Top End Refresh: Part Two | Bennett’s Performance Cylinder Honing

01. Here is the ’95 Road King awaiting its reconstructed heart. Tune in next month for final assembly of all of the parts: Branch-O’Keefe’s heads, Bennett’s honed cylinders, Andrews EV27 camshaft, +0.005-inch Harley pistons, JIMS adjustable pushrods, lifters, breather gear, and chrome head bolts. And to seal everything up, a Cometic top-end gasket kit will be used.

02. Starting with the rear cylinder (both cylinders receive the same treatment), Eric thoroughly cleaned the gasket surface with a bead blaster. He then placed torque plates on the cylinder and torqued them to 30 lb-ft. The torque plates provide the same force as if the cylinder was installed on the engine case with the cylinder head attached.

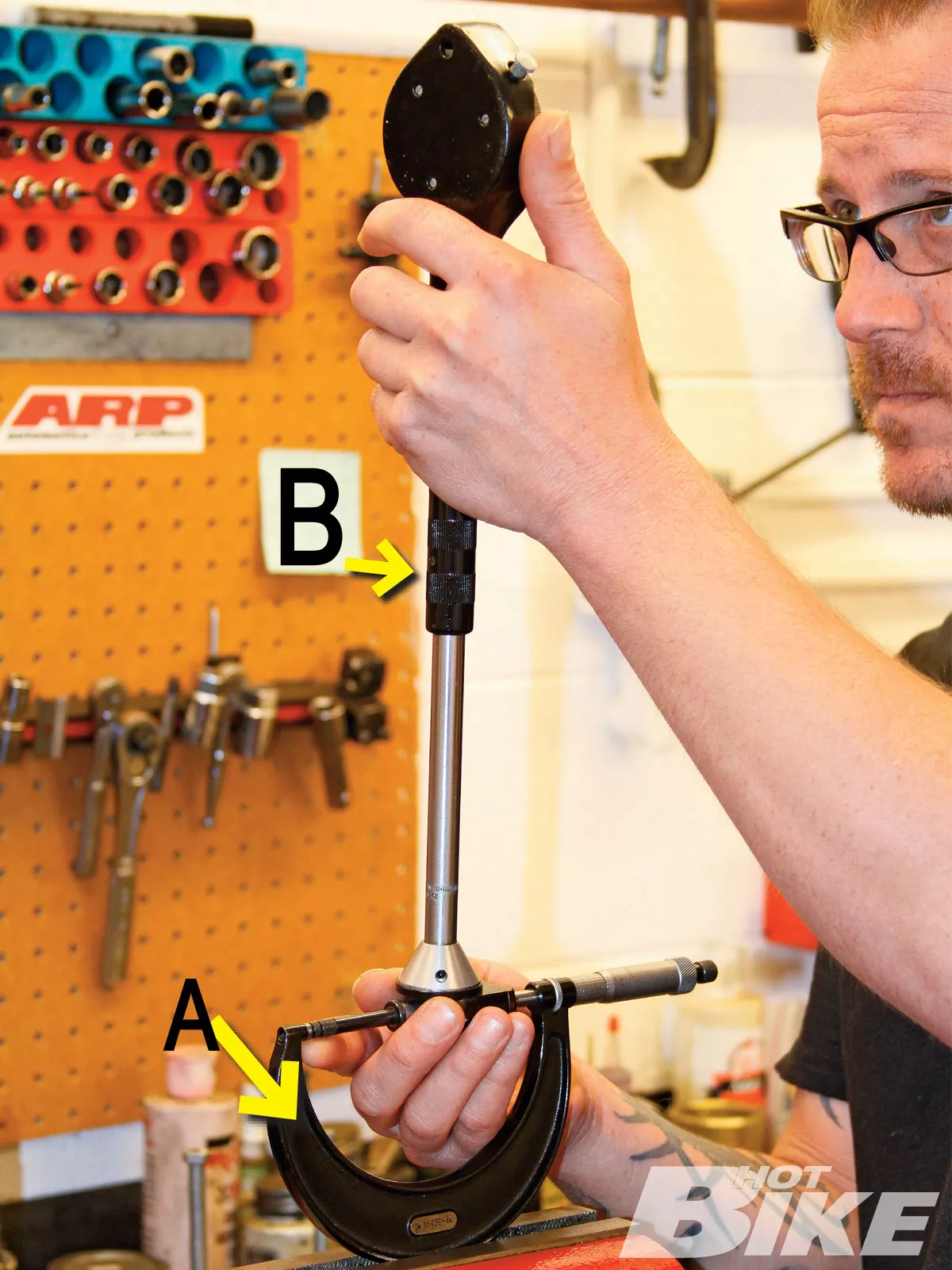

03. Eric measured the new H-D pistons with a micrometer to make sure they were exactly +0.005-inch over stock. It’s always a good idea to double-check piston size so that the exact amount of material is removed from the cylinder wall during the boring/honing process.

04. The micrometer (A) was then used in conjunction with a dial-bore gauge (B) to measure the cylinder wall and how much material would need to be removed via the honing process.

05. The dial bore gauge was measured on the X and Y axes of the cylinder wall to check for taper (bigger or smaller circumference on top or bottom) and roundness (perfectly round). Everything checked out. Because the micrometer was zeroed out with the +0.005-inch piston measurement, Eric reached a -0.005-inch measurement with the dial bore gauge inside the cylinder, so he knew he’d have to remove 0.005 inch. He also needed about 0.001 inch for piston-to-cylinder clearance, so the total material to be removed from the cylinder was 0.006 inch.

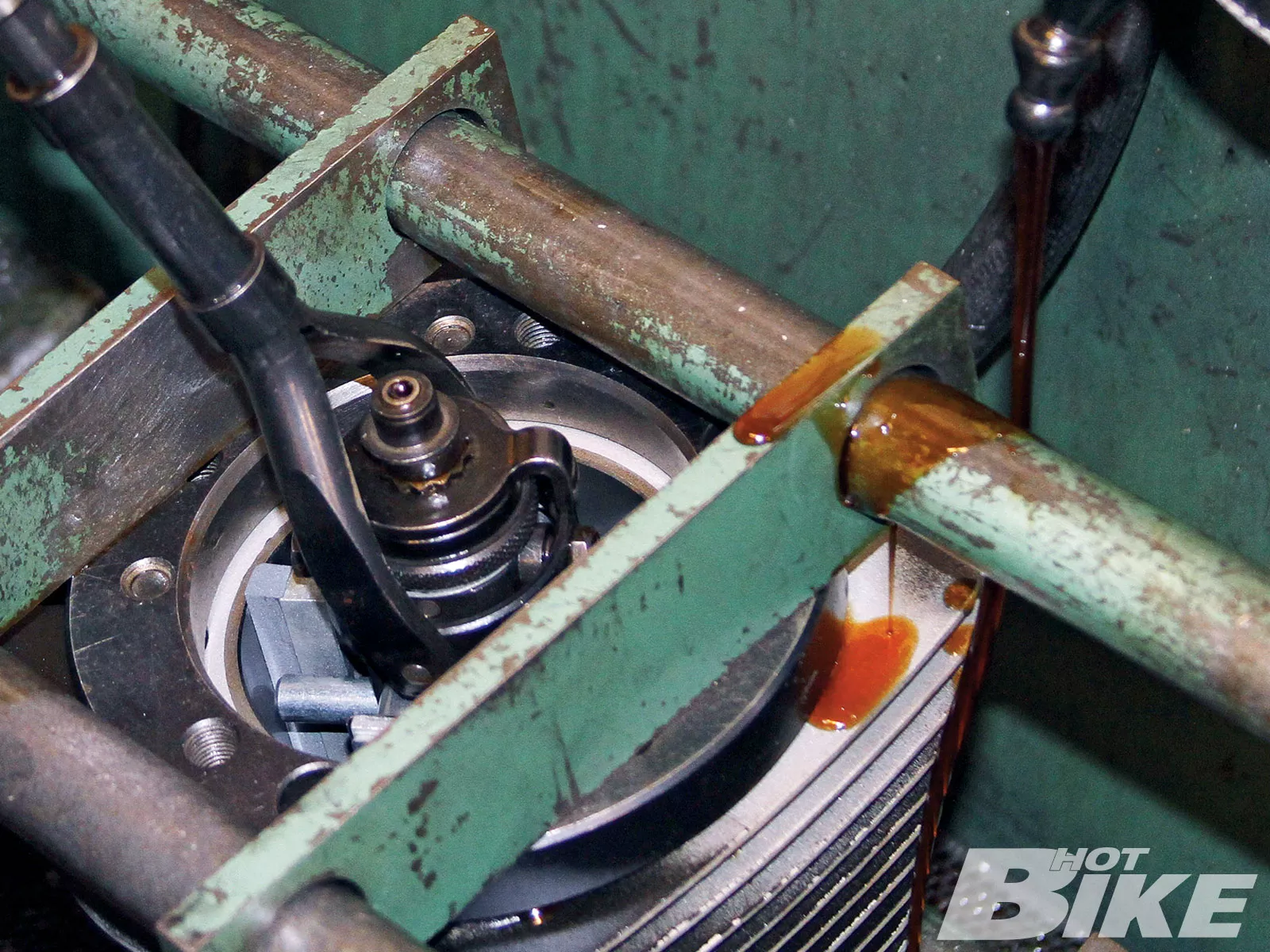

06. Eric hooked up the 280-grit honing attachment to a hand drill and started the process. Honing oil was constantly circulating during honing to keep the cylinder cool and lubricated and to also remove debris. Here’s a shot of the honing slip (arrow), which acts like sandpaper in a way. Moving the hone up and down, Eric is basically scratching the cylinder walls to form the crosshatch pattern so that the scratches cross each other at a 60-degree angle. This crosshatch pattern retains lubricating oil to prevent galling and helps break in the new piston rings.

07. Eric constantly measured the bore with the dial-bore gauge throughout the honing process to check for accuracy. He’s bored and honed tons of cylinders in his days, and he’s pretty damn good at what he does. Once he achieved the correct measurement on the dial-bore gauge, he was done honing the cylinder.

08. After the honing process was completed, Eric thoroughly washed the fresh bore with soap, hot water, and a mild scrub sponge to remove any debris. The cylinder was then completely dried using an air hose and the bore was treated with WD-40 to prevent rust.

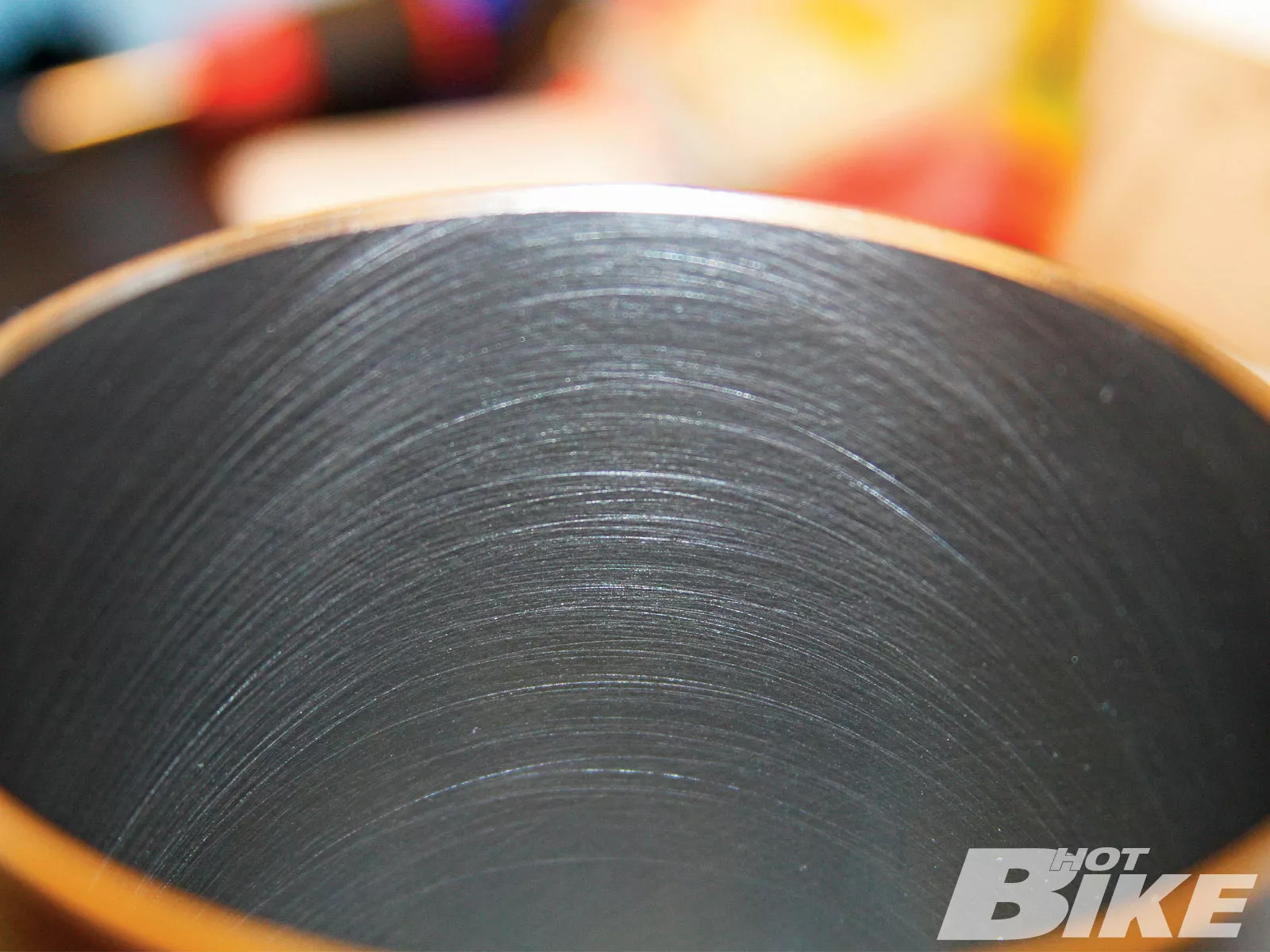

09. Here’s a shot of the crosshatch pattern in the bore. You can’t see the peaks and valleys achieved here, but it is essential in preventing oil consumption and proper piston ring seal. Note: Do not try to perform this procedure at home. Consult a professional to perform the honing procedure.

10. Next month, we’ll move on to final installation as we piece together the Road King’s refreshed top end. We’ll also provide you with dyno runs to show you how well the updated top end performs. Stay tuned!

Freshening up the top end on your motorcycle can drastically improve its lifespan. We have a ’95 Road King with 60,000 miles that needed some TLC.

Last month we took you through part one of this three-part series where we removed the ’95 Road King’s top end, giving the cylinder heads to Branch-O’Keefe to reshape the heads’ combustion chamber, which increases compression, and to port and polish the heads, which flows air more freely and unobtrusively.

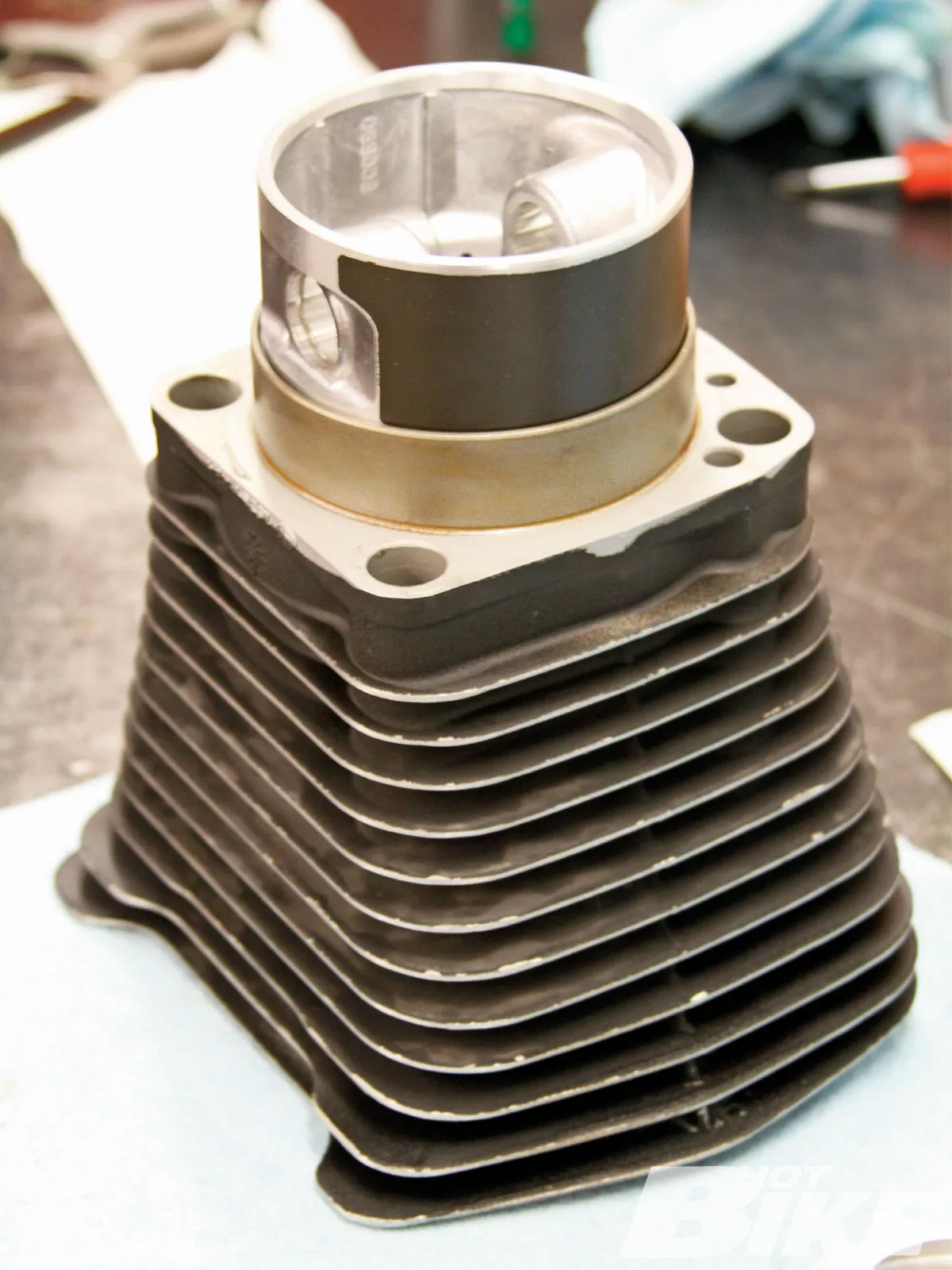

This month for part two, we headed to Bennett’s Performance to hone the cylinders in order to accept the new +0.005-inch (five thousandths of an inch over stock) Harley flat-top pistons. The bike’s owner stumbled upon this Harley flat-top piston kit (Teflon-coated cast aluminum pistons, clips, rings, and pins; about $150) in his garage so the JIMS +0.005-inch flat top pistons that were to be used originally weren’t needed.

Normally, cylinder boring (most commonly done on a machine called a boring bar, but can also be performed on a lathe or a mill with the right attachments) needs to happen when using at least +0.010-inch over stock pistons or larger, according to Eric Bennett, owner of Bennett’s Performance. In this case, boring could potentially remove too much material for this project, but when Eric does bore a cylinder, he uses a Kwik-Way automotive-style boring bar with a motorcycle-specific triangle plate attachment to remove thousandths of an inch of material from the cylinder in a matter of minutes. The machine is similar to a drill press in that it’s lowered into the cylinder with titanium nitrite coated cutters to remove the desired amount of material very precisely and accurately. Once the desired amount of material is removed via the boring bar, the honing takes place.

Honing is basically the refining process of the freshly bored cylinder. Since Eric only needed to remove 0.005-inch from the cylinder, honing was only necessary for this application, and since the honing machine removes material while simultaneously creating the necessary crosshatch pattern inside the cylinder walls, it essentially kills two birds with one stone.

The hone is a tool consisting of multiple fine abrasive slips (picture a beater attachment on a cake mixer) that are rotated via a drill to impart a smooth finish inside the cylinder. There are varying coarse hone slips available depending on the application, but in this case, Eric only needed a 280-grit hone. The hone is moved up and down inside the cylinder to create a crosshatch pattern. This is crucial because the crosshatch creates peaks and valleys where the oil gets trapped inside the valleys to lubricate the pistons and piston rings, and the peaks aid in seating the rings to prevent oil consumption and smoking. If you didn’t have a crosshatch pattern you’d burn oil, according to Eric. Bennett’s charges $100 to hone the cylinders. For boring and honing, it costs $200.

Follow along as Eric Bennett demonstrates the step-by-step process of how to properly hone a cylinder. If you missed last month’s installment, log on to hotbikeweb.com for the full article.

Sources

Andrews Products

(847) 759-0190 | andrewsproducts.com

Bennett’s Performance

(562) 498-1819 | bennettsperformanceinc.com

Branch-O’Keefe

(562) 597-2850 | branchokeefe.com

Cometic

(800) 752-9850 | cometic.com

JIMS

(805) 482-6913 | jimsusa.com