Custom Works Zon’s HRCS Show Winning Shovelhead

Aluminum isn’t new. Neither are Shovelheads. Taking an old Shovel powerplant and cradling it in an aluminum frame, though, that’s a pretty big deal. It’s also the story of what was once a ’73 Harley FLH, and what is now an extremely beautiful Shovelhead custom centered around an aluminum frame. Built by Custom Works Zon, it’s the shop’s 20th anniversary gift to itself and the world of custom motorcycles.

Way back in 2003, Custom Works Zon was opened in Shiga, Japan by Yuichi Yoshizawa. Over the next couple of decades, the shop proceeded to knock down a series of custom show victories, starting with the 2007 Rat’s Hole Custom Bike Show. In 2015, the shop was selected as one of the top five builders in Japan by Harley-Davidson, and won the Street Build Off competition for customizations based on the XG750. Come 2018, the BMW Motorrad head office requested a customization using a prototype engine, and Custom Works Zon won Japan’s Mooneyes Hot Rod Custom Show that year. Four years later, they won it again, this time with this aluminum frame Shovelhead. “I wanted to do a custom that no one had ever tried, symbolizing the 20th anniversary of Zon,” Yuichi Yoshizawa tells us. “I decided to take on the challenge of the aluminum frame because no one had tried it.”

Obviously, this bike didn’t leave the factory with an aluminum chassis back in 1973. The shop bought the FLH used, kept the engine and transmission, and set the rest aside. Coincidentally, ’73 happens to be bike owner Teruhiko Imaizumi’s birth year, so there’s that, too.

The frame is made from Japanese 7N01 aluminum, which is strong enough to be used in airplanes. If you were to throw a leg over this beauty and take it out on the road, the chassis would probably handle whatever stresses you threw at it. Shaping the aluminum tubing into a motorcycle frame, however, was far from easy. That’s probably where Yuichi Yoshizawa figured out why he’d never seen one before: “When I bent the aluminum pipe secondary, it cracked and distorted, and I had to redo it many times. When I first started building the frame, it was a simpler frame than it is now, but I added more pipes in consideration of strength, and carefully made reinforcements at the joints between the pipes. We also paid particular attention to the tail section, which doubles as an oil tank.”

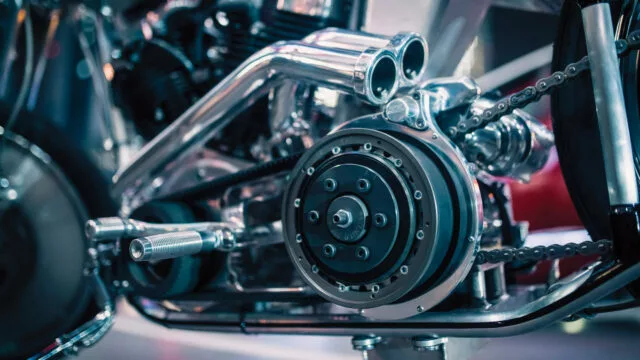

The frame houses a ’73 Shovelhead mill that’s had a few upgrades along the way. Zon bored it out to 93ci; not an extreme displacement in the age of 114-inch stockers but a lot more than the old Shovel had when it rolled off the factory line way back when. They also brought S&S cases, a Weber carb, and a Morris dual magneto setup into the mix. And, as you’d expect, the shop built an exhaust that flows perfectly with the lines of the bike. In this case, accentuating the BDL belt drive on the primary side and giving you an obstructed view of the engraved powerplant on what would usually be the pipe side of the motorcycle.

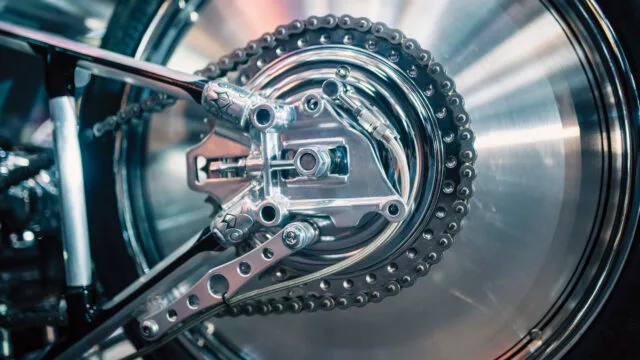

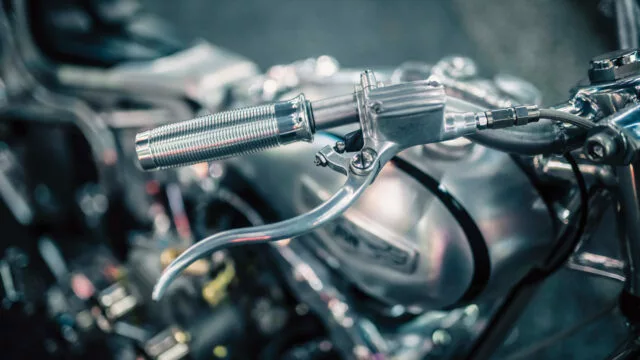

On the handling side, suspension duty falls entirely on a set of 29-inch girder-style front forks. No rear shocks were harmed in the making of this motorcycle. When you’ve gone through all the effort it took to get the aluminum frame built right, hiding it in any way would be almost criminal. The wheels weren’t as involved as the frame but they got their fair share of fabrication work, too. The shop covered their spokes in metal for the solid look (which works damn well on this bike). Shod in skinny Firestone rubber, they rely on Kustom Tech brake systems for stopping power.

Solid wheels are something I’m used to seeing on Harley’s meaty Fat Boy but here, the solids serve to contrast and balance out the smallish gas tank and minimal tailsection instead of complementing a large tank and inverted frontend like they do on the Fatty.

Now, you’d think that a motorcycle shop commemorating its 20th birthday might go hog wild in the paint department. In this case, though, not so much. If your focus is on ambitious fabrication with tons of details and cleanliness, flashy bright paint may not be the best way to finish off your bike. That’s probably why Custom Works Zon let the metalwork speak for itself by eschewing colorization. Instead, they used strategically placed engraving and pinstriping, and bare metal to tell the story.

If the first two decades culminated in this masterwork of the bike builder’s craft, we can’t wait to see what the future holds. As Yuichi Yoshizawa puts it, “From now on, I would like to always look ahead and take on new challenges. As the Coronavirus is coming to an end, I would like everyone overseas to see my custom this year. I have a lot of things I want to do. I would like to do a custom with a Henderson airplane engine, a very old Japanese Kyokutou engine, and a Matsuda CT1200 V-engine.” And hopefully you’ll get to see some of these customs in this here magazine.