No Excuses

This Harley-Davidson FXR started out as an insurance buy-back through the shop that I rode around and immediately realized it held up to its reputation. It was only a matter of time before I threw a bunch of parts at it to make it even better. I blew the 107-inch Evo motor up in it a few weeks before on a trip back from Arizona, so I began the modifications to the frame from a different Twin Cam motor I had. The work required to get the motor and trans in was a bitch. I had to do a ton of little things in order to build a bulletproof drivetrain to get me quickly from California to Arizona and everywhere else, as we ride a lot and beat the shit out of our bikes.

<div class="st-block quote text-

Notice: Undefined index: st_text_align in C:laragonwwwhotbike-importblocksquote.php on line 1

“>

We were able to spend time on fitment of the motor and transmission before we even fired the bike. Having a huge motor that makes a ton of power is cool, but I think having the handling and stopping power in control is also a huge part. There was no huge rush to get the bike done and running because in the end it is my personal bike.

The 113-inch motor started with Screamin’ Eagle cases with JIMS bearing Timken conversion and a Screamin’ Eagle Forged Pro Stroker flywheel that was sent to Darkhorse for some work. Feuling Parts also helped out with a cam plate, race oil pump, race lifters, and pushrods with Screamin’ Eagle roller rocker arms. The cam used is Dave Mackie Engineering 630 gear driven cam that would go well with the 103+ heads with 11.1:1 compression that DME did some really nice porting and valve work with. To get the motor enough fuel, we used a polished 48mm Mikuni carburetor with a Top Gun manifold. The ignition was an easy choice for us. We wanted something that would be able to be easily adjustable and reliable, so we chose the Dynatek TC88 digital ignition. Custom Cycle electric also put together a high-output charging system for the FLH drivetrain. Once we had the motor assembled and in the bike, Monty Howard at Dave Mackie Engineering from Pro Cycle Dynamics was a huge help with the assembly and working way too late at night to get it fired.

Shortly after the motor was running, we began to get the suspension figured out. We decided to go with the inverted Öhlins front end, Speed Merchant trees, dual radial Brembos with Kraus Motor Co. mounts, Ferodo CP race pads, and 13-inch Lyndall Racing brake rotors. That alone was a huge increase in the handling of the bike. The rear shocks are Öhlins fully adjustable reservoir shocks 14-3/4 inches long. The rear swingarm was changed to a Metmachex Engineering arm that is twice as rigid and weighs half as much as the stock arm. We modified a Custom Cycle Engineering Spherical kit on the pivot to accept the larger transmission pivot on the Screamin’ Eagle six-speed FLH transmission and added the urethane pucks to keep the back end tight. We also added support to the base of the Baker +1 oil pan. The additional quart of oil also helps with cooling, as it takes longer for all the oil to pass through the motor. This was a good option instead of running an oil cooler.

Growing up on the racetrack with sportbikes, we wanted to integrate as much performance into this build as we could. The appearance of the bike had us stumped. We decided to stick to the performance side and used a fully Aerospace quality constructed carbon fiber quarter fairing, side panels, front fender, and hand guards. Cee Bailey’s Aircraft Plastics also made the black windshield and dark smoke headlight cover that still allows the LED Daymaker light to pass through.

Nothing goes better with carbon fiber than some gloss black paint. I figured I would let the performance of the bike speak for itself, rather than some crazy-ass paint job. Everything used on the bike has a function versus just putting a bunch of pointless stuff on the bike. We used a lot of ARP Stainless hardware where strength and appearance was a factor inside and outside of the motor.

The hand guard setup is a modified MX kit that we have been running on bikes for a couple years with no issues. From riding on the highway and having protection from debris at high speed, getting hit on the street, and being able to keep your hands and controls safe, we are positive they do make a difference.

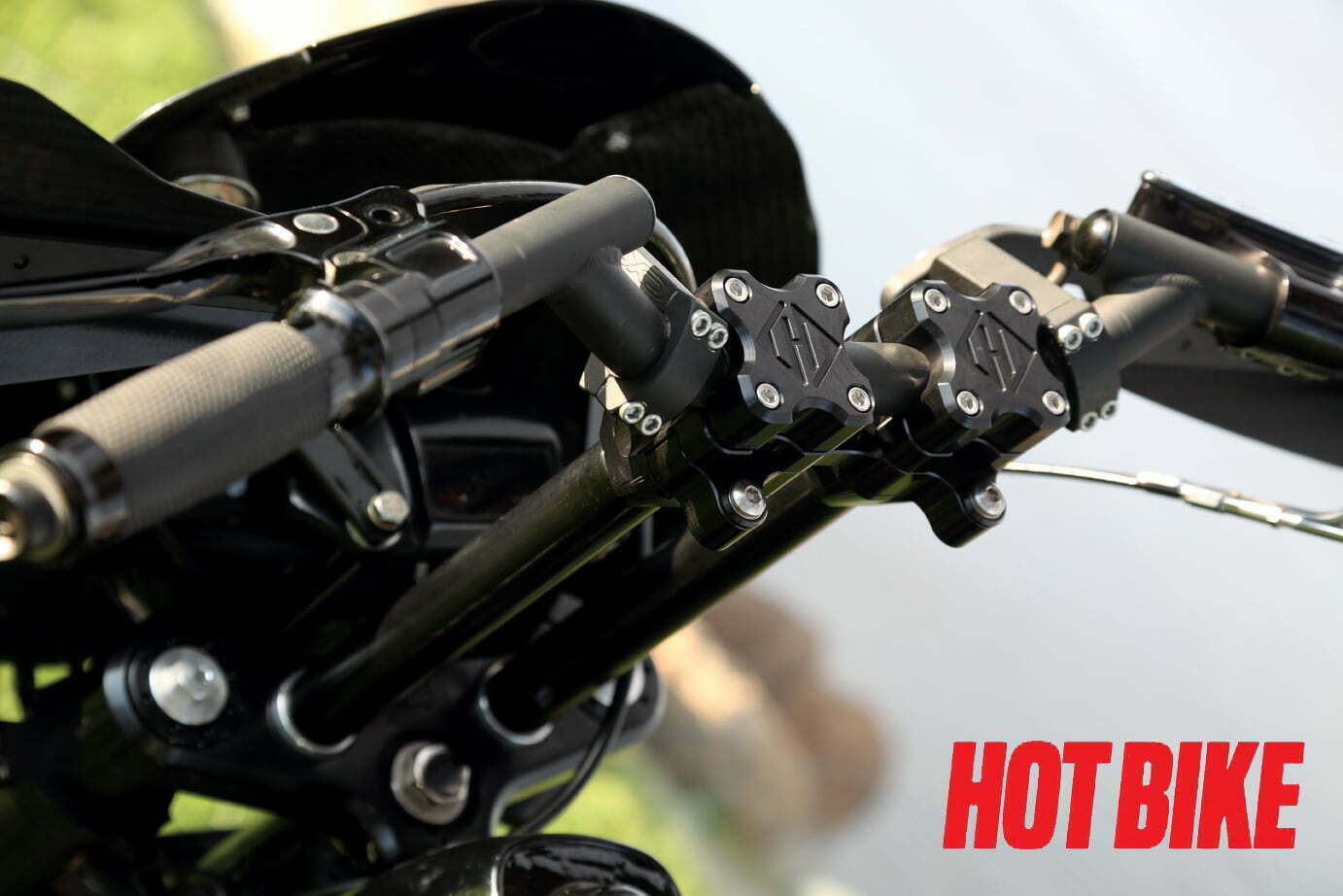

We went with a 12-inch billet riser from Dynamic Dyna that has a really cool integrated gauge mount, were we added a Dakota Digital MCL-3200 that could easily be integrated into the custom wiring harness on the bike. The hand controls are Performance Machine, simple, and do exactly what they are meant to do. Roland Sands gave me some nice black rocker box covers, transmission cover top, and a Clarity cover to show off the Feuling cam plate.

When we were putting the Twin Cam drivetrain into the bike, there weren’t that many options for foot controls. So we got some parts from Boosted Brad, made some changes, and fabricated what we needed to in order to have them higher than stock with perfect foot position and plenty of ground clearance while keeping the overall width within the space of the Todd’s Cycle handlebars and grips used. The seat is an original Corbin Gunfighter that came on another FXR I picked up out of state.

Finally everything had come together with an RB Racing LSR exhaust with 2-inch primaries throughout. Considering the size of the motor and potential for making a lot of power, we wanted to get as much tire as we could on the 18-inch rear H-D mag, so we used a Metzeler 880 150 series tire.

Finally the motor was fired up, and it was time to break it in. Shortly after a few heat cycles, the bike was taken straight to Eric at Bennett’s Performance in Signal Hill for some adjustments before final break-in. We had the bike on the dyno, began to rip on the throttle, and made all the necessary jet changes to the carb to get the right amount of fuel. We also adjusted the Dynatek ignition to keep the motor running reliably and get some good power numbers. A few hours later, we had some consistent numbers and accomplished grins on our faces. We were able to get 135 hp and 125 pound-feet of torque out of the 113-inch motor on 91-octane pump gas. We have been working with some ideas to get some more power out of the bike, so some changes will come, but for now it’s time to ride