The Power Of EFI | Tuning With The Dynojet Power Vision

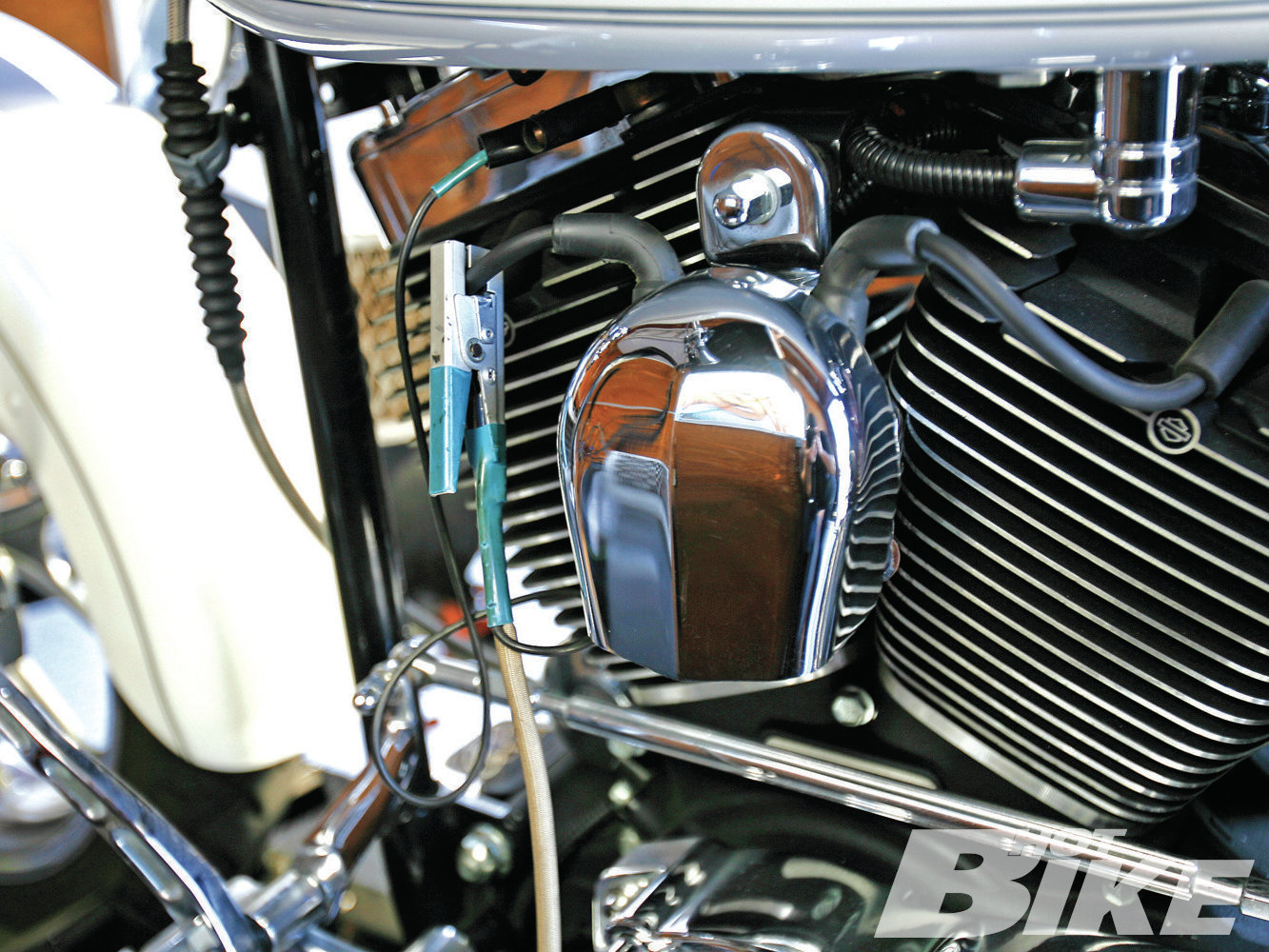

01. With the Softail strapped onto the Dynojet dyno at Anaheim Fullerton H-D, the magnetic pickup for the timing monitor was connected to the front cylinder’s spark plug wire.

02. Using the included self-adhesive hook and loop fastener tape, Patrick placed the Power Vision in plain view on the Fat Boy’s speedometer glass. The vehicle diagnostic interface cable was plugged into the ECM’s diagnostic port under the seat. While running the motorcycle on the dyno, the Power Vision monitored and recorded RPM, throttle percentage, manifold airflow, and intake air temperature.

03. After setting a number of runs to ensure there was sufficient information to alter the tune with, Patrick manipulated the engine tables in WinPV and then uploaded those changes to the Power Vision before running the Softail on the dyno to quantify or disqualify the changes. That process was done again and again as small adjustments were made to locate the perfect settings to make our aftermarket parts work in harmony.

04. The monitor revealed the tale of the dyno including the air/fuel ratio along the whole RPM range. Patrick uses the dyno on a daily basis as a tool for tuning instead of bragging rights. His skill in tuning multiple Harley models along with a myriad of aftermarket components shows in the preconfigured tunes you are able to use without the need of a laptop.

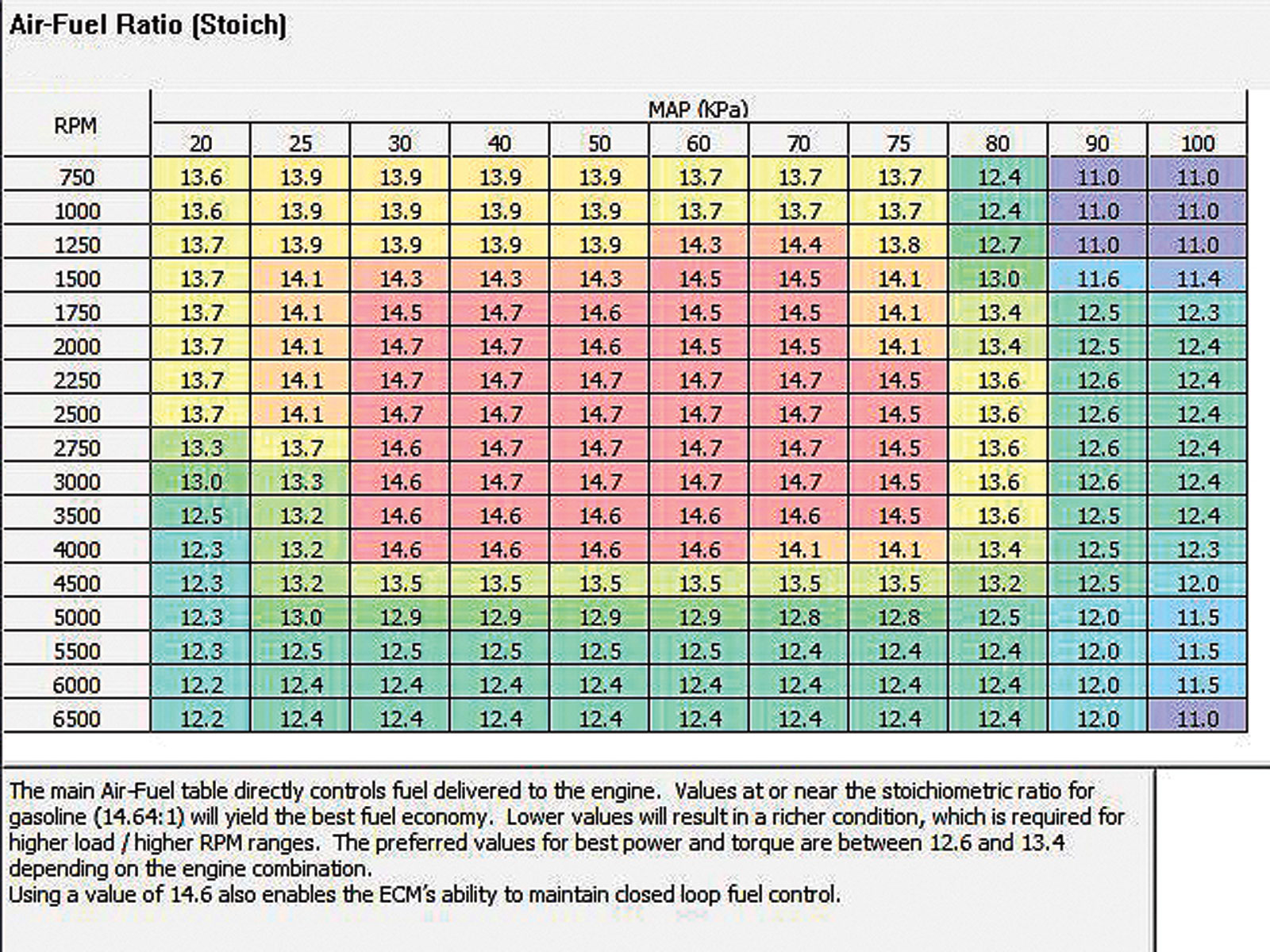

05. When in the WinPV software, this is one of the screens that sees plenty of work. It is the air/fuel ratio screen. Along the top is the manifold airflow pressure and the drop on the left is the engine RPM in 250-rpm increments. Notice how the ratio changes to a richer level based on the engine’s constantly changing load.

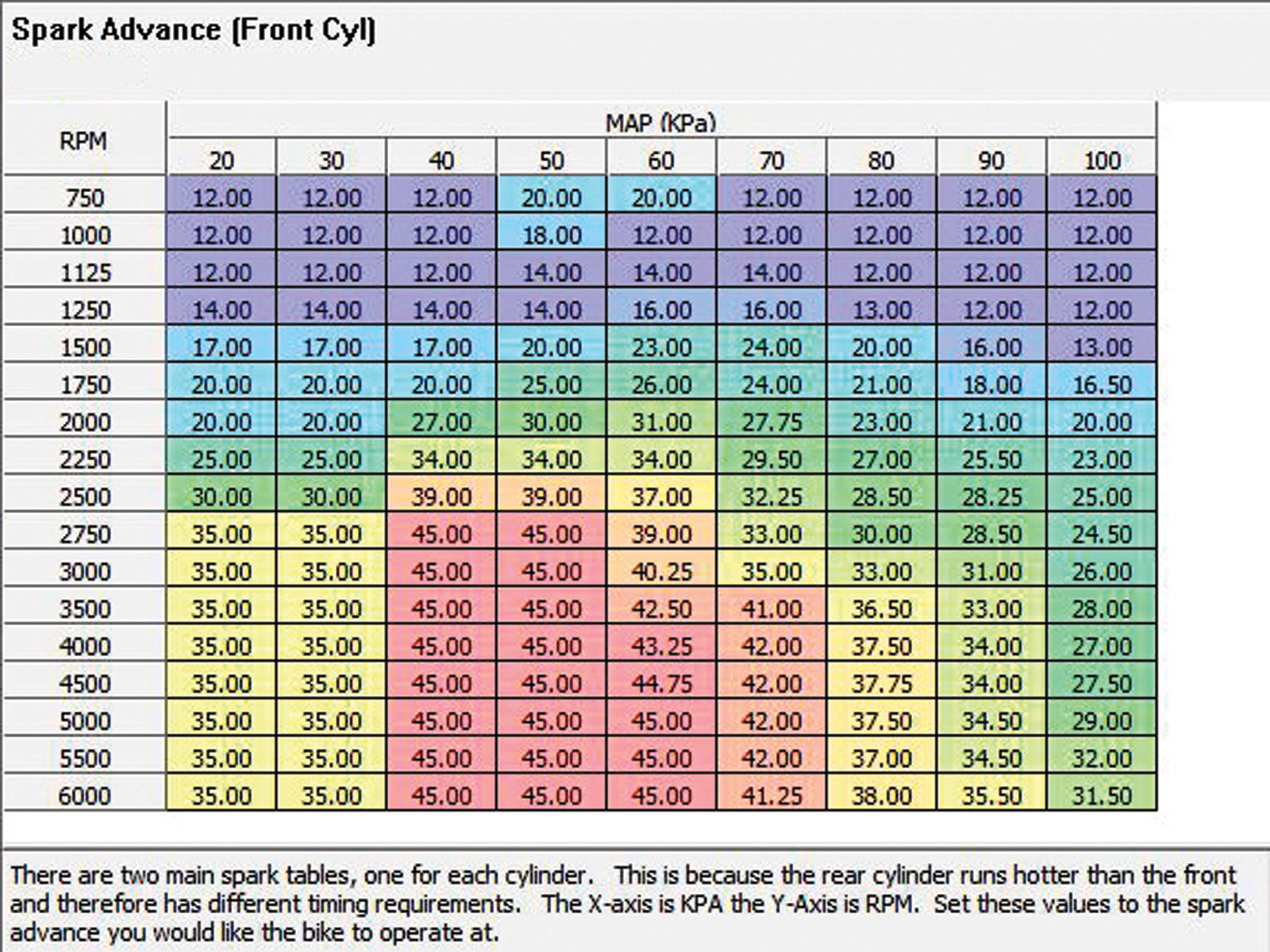

06. Spark advance and timing are altered per cylinder due to their individual needs. The rear cylinder normally runs hotter than the front and requires its own spark timing to compensate for its higher cylinder temperatures and to prevent detonation.

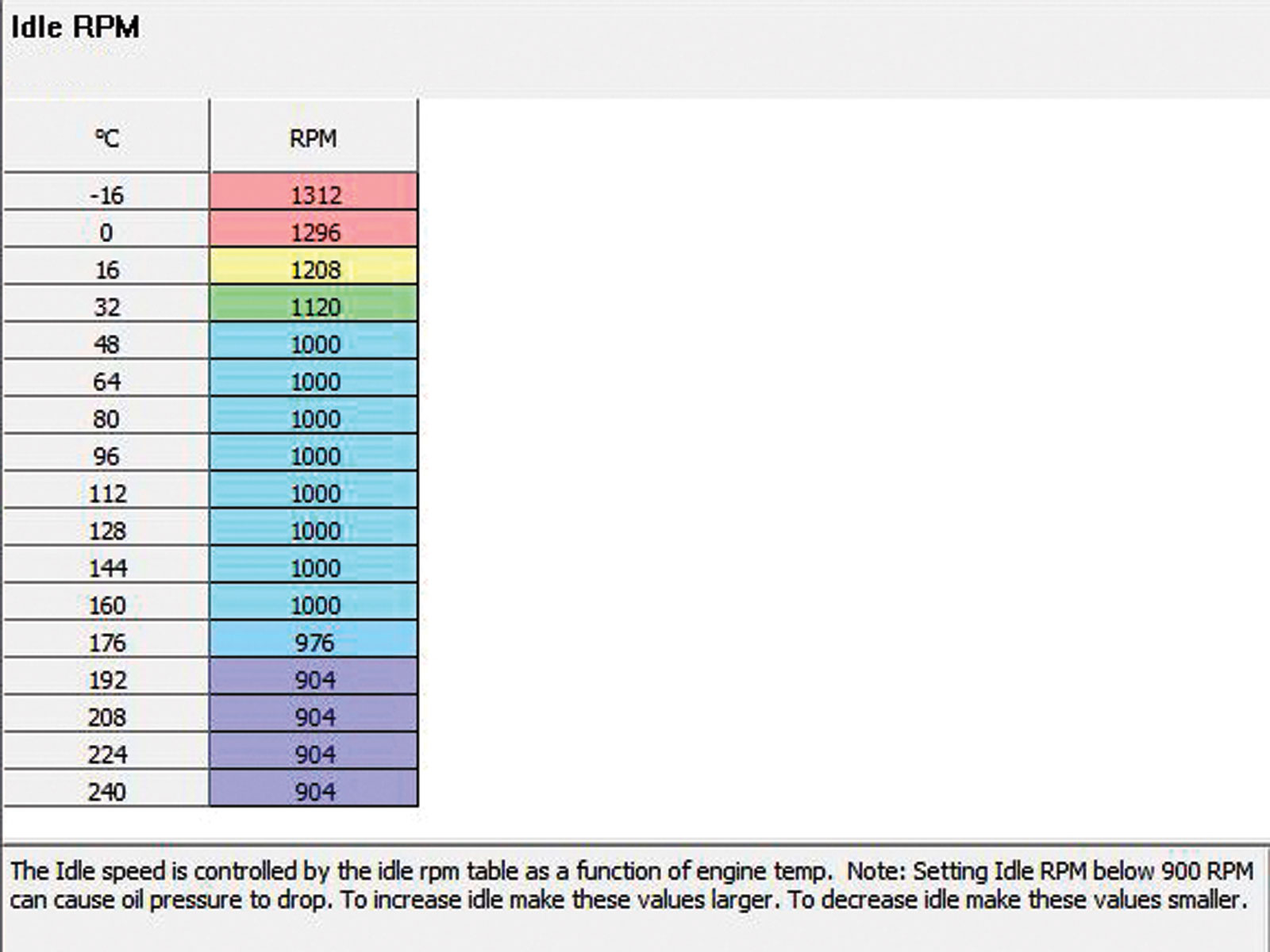

07. One of the most often criticized points of an EFI Harley is the lack of low RPM idle to get that patented thump everybody wants. In the software, idle control is based on the engine temperature, but a warning is given not to go below 900 rpm as it negatively affects oil pressure. As you can see, a setting of 904 rpm at operating temperature is programmed to allow for proper oil pump functionality.

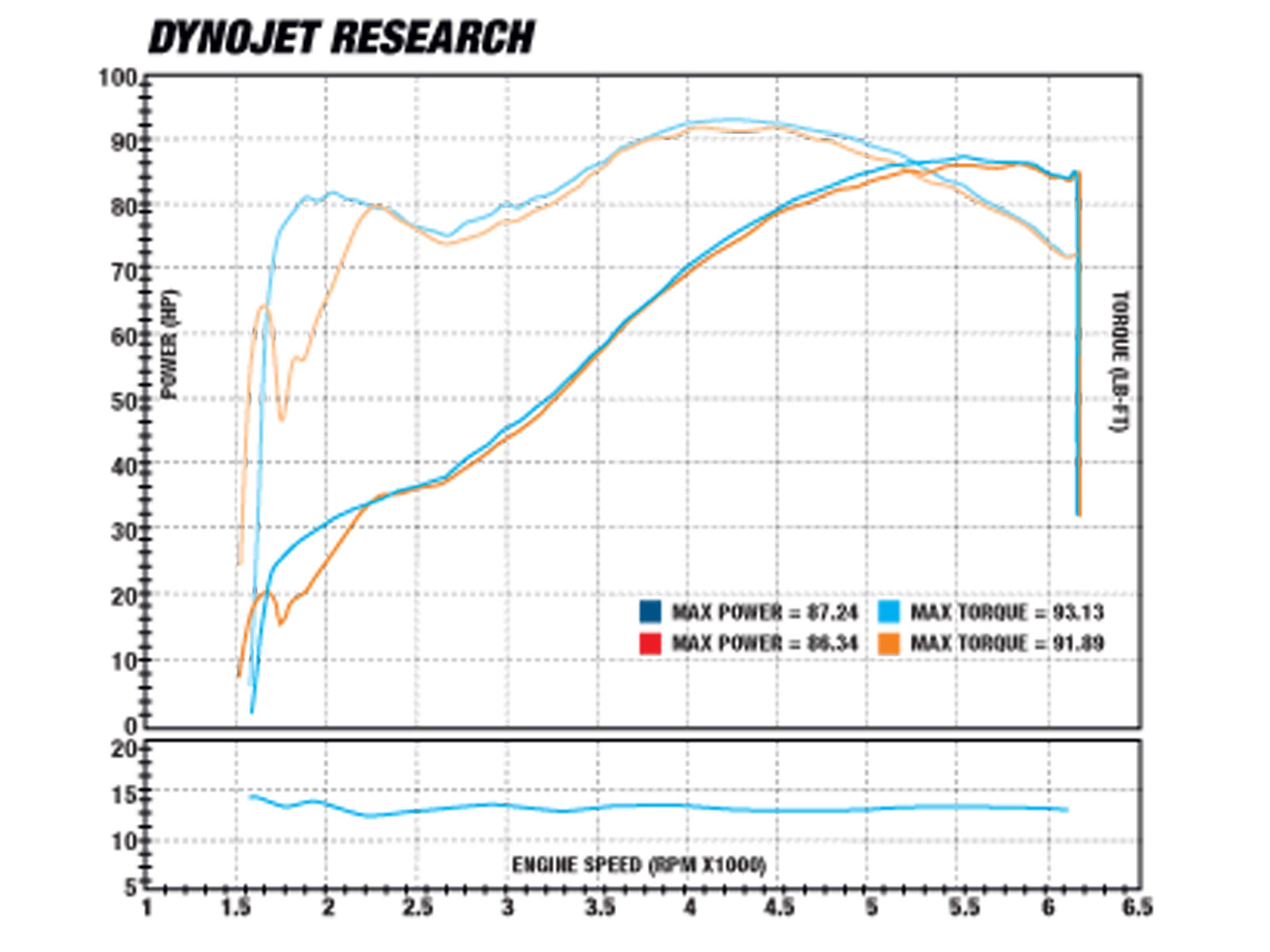

08. Our before and after didn’t change much at peak due to the preconfigured tune being already close to perfect, but we did manage to fill in a nasty hold at the bottom of the range between 1,700 and 2,200 rpm. With our fuel and timing curves cleaned up, the final numbers on the 88-inch with SE intake, V&H; exhaust, Lunati cams, and Dynoject tune came to 87.24 hp and 93.13 lb-ft of torque.

09. Dynojet also offers an Auto Tune kit ($420-$429) for the Power Vision. Once installed the Auto Tune kit monitors the fuel mixture with Wide Band 02 sensors in the exhaust and works in combination with the free Log Tuner software to monitor, create data logs, and make changes to the fuel map, and then the user can apply the .PVT file that is sent to the ECM. Lastly, a new Quick Tune will soon be built into the Power Vision, so no lap top will be needed to use either the stock narrow-band 02 sensors or the Auto Tune Module to make data logs, see fuel trims, or changes to the map.

There seems to still exist a shroud of secrecy enveloping the magic hidden inside your Harley’s ECM. It’s as if many of the current owners of the EFI generation of Harley motorcycles simply choose to believe that tuning a computer-controlled machine is far outside their realm of comfort. The far better reality of electronic fuel injection (EFI) is the near infinite range of adjustments that can be utilized to properly tune your machine for any and every part imaginable available today. Yes, it takes some getting used to so you know what parameters you are working and what each of them does to your V-twin’s engine. With a little can-do attitude and the proper help, you can do it yourself.

Helping us DIY types is the Dynojet Power Vision (PV-1 $549) tuning module. By utilizing the touch-screen Power Vision, you can download and store different tunes that can be flashed to your bike. The easiest way to tune your H-D is to use the Dynojet preconfigured tune files. Very simply, the Power Vision identifies your bike’s information and automatically sorts applicable dyno-proven tunes for you to choose from. Hundreds of tunes are available and then organized into relevant categories such as stock improved, air intake kits, slip-ons, full exhaust systems, cams, etc., for ease of your use. You can also get one-off tunes uploaded by a custom tuning shop, or received via email and load them right on the device to be further tweaked or directly downloaded and run. The Power Vision holds up to six tunes for you to choose from at your convenience, and these can be replaced as many times as you like with updated tunes. One of the cool things about the Power Vision is that it will save your original ECM settings so that if you ever want or need to go back to stock you can do so. Check engine light came on? You can also read and erase diagnostic codes with the handheld unit.

For our intents and purposes, we’ll be focusing on the custom tuning aspects of the Power Vision and Dynojet’s included WinPV tuning software. After installing a set of Lunati camshafts in our ’04 Fat Boy, we originally used a Dynojet pre-configured file based on our Softail’s mods to get us close to correct and up and running with little fuss. We knew there was a little more to be found and we wanted everything tightened up just a bit to make our engine run perfect. With the advanced features of the Dynojet and its Windows-based WinPV software, we can alter nearly all the engine’s parameters by each cylinder. Adjustments controlling spark timing, fuel trim, idle RPM, and volumetric efficiency are at hand in the software’s function screens, giving you the power to ultimately fine-tune everything from a stock engine to a high-performance V-twin. Thanks to dyno time at Anaheim Fullerton Harley-Davidson and a visit from Dynojet’s Technical Advisor, Patrick Daniels, we got a peak behind the secret veil of EFI computer controls. HB

Source:

**Anaheim Fullerton Harley Davidson **

(714) 871-6563 | harleyfullerton.com

Dynojet Research

(800) 992-3525 | dynojet.com