Top End Refresh: Part Three

The mule for this project was this ’96 Road King. The engine had more than 60,000 miles on the clock and was in need of an overhaul.

The mule for this project was this ’96 Road King. The engine had more than 60,000 miles on the clock and was in need of an overhaul.

Pictured are Branch-O’Keefe’s heads, Bennett’s honed cylinders, Andrews’ EV27 camshaft, +0.005-inch Harley pistons, JIMS adjustable pushrods, tappets (lifters), breather gear, and chrome head bolts. To seal everything up, a Cometic top-end gasket kit was used.

01. After the cylinders were honed, Eric sprayed the bores with WD-40 to prep them for the new pistons. Proper ring installation is crucial because the rings seal the cylinder. If they weren’t installed correctly, oil would go past the rings causing the engine to smoke. Eric installed the piston rings, and they were ready to be installed into the cylinders.

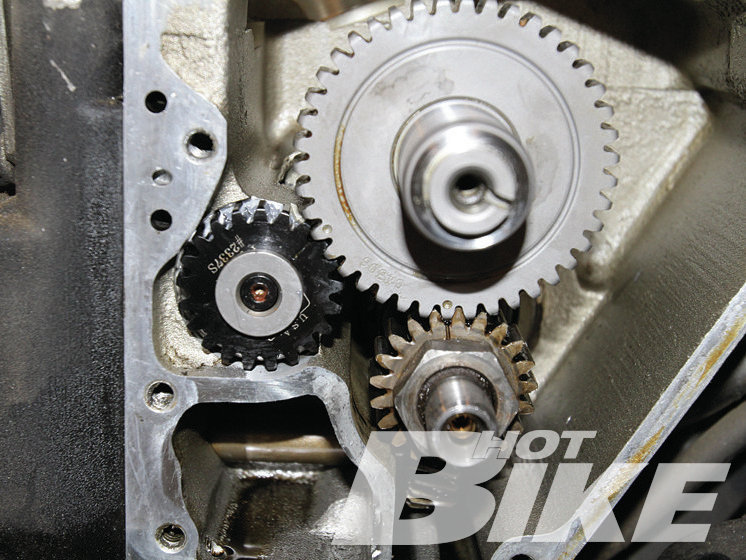

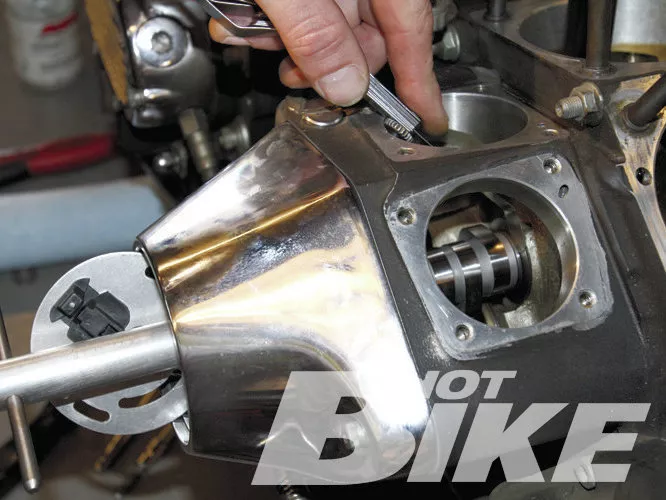

02. Eric removed the cam cover in order to remove the old plastic nylon breather gear, and the stock cam. Proper endplay for a breather gear is 0.010-0.012 inch. Eric installed the JIMS breather gear in place with an 0.110-inch shim and checked that the endplay was correct.

03. Eric then installed the Andrews EV27 camshaft. There are two timing marks on the camshaft gear that need to be lined up with the breather gear mark and pinion gear mark (arrows).

04. Eric dabbed some assembly lube on the outside of the camshaft gear and properly installed it with a special cam installation tool he made. JIMS also offers a cam tool that can be used for this installation. He then checked to see if the cam had 0.012 inch of endplay with a feeler gauge (arrow).

05. After Eric closed the camchest, he moved on to installing the JIMS lifters. He applied assembly lube to the lifters’ shafts and installed them into the lifter blocks with a magnet (arrow) that holds the lifters up so they don’t fall into the camchest cavity.

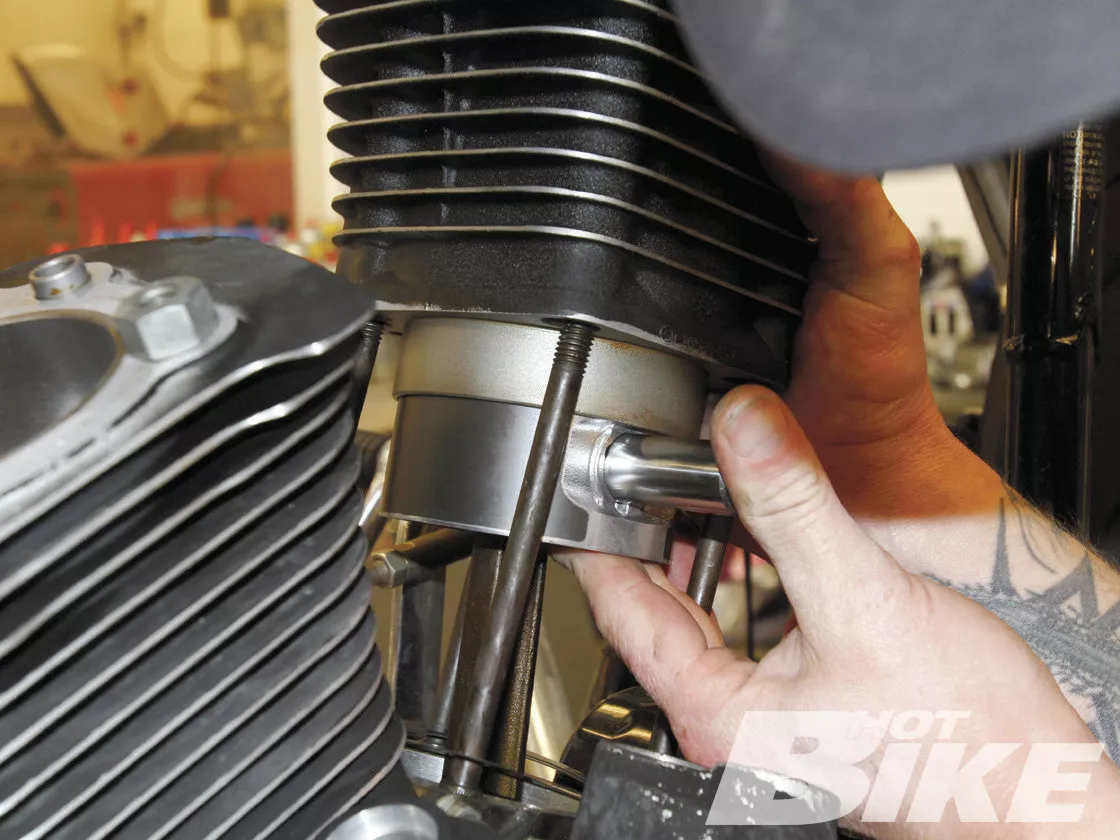

06. Once all four lifters were installed and torqued to spec, Eric slid the Cometic cylinder base gaskets over the cylinder studs. He then installed the cylinders one at a time while simultaneously installing the pistons to the piston rods with the wristpins and wristpin clips. Eric dabbed some assembly lube on the piston skirts for initial startup.

07. With the cylinders in place, Eric installed the Cometic Multi-Layered Steel (MLS) gaskets to the cylinders in order to install the Branch-O’Keefe Type #4 heads. He dabbed anti-seize on the new JIMS head bolts and torqued them to spec.

08. With the heads in place, Eric installed the Cometic intake manifold gaskets and re-installed the intake manifold.

09. Next up, Eric installed the Cometic rocker box gaskets and placed the rocker boxes atop the heads. He then placed Cometic O-rings in the lifter blocks and the heads in order to install the JIMS adjustable pushrods.

10. To install the JIMS pushrods, Eric slid them into their respective pushrod tubes starting with the intake pushrod. The JIMS pushrods are clearly marked with which receptacle to install them in (front intake, front exhaust, rear intake, rear exhaust).

11. Eric turned the engine over so that the rear intake valve was open. He did this to adjust the intake pushrod. He extended the pushrod all the way so there was no endplay, then he adjusted them 15 flats. (One flat equals one side of the nut. A hex nut has six flats.) When the rear intake/exhaust valve is open, you adjust the front intake/exhaust valve and vice versa.

12. Eric then extended each pushrod tube up to the rocker box and installed the clip making pushrod installation complete.

13. The rocker box covers were next to go on, but first, Eric had to install the rocker box cover gaskets. Once that was done he installed the rocker box covers and the top-end transformation was nearing completion.

14. The stock motor mount was reinstalled on the primary side of the bike.

15. Back to the pipe side of the bike, the Mikuni carb was reinstalled along with the air cleaner.

16. The tank was then tightened back down along with the dash.

17. To finish off the installation, Eric reinstalled the Samson headers and Freedom Performance Fishtail mufflers to the bike and tightened everything down in order to get the bike on the ground and off and running for some break-in miles.

In the last two installments of this three-part series we took you through the processes of how to properly refresh the top end of an Evolution motor and make some power while doing so. In this month’s installment we’ll recap the steps taken and give you the formula needed to achieve such performance gains.

In the first installment, we spent some time with Branch-O’Keefe in order to gain a better understanding of the company’s head porting and polishing process. Branch-O’Keefe’s process reshapes the heads’ combustion chamber to be smaller which increases compression and power. The exhaust and intake ports are re-ported and highly polished to flow air more freely and unobtrusively. After the heads were completed in part one, we delved into cylinder boring and honing with Bennett’s Performance in part two.

Eric Bennett, owner of Bennett’s Performance, is a V-Twin engine aficionado of sorts. In last month’s installment we only honed the cylinders since we didn’t need to remove that much material to fit the +0.005-inch Harley flat-top pistons. If we were to go +0.010 or larger, we’d need to bore and then hone. Since honing removes enough material while also creating the necessary crosshatch pattern to trap oil in its miniscule peaks and valleys located in the cylinder walls, that was the only route we needed to take.

In this installment we’ll piece back together the refurbished cylinders and heads and install a new Andrews EV27 camshaft ($187.01). The EV27 was chosen because when coupled with Branch-O’Keefe’s heads, it provides consistent power from start to finish, starting strong off the line with plenty of low-end torque, a smooth mid-range power delivery, and steady horsepower through the top end in the higher rpm range. Also used will be a set of JIMS Pro-Lite Worksavers adjustable pushrods ($228.20). The Worksavers save time with installation because they’re collapsible and can be installed after heads are torqued down. The heat-treated aluminum rods with heat-treated steel ends are lightweight and the front/rear intake and exhaust are properly marked for ease of installation. Also used will be JIMS Big Axle Hydraulic Tappets ($88.55 each), which eliminate the shock absorber action and are as close to a solid tappet as possible with the ability to compensate for heat expansion. These tappets will run in cast iron or aluminum tappet blocks. Because the stock breather valve gear is made of plastic nylon, it distorts and warps in the breather cavity, so we had JIMS send out its steel breather gear ($90.35). It’s sturdier and evacuates oil and crankcase pressure better than stock. To keep everything nice and tight, a Cometic top-end gasket kit ($102.10) will be used. Cometic Gaskets are top-notch quality and the company has been in business for more than 17 years, making a name for itself amongst all of the powersport and automotive industries alike. Cometic uses only the finest quality materials to ensure that your fluids stay where they’re meant to.

If you’re just joining us, check hotbikeweb.com for the first two installments of this three-part series. Once all the components were installed, we put some break-in miles on the Road King and put it to the test on the dyno. The bike’s owner was pleased with the results and it just goes to show that an old bike doesn’t have to stay that way. HB

Source:

Andrews Products

(847) 759-0190 | andrewsproducts.com

Bennett’s Performance

(562) 498-1819 | bennettsperformanceinc.com

Branch-O’Keefe

(562) 597-2850 | branchokeefe.com

Cometic

(800) 752-9850 | cometic.com

JIMS

(805) 482-6913 | jimsusa.com