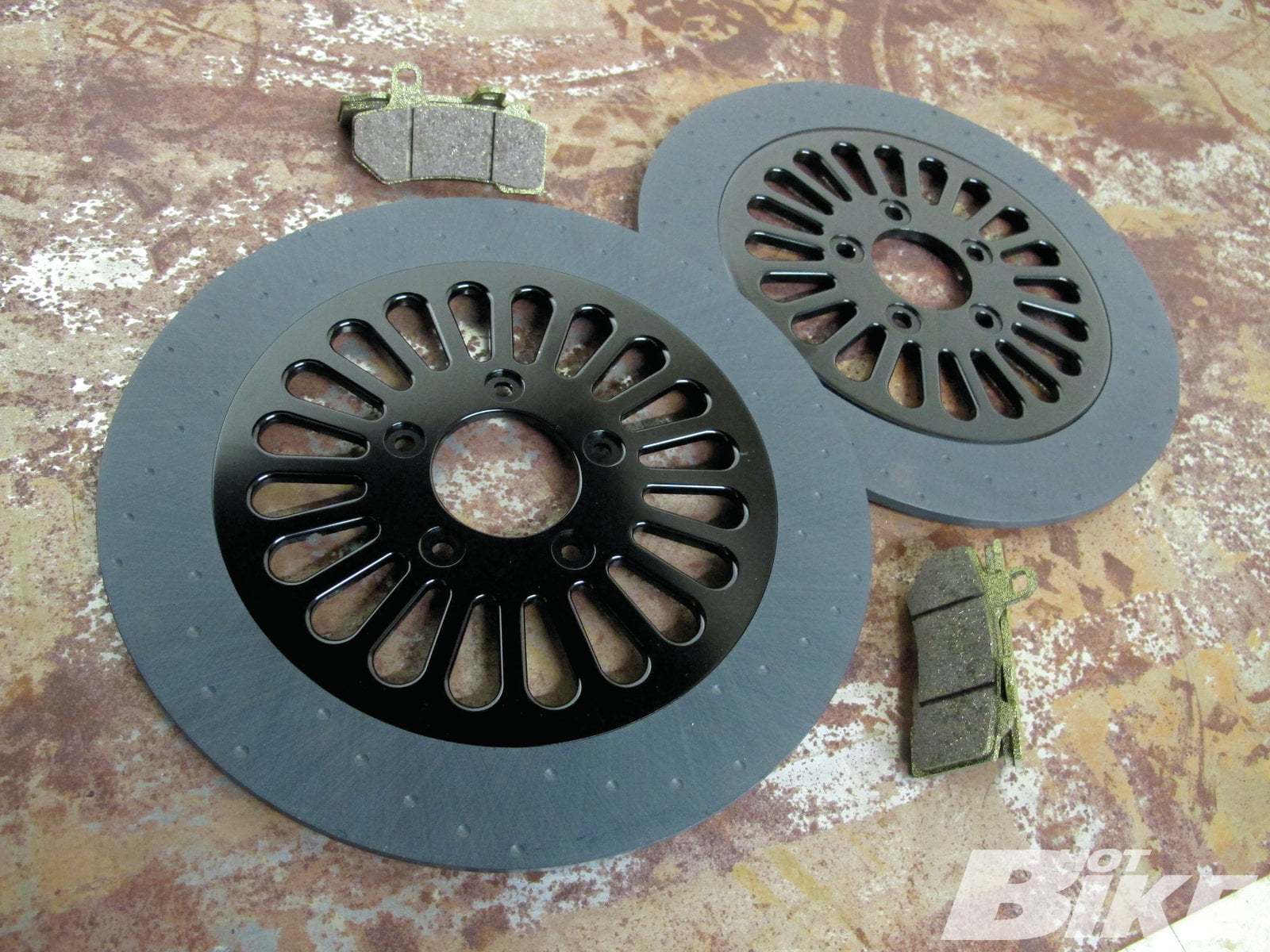

Metal Matrix Rotors | Lightweight Power Stoppers

Tech

On top of the structural makeup, the main benefit of metal matrix rotors is heat dissipation. Less heat means less friction, so when the binders are on, the lower heat generated from using a composite keeps brakes from fading substantially. To gain even more braking performance Lyndall brake pads use what is called transfer film technology. This means that the brake pads leave a film of friction material on the rotor’s braking surface. The benefit of this is that when the brakes are applied, the friction material is in effect rubbing against itself, providing a much more positive result over the two dissimilar materials used in a conventional braking setup. Other advantages of the Lyndall rotors are the big weight savings of up to 60 percent per stock rotor and since the Lyndall rotors and pads are nonferrous in their construction, they do not rust and virtually give off little to no brake dust as well.

Believe these brake components are too good to be true? Lyndall Brakes has many OE and custom applications available so you should try them for yourselves and find out just how good they are.