Remanufacturing Evolutions By Harley-Davidson

The engine is inspected upon receipt and the VIN number verified. Wendy has an overhead electrical chain hoist to help her move the engine onto her work station-lucky girl.

All polished and chrome parts are replaced with new ones. Usually the engines are shipped with no oil. The dealership should drain all fluids before shipping. The VIN on the old crankcase is destroyed, and the customer’s original VIN will be stamped on a new crankcase when the reman engine is assembled.

Oil pump gears are checked for clearance, fit, and cracks. This is a cool process. Imagine if every engine was checked to this level of precision after 50,000 miles?

The Factory uses a number of measuring devices to determine the wear and tear on engine components, including this pinion shaft.

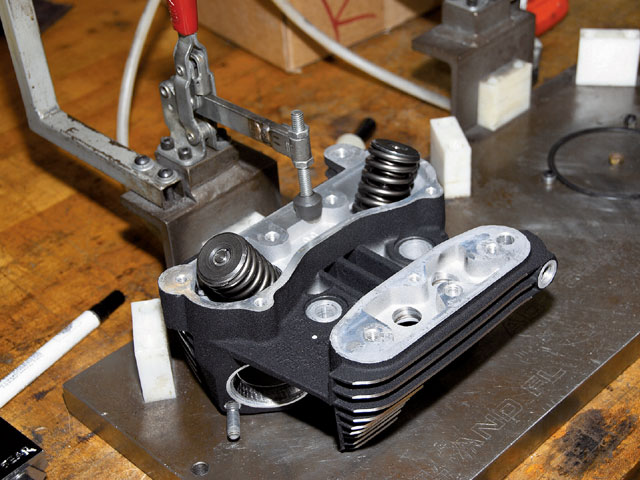

Unless there is severe damage to the heads, all the valve seats are re-cut and checked.

We old builders avoided oversized valve guides because we were determined to make a set of heads last forever. We would carefully heat and tap out the old guide and pray the new stock guide would fit as tight as a boar’s ass. The Factory knows the average rider won’t put 200k on a given engine and two 200k engines would last most guys a lifetime, so the Factory pressed in a new set of oversized valve guides and assembled the valves and springs to the heads. We were taught that if the clips aren’t inserted properly between the collar and the valve, disaster could strike. It’s critical. Each cylinder is vacuum-tested to check for combustion chamber leaks.

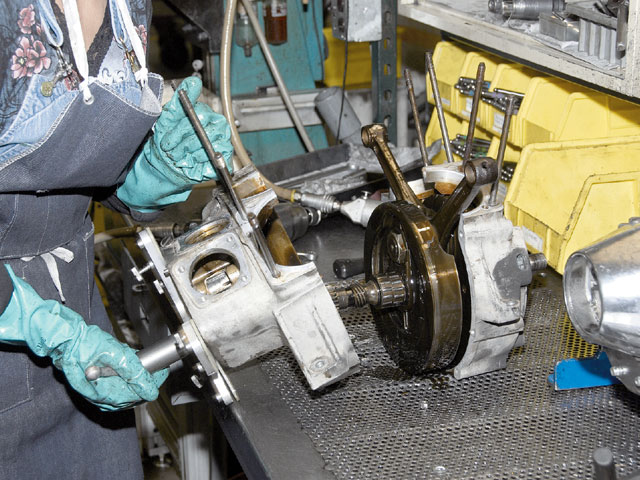

Next, we take you to the engine case station, where Denise and Jeff refit an entire engine. Since our original cases were not used, the original VIN and serial numbers on the engine crank cases were stamped into the new cases.

On the drive (or left) case Jeff pressed in the new Timken bearing race. It’s interesting to note that late model Twin Cams don’t run Timken bearings on the sprocket shaft, but shifted back to the old roller style from the Panhead era (like the ones used on the pinion shaft side here).

Although the Factory doesn’t reman the carb, fuel injection, alternator, or ignition systems, they rebuild the oil filter mount and system.

Here’s the process of putting the new oil pump elements together. We were curious to see if new components or refurbished parts were used. Harley oil pumps have basically stayed the same since 1936. These gears drive off the pinion shaft, picking up oil and sending it on its way throughout the engine-a simple but delicate operation. “The following pump parts are refurbished and/or inspected and reused if they meet our specifications,” said Scott Miller. “These parts would be gears, pump body, pump cover, driveshaft. All other pump parts are replaced with new.”

Denise checks the pinion shaft run-out one final time. The wheels have been trued and balanced, but she double-checks them, then pre-oils the crankshaft bearings and the pinion and Timken bearings as the final assembly takes place. At this point Denise torques the cases together. They use silicone-based RTV sealant to seal the cases.

Pistons can run oversize, 0.010, 0.020, or 0.030-inch. Here, Mark begins the process of installing the three-piece oil rings. Each ring has a particular position for the ring gap to insure they don’t line up to allow oil into the combustion chamber or compression into the crank case.

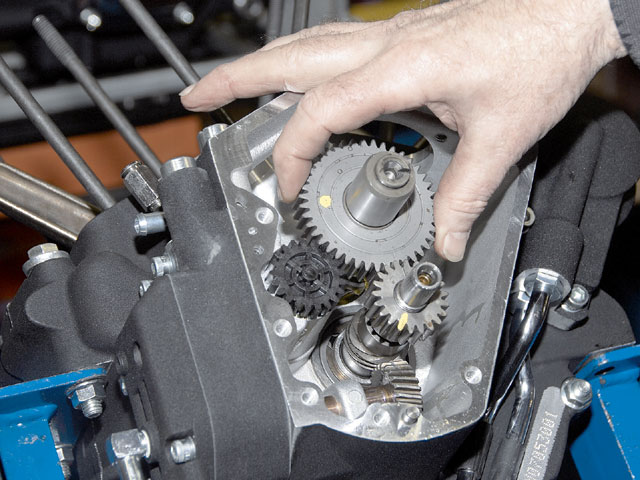

Mark installs the worm gear first on the pinion shaft. It drives the oil pump. Then he installs a spacer and the pinion drive gear that drives the cam. Ignore the yellow paint. The color indicates that these particular gears fit well together. Each gear, the pinion, the breather, and the cam gears contain notches. They must all be aligned with each other for proper cam, breather, and ignition timing. Mark applied a dab of red Loctite before torquing the pinion nut (35-45 ft-lbs torque). Then he oils the gears in the cam case before he starts to close it. He also checks the cam endplay. It needs to be within 0.050-inch.

Mark installs the lifter blocks with new gaskets and torques them to factory specs.

Mark assembles the pistons on the rods. Of course, they have the coolest special tool to install the wrist pin keepers. Mark checks the overall wrist pin run-out between insert clips to insure both keepers are securely installed.

Mark installs the cylinders over the piston rings. Note the wheel on the sprocket shaft, so he can reposition the pistons at any time. Also note the Teflon slab under the piston to allow it to set flat while the rings are pinched with the special tool and the cylinder is lowered. After all the rings are in the cylinder comfortably, the wheel can be turned so the piston is lifted enough to remove the ring compression tool. Then the cylinder can be lowered into its final position.

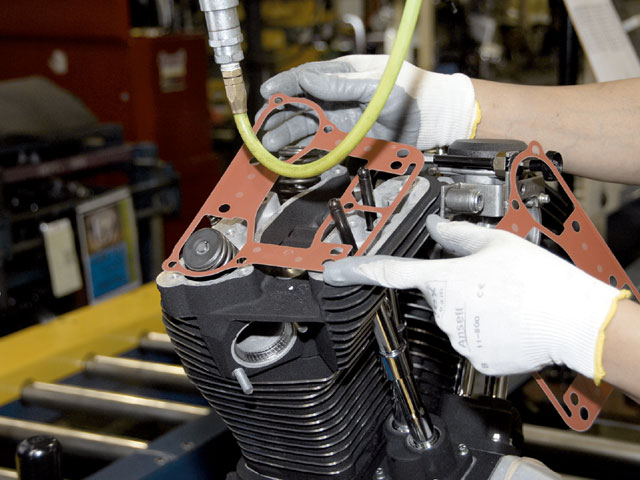

We face a station shift change here, and the delightful Etta takes over to install the heads after she slips on fresh gaskets. She has a machine that torques all the headbolts at once. “This follows the same three-step sequence found in the service manual; however, all eight bolts go through the sequence all at once,” Scott added.

Now Etta drops the pushrods into place. There’s specific pushrods (of differing lengths) for each valve. No adjustments are necessary. Next she slips on a fresh rocker box gasket and prepares to seal up the engine. Etta torques the rocker box and cover screws to 15-19 ft-lb. The smaller Allens to 10-14 ft-lb and the top cover fasteners to 90-120 inch pounds.

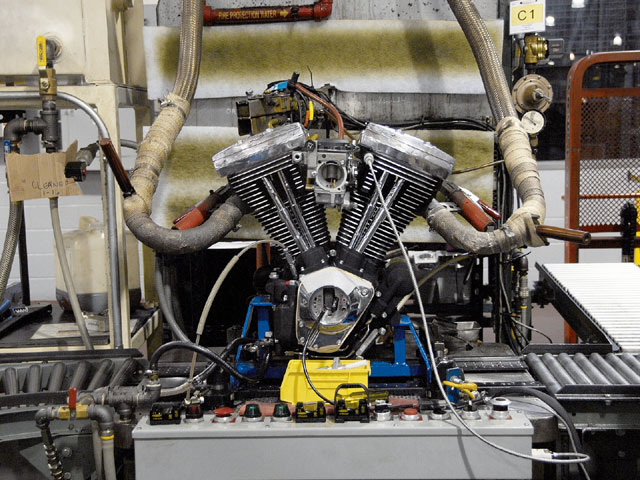

We can’t see it, but Etta installed a sprocket to start the bike for testing, then turned the engine around and set the timing. “We monitor oil pressure at different rpms, and temperature,” Scott filled us in. “We also check for leaks and weeps after the motor reaches temperature. The exhaust system on the test booth muffles the exhaust to the point that it can hardly be heard at all. This allows the test mechanics to hear any unusual mechanical noises.”

After inspection and packaging, a worker goes on the CCX internet site and processes the shipping of the engine immediately. When we checked our test engine at Fullerton, CA, Harley-Davidson, it looked virtually new again.

We jumped at this opportunity to cover the Harley-Davidson factory Evolution remanufacturing process from start to finish. If you have an engine remanufactured by the factory, removed and replaced at a dealership, your warranty is restored. The factory is also capable of remanufacturing your original powerplant or replacing it with a new, very reasonably priced unit containing your original VIN. Options such as chrome or polished engines are also available.

It starts with your dealer removing your engine and shipping it to the Factory’s Capitol Drive Facility in Milwaukee. When it reaches the factory, they will unpack and prep it for disassembly. The process from the factory costs $2,000 for an Evo engine and $2,200 for a black and chrome job. Your dealer will probably also charge you for R&R.; Twin Cams are slightly higher, but there’s more options. You can ship your Twin Cam engine and the factory will install a big bore kit and reman your engine at the same time.

The new engine and reman program started in 1999, and it takes only two weeks from the time your baby lands in Milwaukee before it’s shipped back home. The factory runs through about 1,500 reman Evos a year and sells almost 2,500 new engines. Quality engine parts can be remanufactured to original specs and saved, while others are discarded. All reusable parts are cleaned and freshly powercoated. Reusable parts are machined, rehoned, and rebored to exact tolerances, and then passed through rigid specification checks.

Crankcases are set, bearings pressed, and parts reassembled. Chromed and polished parts are replaced. Each engine is upgraded to meet the latest specifications where possible. For compliance and warranty program acceptance, all engines will be built with stock camshafts. If you have installed performance cams, they will be discarded and replaced with the stock versions before your engine is returned. You might consider installing a stock cam before beginning this process.

Each remanufactured engine is hot-tested to Harley-Davidson standards. If it passes, it receives a one-year unlimited mileage factory warranty. After the running test engine was reman’d, it was packed for shipping back to Fullerton Harley-Davidson. We hired a reporter who snuck into the Harley-Davidson Capitol Drive facility in a box of parts and photographed the entire sequence of remanufacturing procedures.

We found this whole process fascinating. The remanufacturing system allows the factory to inspect the wear of many engines, determine how well they performed, and find their weaknesses. Since Twin Cam engines can also be remanufactured, it would be interesting to know which engines hold up better. We’ve always liked the Evo engine (and so does the aftermarket) for its simplicity.

We spoke to Scott Miller, the man in charge of the reman program for Evolutions and Twin Cams. He’s also in charge of the new engine building program, including Evos, Twin Cams and big-inch Twin Cams. We quizzed him about wear and tear, what survives, and what fails. “We record and document failure codes,” Scott said. Unfortunately, he couldn’t tell us if the Evo lasts longer than the Twin Cam or what is weak or strong in their engines. “But I can tell you that if a rider is reasonable with his engine during use and changes the oil every 2,000 miles, he will get a lot more riding out of it.”

He also told us many riders go for the $2,000 reman just to freshen up engines and have the components powdercoated for a much more durable and long-lasting finish. Before 1994, engines weren’t powdered at all. He also pointed out that all the cosmetic components are replaced with new parts including chrome.

Enjoy this process. When our engine was returned, it was virtually new again.

Zipper’s makes a kit to exchange the roller style bearings back to Timkens for Twin Cams. Harley is satisfied with the roller style even for their 110-inch Twin Cam engines. Jeff is also responsible for pressing in a new cam bearing. “The Evo cam bearing used in all reman engines is the most recent bearing used in Evolution production in 1999,” said Scott Miller from the factory. “This is the same situation for any other common parts-they are always updated to the latest and greatest.”

Sources

Harley-Davidson

www.harley-davidson.com

Anaheim-Fullerton Harley-Davidson

www.harleyfullerton.com

714.871.6563