Custom 2003 Harley Davidson Engine – Kryakyn Crusher Kit

When we arrived, the newly bored-out 95-inch cylinders with pistons were already installed.

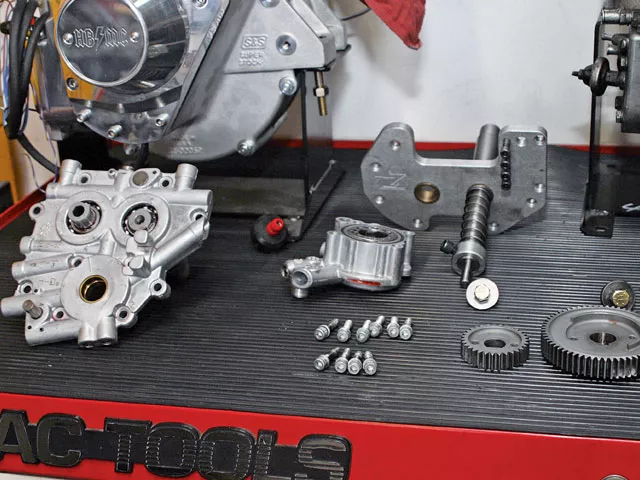

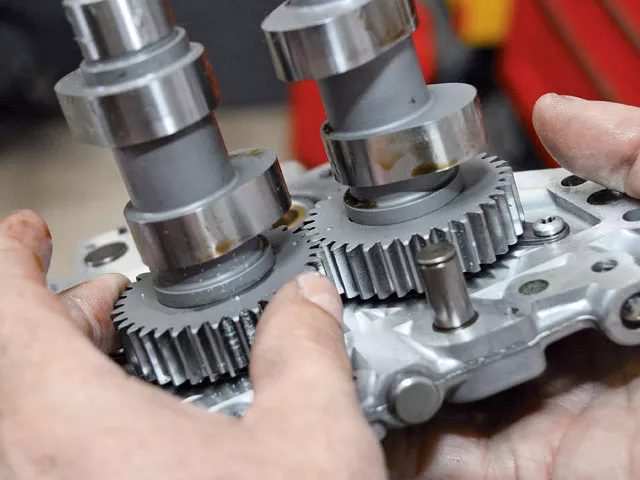

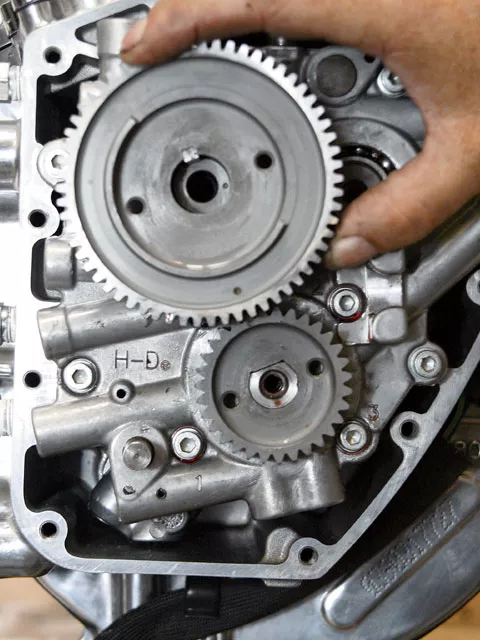

The cam plate, oil pump, and gear drives for the cams await installation.

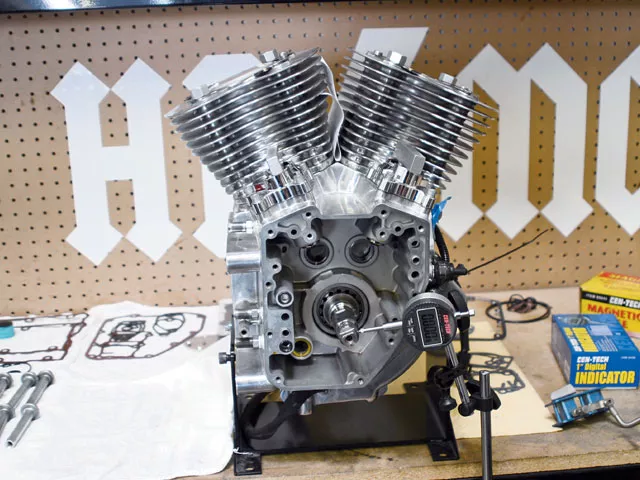

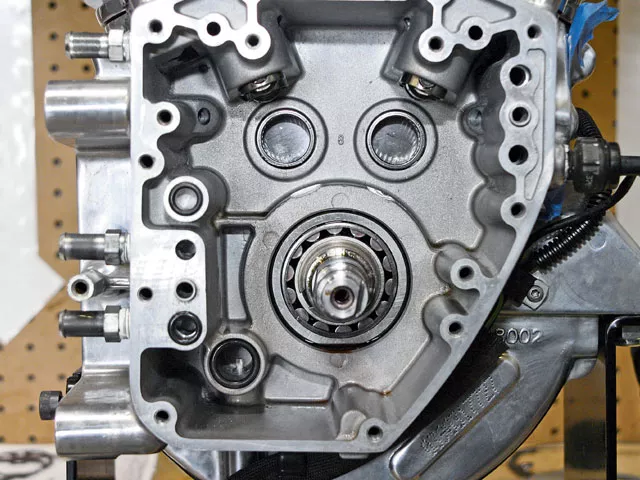

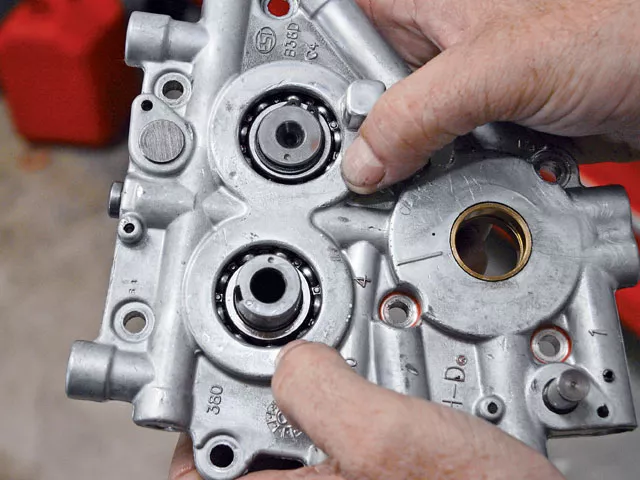

For peace of mind, new Torrington inner cam bearings were installed into the engine case.

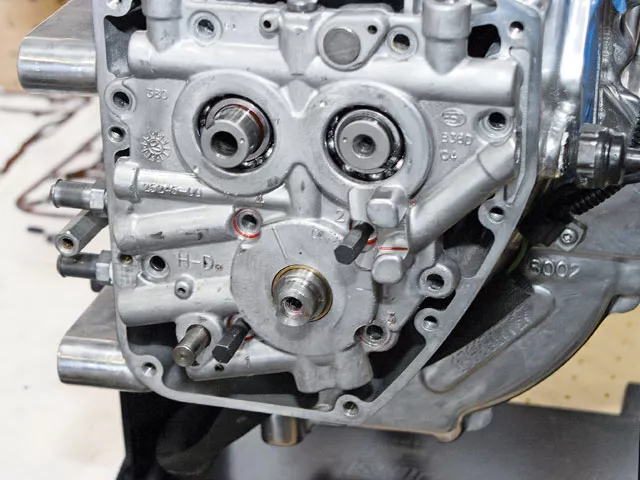

With the new camshafts installed in the cam plate, the timing marks on the backside of the cams are visible.

To make it easier to line up the cams, dots are placed on their outer surfaces as well.

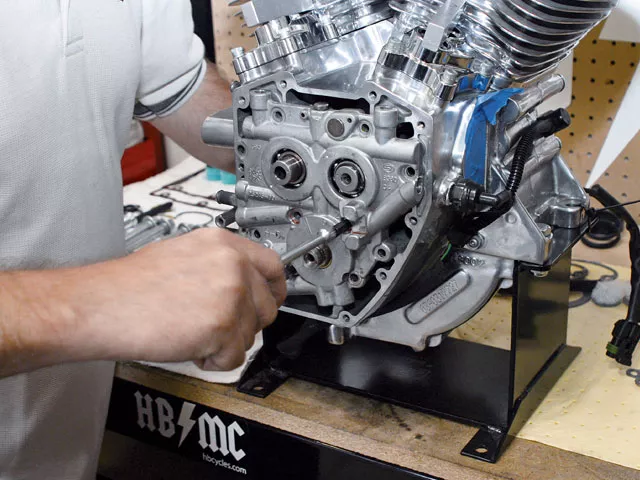

Dan loosely threaded the oil-pump alignment tools in the cam plate to properly align the oil pump while the lifters were held with a magnetic tool.

As the motor was turned over by hand, the alignment tools became loose as the oil pump centered itself. It’s a good idea to perform this step a few times until the tools stay tight; this means the oil pump is in the proper orientation and the remaining cam support-plate bolts can be tightened.

The S&S; gear drives were placed with the dots aligned with each other. These gear drives, with the design of the cams, eliminate the OEM chaindrive setup. The gear drives eliminate chain lash and lead to more precise control over valve timing with less drag.

Before installing the cam cover, we checked for any clearance issues between the new gear drives and the cam cover. Due to some interference, we used a rotary file to trim down the fins inside the cover…

…before tightening the cam cover bolts.

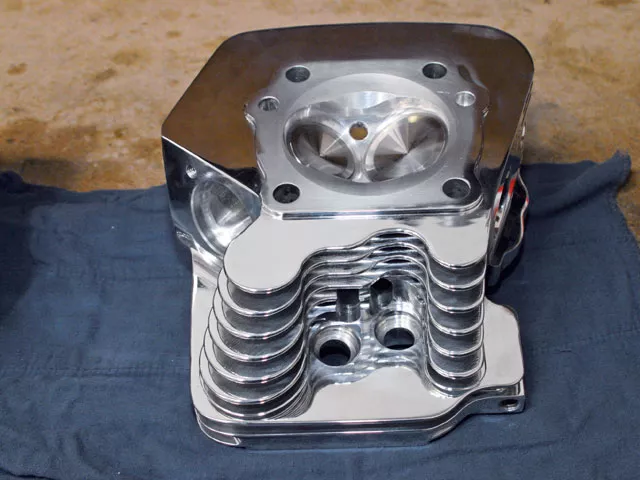

Looking at the working end of the billet cylinder head, we see the bathtub-shaped combustion chamber.

From the side the careful attention to port detail can be seen. They were designed to produce high-velocity flow, which provides better cylinder fill.

After putting the MLS gaskets on the top of the cylinders, the heads were installed and torqued in increments of 25, 35, and finally 45 lb-ft.

We would reuse the H-D rocker boxes and arms but there was some interference once we placed the rocker box over the valvesprings.

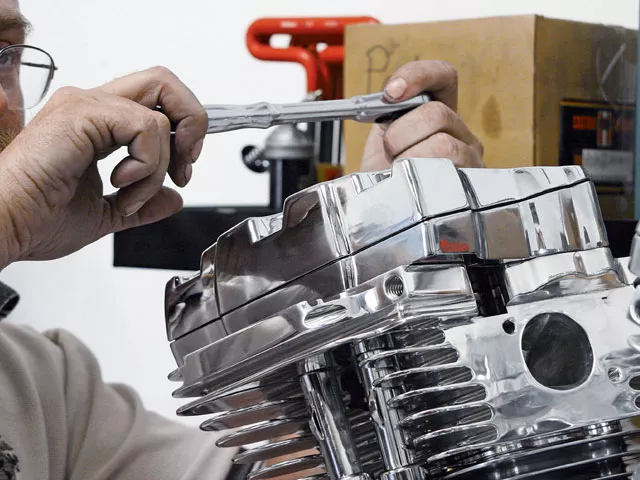

Therefore, we had to open up the holes in the rocker box before proceeding.

Then it was time to install the rocker-arm assemblies into the rocker box.

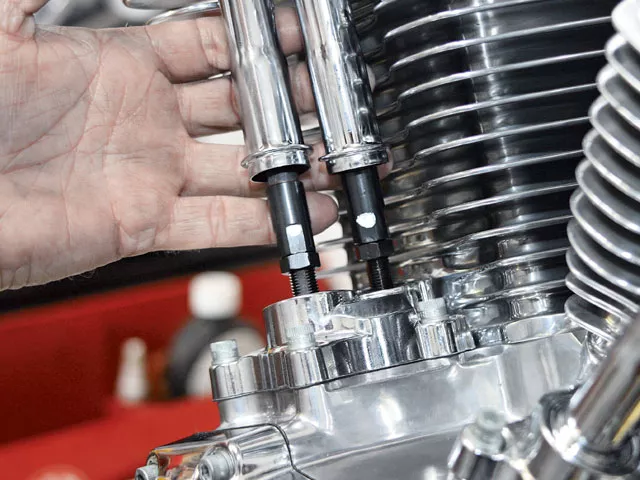

Adjustable pushrods were used. We slid them through the pushrod tubes and through the heads. Dan decided to marked them with white paint.

The pushrods were adjusted with two wrenches. It’s important to let the lifters bleed down to ensure proper adjustment before moving onto the other pushrods.

Once all four pushrods were adjusted, the top rocker box was installed.

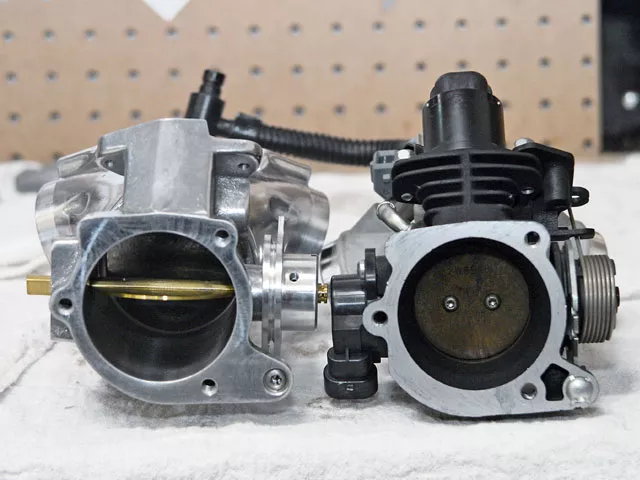

On the left is the new Kryakyn throttle body, with the OEM unit on the right. The Kryakyn unit is a high-volume unit that flows much more air than the stock throttle body.

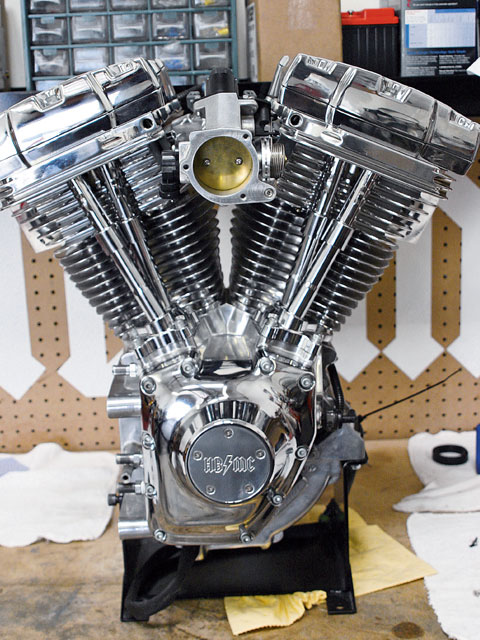

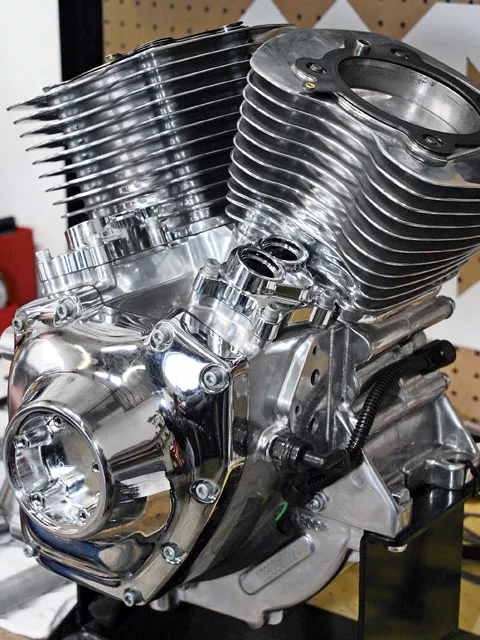

Now we just needed a chassis to throw the motor in so we could get in some break-in miles before putting the package to the ultimate test: the dynamometer.

Readers and riders alike have come to know the name Kryakyn for providing accessories and parts to the motorcycle industry. If you want to dress up your dull aluminum, add some style to your air cleaner, or just need some extra shine, it can all be found in the Kryakyn catalog. With the show side of things covered, Kryakyn has officially entered the “go” phase with the release of its high-performance line of go-fast motor parts for Evo and Twin Cam motors.

Entering the world of hi-po Harley motors is not for the faint of heart or the uninitiated, so Kryakyn decided to work with one of the best motor builders the H-D world has ever seen. Enter Mike Roland, a veritable encyclopedia of motor magic dating back four decades. He’s been responsible for and a part of world-record V-Twin performance efforts, from Top Fuel dragsters to land-speed records at Bonneville. He was the first human being to go 190 mph in the quarter-mile on a Harley and was responsible for the heads on Doug Vancil’s record-setting machine, as well as many other racers. All these years of experience have given Mike an understanding of how to make power in a Harley-style motor.

However, that experience has also gained him insight into how a bike used only on the track is a completely different animal from a street bike. For one thing, the place where power is concentrated is completely different. A race bike is tuned for maximum power at wide-open throttle, whereas most Harley-type bikes spend very little time near the redline-if at all. Many builders boast of high power output, but at revs that most people will never use. Mike wanted to build a package that produced big torque and horsepower numbers yet still keep the motor streetable and well-behaved. This means a broad powerband where the torque kicks in low and keeps on pulling for as long as you can hold on. Another concern with many high-performance motors is their ability to run smoothly on the lower grades of gasoline we have at our disposal. Many performance motors need beefed-up starters and/or compression releases; they tend to run hot, detonate (ping), and have a loud valvetrain. These are not factors that make for a good street bike. Mike wanted to tackle all of these issues when designing the Kryakyn Wild Things engine packages.

We heard Chucky Fryman at Huntington Beach Cycles was building a bike for Kryakyn that was going to feature the new Wild Things “Crusher” kit installed in an ’03 Harley-Davidson Twin Cam motor. Displacement was increased to 95 cubic inches with a set of 3.875-inch-bore CP/Kryakyn forged pistons designed in conjunction with longtime piston guru Snake Calvert. The forged 10.5:1-compression pistons, with deep valve pockets to accommodate high-lift cams, were designed with a special skirt shape that requires less break-in time while running quieter. At the heart of any serious motor, the cylinder heads were designed with the goal of making useful street power in conjunction with the other valvetrain components. Within the bathtub-shaped combustion chamber sit a 1.980-inch stainless intake valve and a 1.630-inch exhaust valve. Extensive work was done on the flowbench to come up with a port design that benefits both the incoming and exiting air/fuel/exhaust. Intake ports were raised 3/8 inch, thus providing increased airflow and, more importantly, velocity, while the constant-radius D-shaped exhaust ports provide the means for quickly removing the spent gas from the combustion chamber. To further enhance the functionality of the heads, extra cooling fins were added with larger breather passages and oil drains. Due to their design (in conjunction with camshaft timing), even with high static compression, no compression releases or a high-output starter are needed. The TC-46G cams eliminate the stock cam chain drive, instead utilizing S&S;’s gear-drive setup. These mild-ramp cams lower starting compression for easy starting while delivering high torque and hp throughout the powerband.

A bottleneck in many high-performance H-D motors can be the intake manifold and EFI throttle body, which restrict airflow. To ensure maximum intake charge, Kryakyn designed a larger 57mm straight-bore throttle body for all Delphi-equipped bikes (’01-present). All of the stock components and sensors, including OEM cruise control, bolt right up to the new throttle body without modification. It also uses the stock air-cleaner bolt pattern, so air-cleaner choices are numerous.

To keep the oil where it’s supposed to be inside the motor, Kryakyn went with Cometic gaskets to pair to its performance packages. Three-layer multi-layer steel (MLS) head gaskets, combined with Cometic’s cam, pushrod, and top-end gaskets, were used for their exceptional sealing abilities. Working with Cometic, Kryakyn engineered a new copper exhaust gasket that will not rob power by protruding into the exhaust flow the way mesh gaskets frequently do.

Follow along as Dan Rigby installs the parts. There were a few modifications to the OEM parts that needed to be done to get everything to mate up correctly. Kryakyn claims that this motor package would produce 120-plus hp with gobs of usable torque. We put them to the test. Results follow.

We took the custom bagger the motor was in and rode it over to Geoff Gaites’ Cycledoctor shop for dyno tuning. After dialing in the ignition and the EFI map, the 95-inch motor produced a whopping 120.72 hp with 108.07 lb-ft of torque. But those numbers don’t tell the whole story. The chart shows usable street power; at 3K rpm the motor pulled more than 90 lb-ft, rising to peak torque at 5K before a slight leveling-off. This motor has no problem pulling the bagger’s front wheel off the ground.