Euro iron explained

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

Euro iron explained

Words: Mark Masker, Photography: Courtesy of Thunderbike

“You know what the funniest thing about Europe is? It’s the little differences. I mean, they got the same shit over there that they got here, but it’s just…just there it’s a little different.” Pulp Fiction, 1994

Nearly two decades after that movie came out and I’m still waiting to be able to buy a glass of beer at McDonald’s here in the US. While John Travolta’s Vincent Vega was talking about differences in fast food across the pond, his point works just as well for custom motorcycles. Most of us have glimpsed at least one European custom either at a show, on TV, or in a magazine. No matter how similar a Euro custom might look to one grown domestically, there are little differences, some more tangible than others.

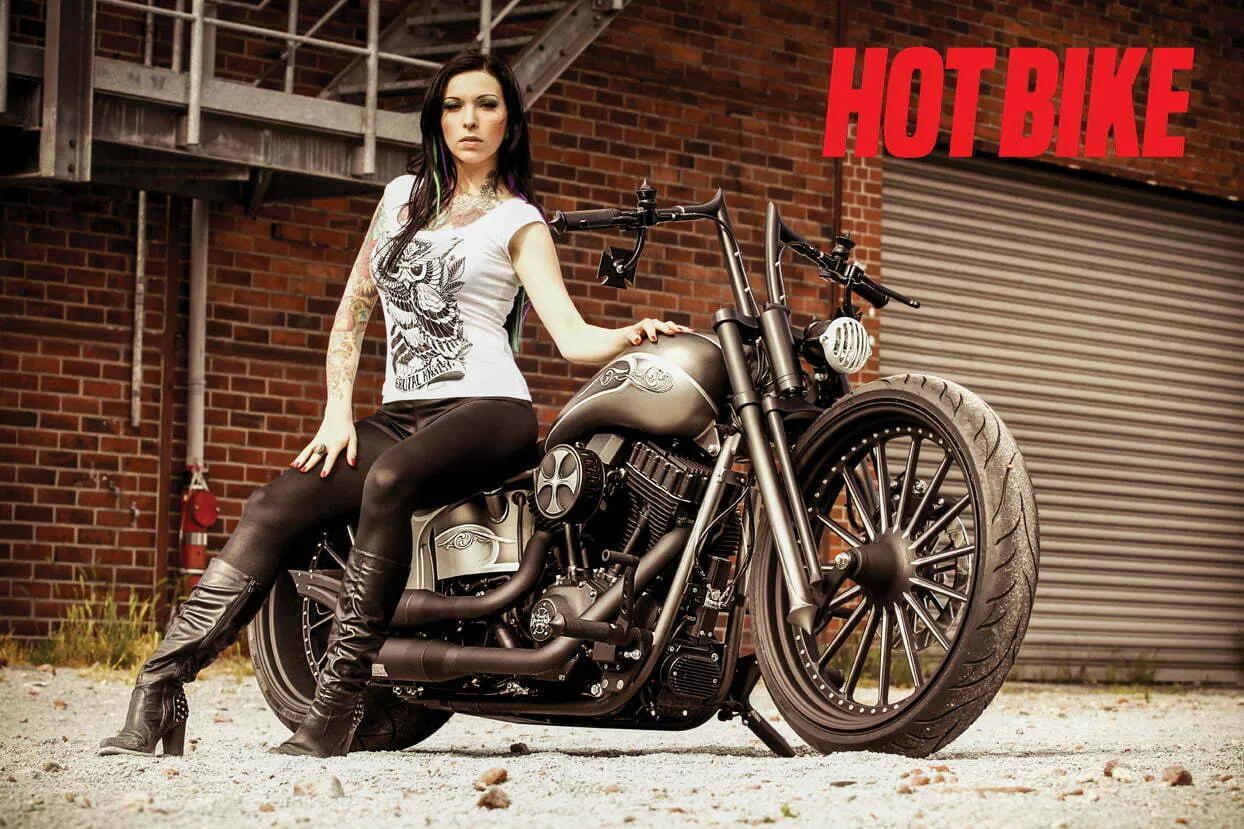

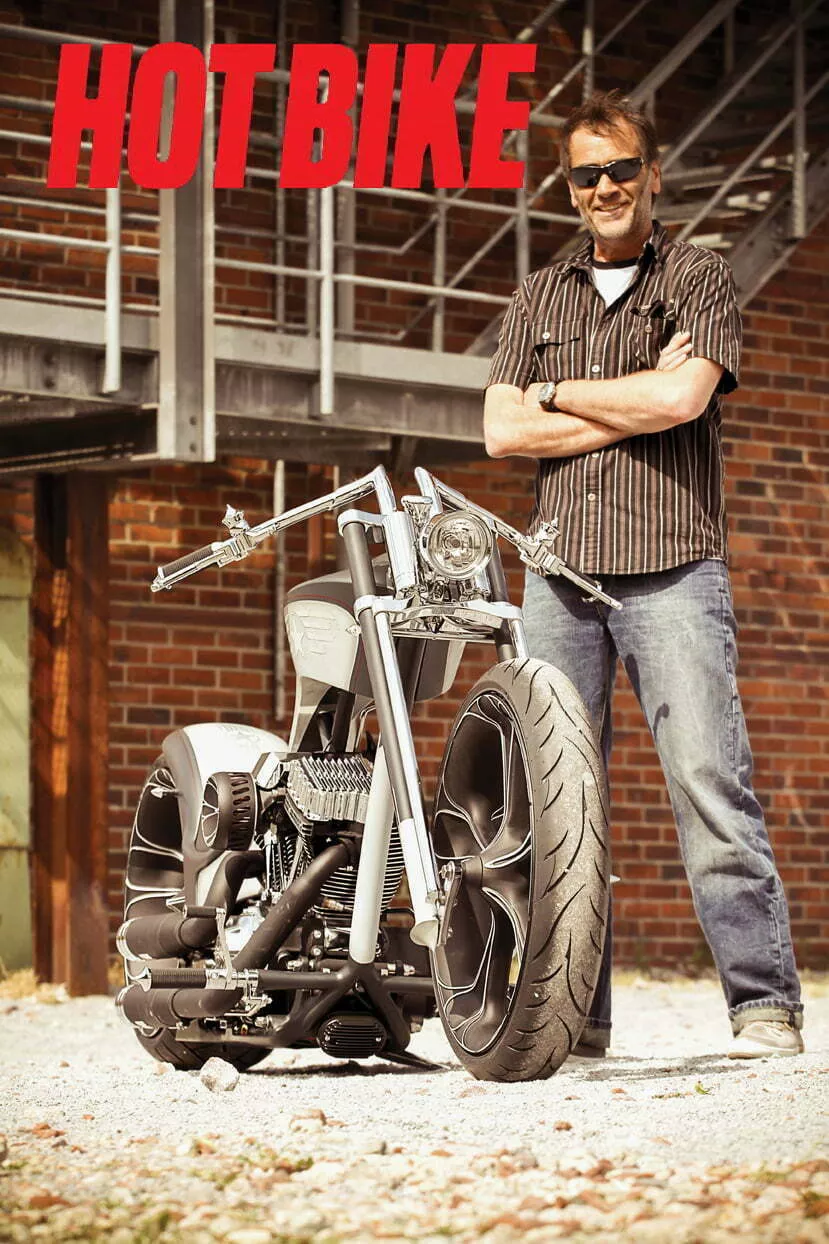

Thunderbike is a shop (and dealership) that knows this really well. How could it not? It’s the largest Harley dealership in Germany, it has made some incredible custom bikes that’d look great no matter what continent you’re on, and it makes its own line of custom products. Andreas Bergerforth founded the company 27 years ago from a small operation in his shed. Since then, Thunderbike has grown into the success it is today. Here’s what Thunderbike had to say about its success, European style, and tougher customization laws overseas.

HB: Why a Harley shop?

TB: We started with Suzuki in the 1980s, built many streetfighters and customized racebikes. In the ’90s we started with custom choppers and cruisers, and when H-D offered us the dealership in 2005 we just couldn’t refuse. Now we have around 60 employees at Thunderbike H-D and 50 more in our Roadhouse [bar and restaurant].

HB: How did Andreas get into riding and building?

TB: Andreas started in a little shed where he repaired and sold used bikes. From year to year the shop became bigger, so there was no real “now we’re building motorcycles” moment. The first custom bike with a Thunderbike frame was built in 2001, which changed a lot here.

HB: Talk to us about your custom frame kits.

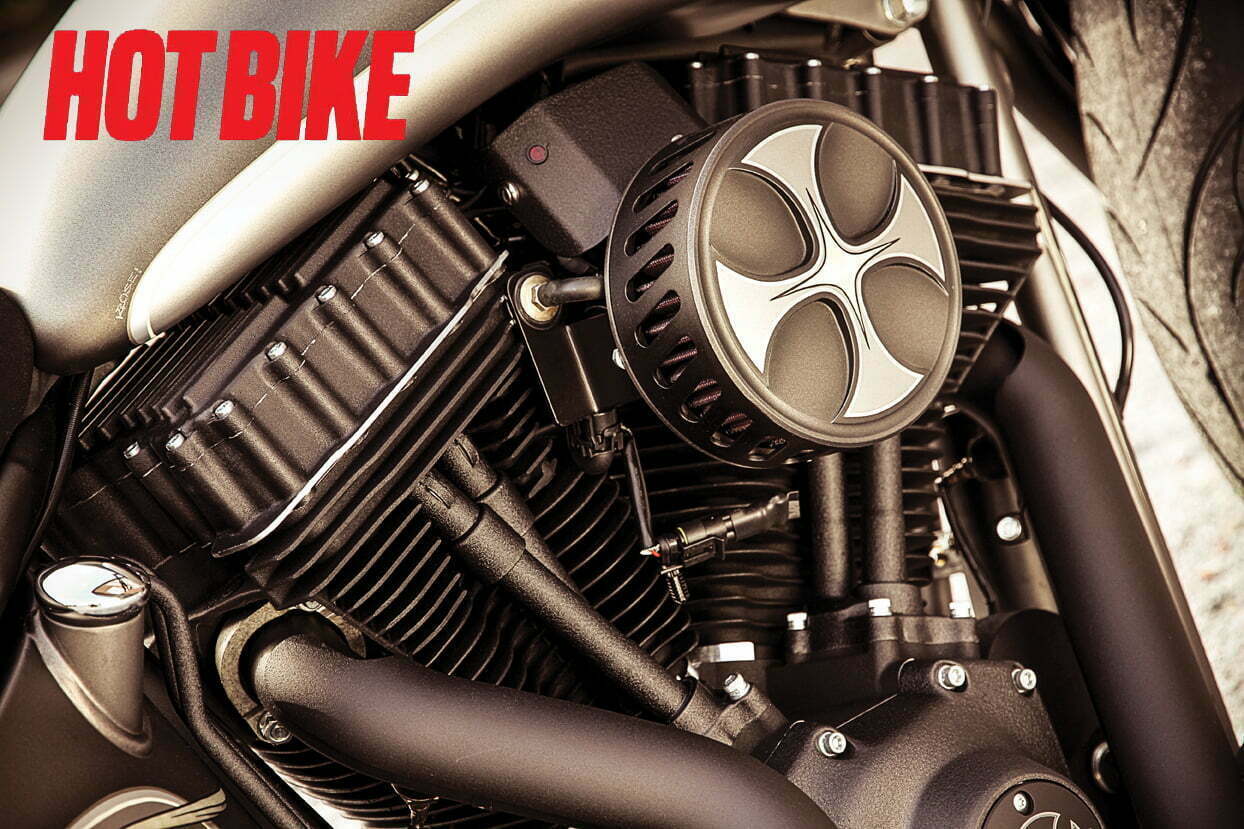

TB: Before we were limited to the stock frames. With our first own frame, we had the freedom to design the bike as we wanted. Today we’re building almost everything on our own. Go to our website and there you can take a look at our frame kits, which are for sale. We’re building everything from low drag style to high necker, most of the stuff for Big-Twins [Screamin’ Eagle 110 is the most common engine here]. We’ve also finished a couple of bikes with metric engines and our frames. The “making of” movie of our Unbreakable shows a bit of what we’re doing. You can find it on YouTube.

HB: How is the European custom aesthetic different from American?

TB: I don’t know if there is a signature mark of European customs because the basic style is very similar to the rest of the world. The “fat-ass” customs are more popular in Europe, whereas the US market goes a bit into the vintage direction. But both the US and Japanese markets are influencing Europe a lot. The regulations here in Europe are a little bit harder, which also changes the styles on the road.

HB: Harder how?

TB: The missing speed limit on the German autobahn may be a reason for modern Big-Twins with stricter regulations. The German TÜV only allows us to mount tested parts to the bike. You’ll also get into serious trouble if you modify stock frames. This makes parts more expensive here because the production series are smaller, and TÜV testings cost a lot of money.

HB: Tell us about your approach to designing bikes.

TB: We usually start with pen and paper to get into the general idea behind the bike. After that we draw a more detailed CAD model so we can watch the concept from any angle and see where we need to do some changes. The entire process is challenging because each bike should have its own character and style. With an increasing number of builds, this is even getting harder to create unique motorcycles.

HB: Do you have a signature part or style for which you’re known?

TB: Most people notice our special wheels with the uncommon 21-inch rear wheel diameter. We don’t want to be into only one special style. Those 21-inch rear wheels are such a special style for us, but Metzeler/Pirelli has not yet brought out a new tire for it, so we have to save up our tire stock. That may be an interesting topic for a story because many riders around the globe are affected by this questionable tire policy.

HB: How is operating a Harley dealership in Germany different than running one in America?

TB: Here in Germany it’s all a little bit smaller compared to the American market. The market share of H-D is lower here, so even as the largest German dealer we would only be of medium size in the United States. The US switched a bit back to its roots in the last five years. One reason may be the financial crisis that made it hard to sell $100,000 bikes in large numbers. In Europe it’s difficult to buy pre-Shovelhead bikes in good condition, so most of the stuff has to be imported. H-D has become strong in the German market in only the last couple of years, so most people are riding Twin Cams and Evos here.

HB: How many bikes do you make in a month? A year?

TB: That really depends on what you count. Projects like the Unbreakable bike need almost a year of time, but we’re also building bikes with our frame kits, that only need around two to three month to finish. Half of the H-D bikes we sell are also modified by us. It starts with exhausts or air cleaners and ends up with a full customization including wheels, swingarm, front end, air ride, and so on.

Source:

Thunderbike Harley-Davidson

thunderbike.de

Phone: (+49) 02852-6777-0