Picking Pistons Properly – Crowning Achievements

1. As much fun as it might be to grow big, it’s not without its pains. Although there is no substitute for inches, the closest thing to it is volumetric efficiency. Lots of both is virtually unbeatable! You won’t get power to match your inches if you don’t deal with details above the barrel.

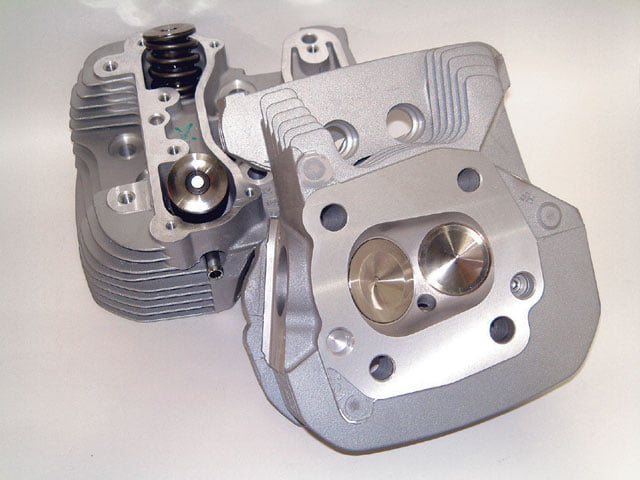

2. You can’t expect your heads to do all the thinking for you, either. Some, like this one, might be quite open…

3. …while others, such as this, are quite closed in comparison. It matters most if you mind…

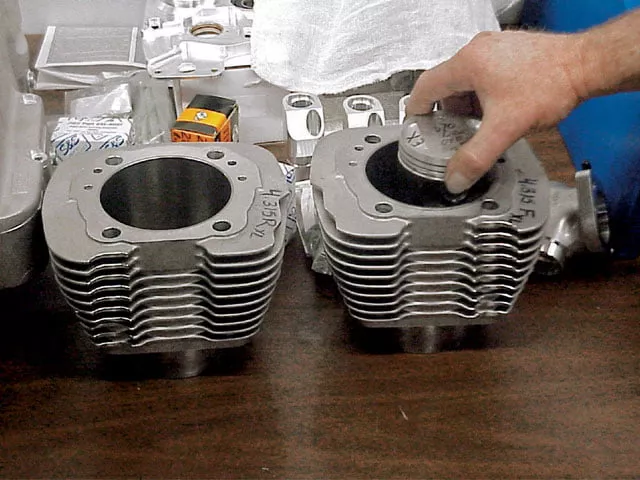

4. …keeping your pistons in shape. These days there seems to be a crown for every head, so don’t be shy about picking one that will perform most regally.

5. For those without a king’s ransom to spend, there remains the opportunity to improve your current lot in life. Sure, it’s work, but if you want to move from a dungeon into the chambers where power is really wielded, you must pay strict attention to teamwork-from floor to ceiling.

Let’s start with this much-there are three structures that create and affect what we glibly refer to as the combustion chamber. They are the cylinder head, the piston, and the valves. Any or all can be changed or modified to affect how much pressure is available from this chamber. (If time is money to us, pressure is power to an engine.)

So much for the ceiling, floor, and doors of our tidy little chamber (so to speak). Where it gets nuts is when you try to factor in any, erm, “wind” that happens to blow though those doors and all over the chamber-we hope! If there’s truth to the notion that if a butterfly sneezes on one side of the world it creates a hurricane on the other side, we’d better watch out for allergic insects and figure out how to batten down the hatches of compression. Usually the part that really “bugs” us is the camshaft, but that ain’t all there is to it, as we’ll soon see.

The cam variables that most affect compression are increases in duration and/or overlap. More of either means the chamber isn’t closed as long; therefore, more of that precious pressure can blow through without doing any good. So if you add much of these two elements in your hop-up, you’ll also need to increase what’s commonly referred to as nominal compression ratio. The time-honored way to do this has been to take some meat off the gasket surface of the heads in order to make more of the wind that blows through the doors (or should we say “valves”?). In other words, milled heads make a smaller chamber and thus more pressure.

Let’s save some time with this part of the concept, shall we? Stock mechanical compression on Sportsters (for instance) with standard cylinder heads is 9.0:1. Here’s how much you need to take off the surface to get to some common higher ratios (with factory flat-top pistons):

10.0:1 = .053 inch10.5:1 = .0672 inch11.0:1 = .095 inch11.5:1 = .114 inch

The formula for any old ratio (for any engine you might choose) is stroke x [(1/original CR-1)-(1/new CR-1)]. (Just don’t forget to factor in gasket crush.)

Here’s an example of a 1200 XL going from 9.0:1 to 10.25:1 compression.3.81* x [(1/9-1) – (1/10.25-1)]

3.81 x (.125-.108)

= .065 inch to mill

= .065 inch milled = 10.25:1 mechanical compression ratio

*(3.81 inches is standard for all X motors except the Firebolt 900s)

Think about it for a minute-the milling process, if you do nothing else, only makes the chamber volume smaller. So you’ve got pressure at the expense of volume. That means you won’t necessarily make more power. You’ll need to increase flow as well as pressure to compensate for the loss of volume. Often (besides the camshaft bit we discussed) that means bigger valves- the addition of which often puts volume back into the chamber, negating some of the advantages of milling in the first place. Most of the time milled heads work fine, which is why folks have done it all this time. But there’s another-maybe better-way to think about it.

A Short Discussion of VE (Which Is Not a Social Disease)The name of the game in engine building is (or should be) increasing volumetric efficiency (VE). Volumetric efficiency in a four-stroke engine is simply the relationship between the quantity of intake air and the piston displacement. In other words, VE = the ratio between the charge that actually enters the cylinder relative to the amount that could enter under ideal conditions. An engine would have 100-percent volumetric efficiency if, at atmospheric pressure and normal temperature, an amount of air exactly equal to piston displacement could be drawn into the cylinder. This state is practically impossible to achieve in naturally aspirated engines, (no supercharger or turbo) because the ports through which the air must flow offer resistance. (One notable exception is the XR750, some fine-tuned examples of which exceed 100-percent volumetric efficiency…but that’s a story for another day.)

Up, Down, and Flat OutTake the 883 as an example. It comes with flat-top pistons (floor space) and relatively small valves (doors). Yet simply by increasing the diameter of an equally flat piston, say to the size of a 1200 (a measly half-inch), you bump mechanical compression up too high (not enough space to stand up under a too-low ceiling). So to get chamber pressure back in the ballpark (say 10:1), most 1200 conversions these days employ dished pistons with concave bowls cut into the crowns. If ya can’t raise the ceiling, ya gotta lower the floor, as it were.

Stock 1200 XLs also use flat-top pistons, but with an open chamber head (high, domed ceiling) designed to arrive at a mechanical compression ratio of 9.0:1. (The VE may only be 65-75 percent, though.)

Buell 1200s from the late ’90s, with less volume in their “squish band” chamber shape than a stock XL1200 head, still manage an increase to a 10:1 ratio yet stick with flat-top pistons. Doing it this way, it’s a dead certainty that the VE on a 10:1 Buell is better than a 10:1 Sporty, all else being equal-sometimes to the tune of 80 percent or more. You begin to see where this is going?

The Buell Thunderstorm engine got bigger valves and a 10-percent larger squish chamber, which meant using pistons with a slight pop-up crown to get compression back up to an advertised 10.0:1. (The same ratio as lesser Buell engines of the era.) Make no mistake, the VE of this combination is superior to any of the other factory configurations by a lot more than a mere “point” in mechanical compression would indicate. And we can treat the “wind generators” as a constant-since both these Buell layouts use the same cams as Sportsters, whether stock XL grinds (S2 and M2) or the SE/Lightning version (S1, S1W, S3, and X1). With this kind of setup, VE can climb to 90-percent-plus, yet most of the improvement comes from the piston and its crown shape-which is not only a major player in determining compression, it can be one of the deciding factors in increased VE as well. Bottom line: Pistons are at least as important to a successful engine build as any fancy heads, wild cam grinds, or compression increases. But what exactly is compression in the first place?

Nothin’ but the “True”The true compression ratio (CR) of any engine at a specific rpm and throttle opening isn’t mechanical. It is dynamic. You can even calculate dynamic CR via this equation:

Dynamic CR = static CR x VESo let’s say we have a static CR of 10:1, and because we have the cam timing, pipe setup, and intake pretty close to perfect for our intended hop-up, the VE is pushing 90 percent at 6,000 rpm. The dynamic CR of this particular engine would be D = 10 x .9, or 9:1 dynamic CR.

But a simpler way to measure this would be to take an actual reading, in pounds per square inch, of the engine in question. Commonly called a compression test, this reading (along with its partner, the leakdown test) offers valuable indicators of the engine’s general health and helps determine where your engine’s at in terms of volumetric efficiency-i.e., power output. Most healthy street Harleys operate at an optimum cranking compression pressure of 170-175 pounds. Racing engines require higher readings of course, but much over 200 psi means there is an imminent meltdown in there somewhere and a much shorter fuse leading to a big blow-up for anything with a license plate.

Why is this important? Because it’s the state of tune we’re concerned with, and that’s not totally defined by either mechanical CR or VE. It’s the combination of the two. So what the hell does that mean?

Take It From the TopWhat’s most important for power and efficiency is finding how hot we get the ignitable mixture during compression. If the engine you’re tuning likes spark advance, does not live up to torque-output expectations, requires more fuel than you think necessary, and is detonation-prone, it’s time to examine your piston crowns. This may not be easy to get in a typical Harley engine (V-Rod excepted), but a uniform burn-residue color across the entire face of the piston crown is the bull’s-eye. Variations point to screwy air/fuel ratios that existed during the burning. Darker areas are fuel-rich burns, while lighter patterns mean air-rich mixtures. No color at all (unless the pistons are too new to have any residue buildup) usually indicates fuel wash, which can prevent complete combustion-which isn’t a happy thing for the rings, either.

Each (and all) of these symptoms indicate poor mixture quality, whether lean, rich, or a smattering of both. And you can see it all on the crown. Scrutinizing the tops of the pistons is also a quick method of determining whether you have different mixture properties between the two cylinders. Reading the piston tops is just another tool for seeing what your engine is trying to show you, which might turn out to be a need for different piston crown shapes.

Here’s the “Hot” TipAlthough it’s often a contributing factor, bumping compression ratio alone doesn’t necessarily lead to detonation. Poor mixture quality is more often the real enemy of efficiency, volumetric or otherwise. Homogenization of the incoming mixture prior to and during combustion is what will increase flame speed, hence volumetric efficiency, hence pony production. Let’s put it another way-it ain’t enough to just dump loads of combustibles into the chamber and squeeze. You gotta mix it up.

This mixture motion, or turbulence, is the frontier of study these days by some of the finest engine designers and builders in the business, and one major facet of mixture motion is the layout of (or modification to) piston crowns.

Tumble and SwirlYou get all this good turbulence and homogenization from so-called “swirl” and “tumble.” Motion along the plane of inlet flow generally describes swirl. It can be the same direction as mixture flow or run in the opposite direction. In other words, swirl can be positive or negative (which ain’t actually bad). Tumble works like a slinky headed downstairs-essentially an end-over-end flow perpendicular to the swirl. So while the mixture moves in jerks from the intake toward the exhaust, some of it tries to get out of the way, sideways.

The Crowning GloryA piston’s crown can affect both swirl and tumble. A flat-top piston influences swirl more than tumble, because there’s nothing but a flat, broad surface with a couple of small valve cut-outs to set off the swirl. But you can add tapered ramps and/or strategically placed texturing or dimples. All affect swirl, improve quench, and aid combustion efficiency.

Pop-ups or domes on the crown, carefully combined with the right shapes built into the cylinder heads, can shoot the flame front more toward the exhaust valve at the same time they increase compression ratio. Get too crazy with it, though, and all you’ll wind up with is a glorified roadblock to flame propagation and an inefficient burn (not to mention no power and all kinds of detonation from excessively lean spots in certain parts of the chamber). Excessive swirl can also cause fuel droplets to be flung out of the mixture, which screws up in-cylinder air/fuel ratios.

Like swirl, tumble can either aid combustion or reduce net VE and create torque losses. Together, they become the two sharp parts of a double-edged sword. As with everything else about engine building, it’s your job as a tuner to figure out which edge cuts it in your private chambers.