Victory Performance Hop-Up

Victory’s 2015 Magnum already came stock with the 106ci Freedom V-twin powerplant that cranks out an impressive 106 pound-feet of torque. It’s easily one of Victory’s boldest models to hit the streets to date, but with some help from Lloyd’z Motor Workz and ProCharger we made it better. See, our pal Lloyd has designed and fabricated this supercharger kit we are installing from the ground up to fit around ProCharger’s B1 blower.

Follow along as Lloyd, Josh Baird, and Kyle Crandall of Lloyd’z Motor Workz get this here Victory Magnum some serious forced induction.

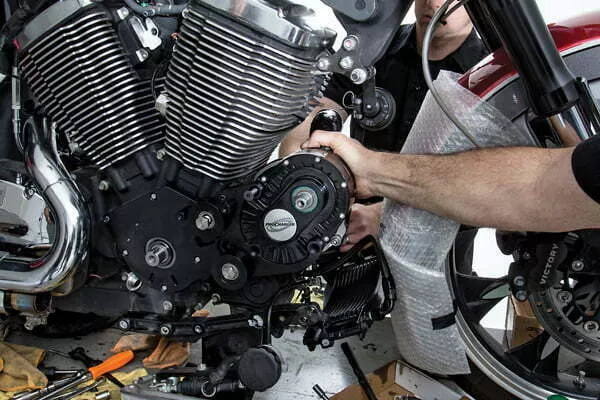

Lloyd started the ProCharger kit install by first bolting up the mounting bracket.

Photos: Wes Drelleshak & Jordan Mastagni

To get a better idea of the difference in parts of the Lloyd’z ProCharger kit, the guys compared the stock fuel line on the right (which enters from the right side) with the Lloyd’z SuperCharger fuel line on the left (which will now enter from the left).

Photos: Wes Drelleshak & Jordan Mastagni

Next, the fellas installed the new fuel line and hi-flow injectors.

Photos: Wes Drelleshak & Jordan Mastagni

Kyle installed the Power Commander V and routed the electrical harness in a neat fashion out of the way of any contact parts.

Photos: Wes Drelleshak & Jordan Mastagni

RELATED | MORE TECH

Then 8.8mm Accel wires and the stock coil were ready for installation.

Photos: Wes Drelleshak & Jordan Mastagni

With the wiring routed, Kyle then raised the frame and started to position the Lloyd’z manifold, throttle body, and intercooler/plenum all in one shot. Lloyd’z has spent countless hours in the design of this setup alone. There is absolutely no room in this area, and it was paramount that no frame modifications be made to make this kit fit. Lloyd’z engineer/machinist Russ Falkena endured many sleepless nights designing a way to get all the pieces to fit and work together without utilizing even one bolt to hold everything together to the motor. The ingenuity and precision here may easily go overlooked unless you carefully study the area. The stock rubber manifold was replaced by two high-temp nylon cones that sit on the head ports, and a specially designed billet aluminum manifold mates to these cones forming a perfectly crush fit seal when the frame member is lowered and tightened in place. When locked down, the assembly sits so securely not even the Hulk could budge it.

Photos: Wes Drelleshak & Jordan Mastagni

Here’s how the right side of the assembly looked when installed.

Photos: Wes Drelleshak & Jordan Mastagni

Now, it was time to reinstall the gas tank.

Photos: Wes Drelleshak & Jordan Mastagni

In stock form, the PVC hose was then vented into the airbox with the addition of a blower specially designed oil catch was put inline to avoid pushing oil up and out of the PVC hose.

Photos: Wes Drelleshak & Jordan Mastagni

The final bolt was then placed in the supercharger mount plate.

Photos: Wes Drelleshak & Jordan Mastagni

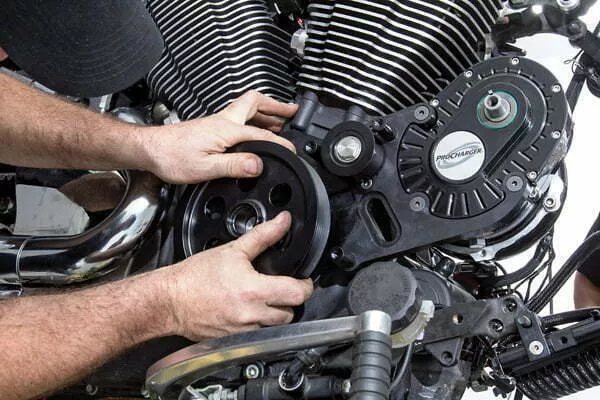

Next, the crank pulley was attached.

Photos: Wes Drelleshak & Jordan Mastagni

This kit was designed with tight tolerances so the pulley was gently tapped into position.

Photos: Wes Drelleshak & Jordan Mastagni

A custom stainless steel front pipe, which was designed to fit tight to all the components, was then slipped into place.

Photos: Wes Drelleshak & Jordan Mastagni

The next step included final fitment and tightening of all bolts.

Photos: Wes Drelleshak & Jordan Mastagni

The installation of the battery in the left saddlebag was then tackled. It was then time to install the elbow and surge valve that sends compressed air from the blower unit to the intercooler.

Photos: Wes Drelleshak & Jordan Mastagni

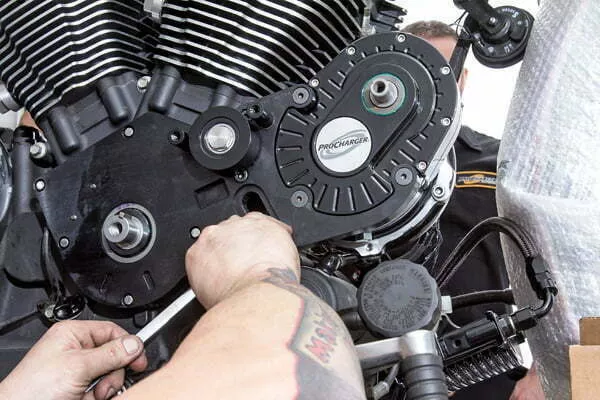

Next, the small pulley and keyway for the supercharger were installed.

Photos: Wes Drelleshak & Jordan Mastagni

After the battery wiring was complete, Josh then reattached the left saddlebag.

Photos: Wes Drelleshak & Jordan Mastagni

Kyle then took the liberty of installing the air cleaner on the supercharger filter tube.

Photos: Wes Drelleshak & Jordan Mastagni

The installation team was steadily making progress as a finely oiled machine. Here, Lloyd installed the belt and tensioner pulley on the right side.

Photos: Wes Drelleshak & Jordan Mastagni

The crew stopped and took a collective breather while giving the supercharger one last look before the belt cover was bolted on.

Photos: Wes Drelleshak & Jordan Mastagni

They say a photo is worth a thousand words, but we actually lost track of everything everyone said during the moment when Lloyd began sizing up the belt cover. Supercharged, check. Lloyd’z official stamp of Victory performance supremacy, check. This picture says it all.

Photos: Wes Drelleshak & Jordan Mastagni

A couple more turns of the wrench, and the belt cover was secured into its final position.

Photos: Wes Drelleshak & Jordan Mastagni

Kyle then mounted the curved oil cooler to the front of the floorboard mounts.

Photos: Wes Drelleshak & Jordan Mastagni

The right floorboard assembly was then secured and tightened.

Photos: Wes Drelleshak & Jordan Mastagni

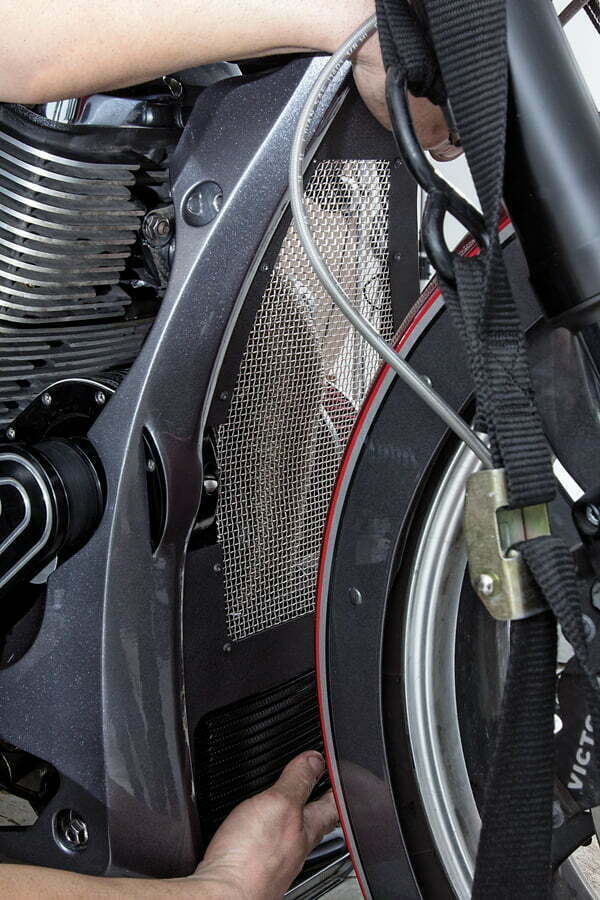

Next, the right-side cowl was put into position. These are stock cowls that Lloyd’z modifies in-house to fit around the supercharger unit.

Photos: Wes Drelleshak & Jordan Mastagni

Here’s a last look of the center screen assembly being installed. The Lloyd’z team has gone to great lengths to ensure this entire kit looks as though it was supposed to be there. Lloyd comments, “People walk by our bikes with these kits installed and they don’t even know the supercharger is there. That’s when we know that we’ve succeeded.”

Photos: Wes Drelleshak & Jordan Mastagni

Just like that, the right side of the assembly was completely buttoned up. Even the shape of the belt cover had to flow with the existing brake lever as to not give away any indication that something awesome is lurking behind it.

Photos: Wes Drelleshak & Jordan Mastagni

Kyle looks on after the kit is fully installed and ready to hit the dyno. Even with an intercooler sticking out, the left side visually flows just as smoothly as the right. When it comes to creating a motor that has a soul of its own and a heartbeat you can feel, it’s no wonder how Lloyd’z has managed to set the bar so high.

Photos: Wes Drelleshak & Jordan Mastagni

When it was all said and done and the dust had settled, the Magnum reached a max horsepower reading of 166.32 and a 146.93 foot-pound torque rating.

Sources