Feuling Cam, Oil Pump & Camchest Upgrade

The folks at Feuling have been in the cam business awhile, and when we called our pal Luke there to discuss cams for our internally stock 2015 103ci H-D Twin Cam engine, he was kind enough to offer up some solid advice as well as a whole mess of parts to make our cam swap a much more worthwhile endeavor. Here is what we went with.

Words and Photos: Jeff Leighton

After intake and exhaust, camshafts are usually the next performance upgrade for Harleys. They’re inexpensive, make toque and horsepower, and are pretty easy to install. The task of deciding which ones to use can be a daunting one. There are all sorts of sizes and needs when going with bigger or different cams. Here’s how Feuling helped us out.

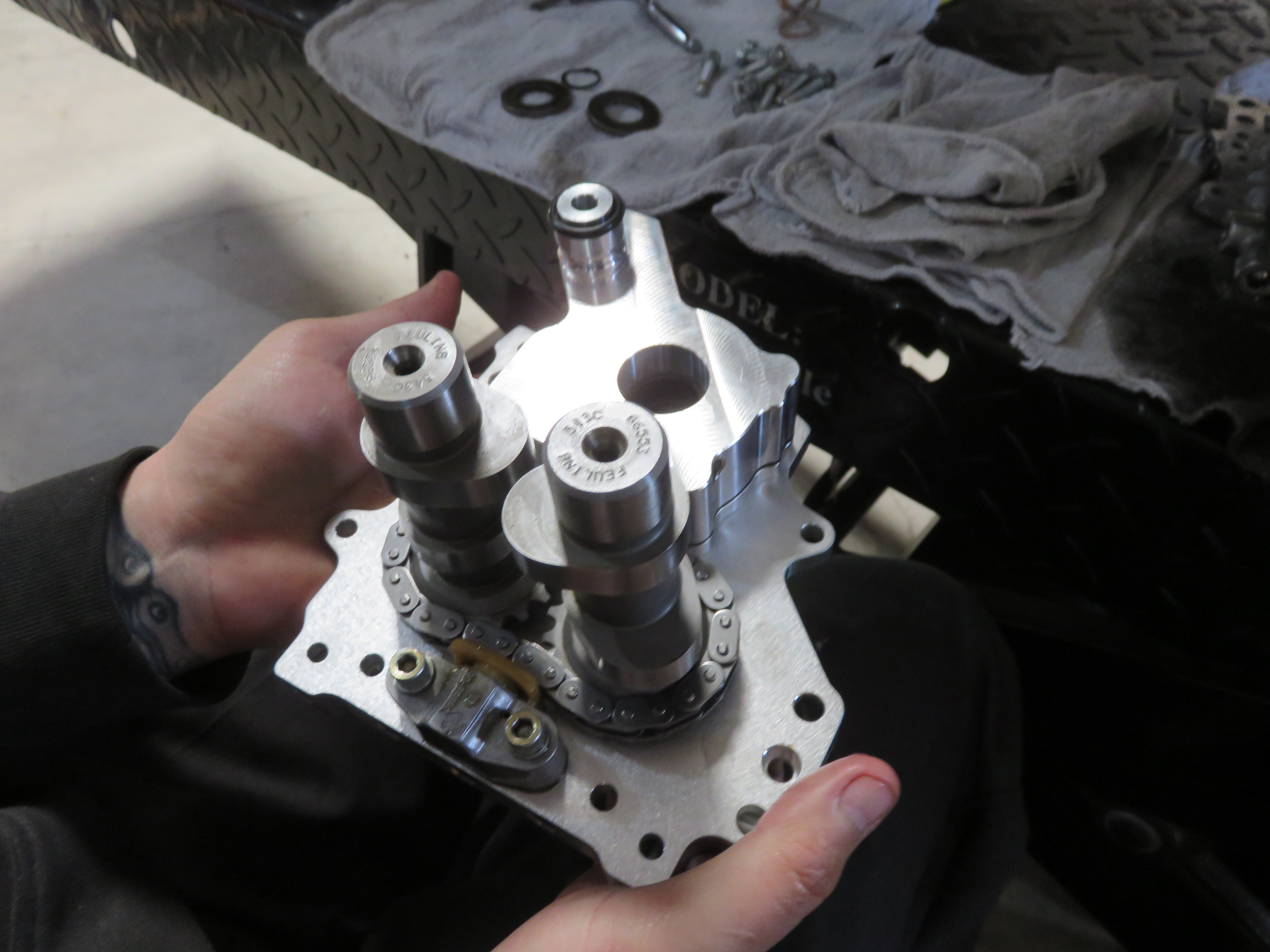

Feuling 543 Reaper Cams ($329) were our choice for bolt-in camshafts for the 103-inch Twin Cam motor we had. This grind of chain-driven cam gives more top-end power but doesn’t sacrifice low-end torque. The 543 cams are easy starting, increase throttle response, and Feuling said it could even give us better fuel mileage. Luke also said that it responds well to a performance exhaust and high-flow air cleaner, which we already had.

Words and Photos: Jeff Leighton

Feuling HP+ Lifters ($159) are performance hydraulic roller lifters that allow more oil flow to the top-end valves, springs, rockers, shafts, and valve guides.

Words and Photos: Jeff Leighton

RELATED | MORE FEULING PARTS

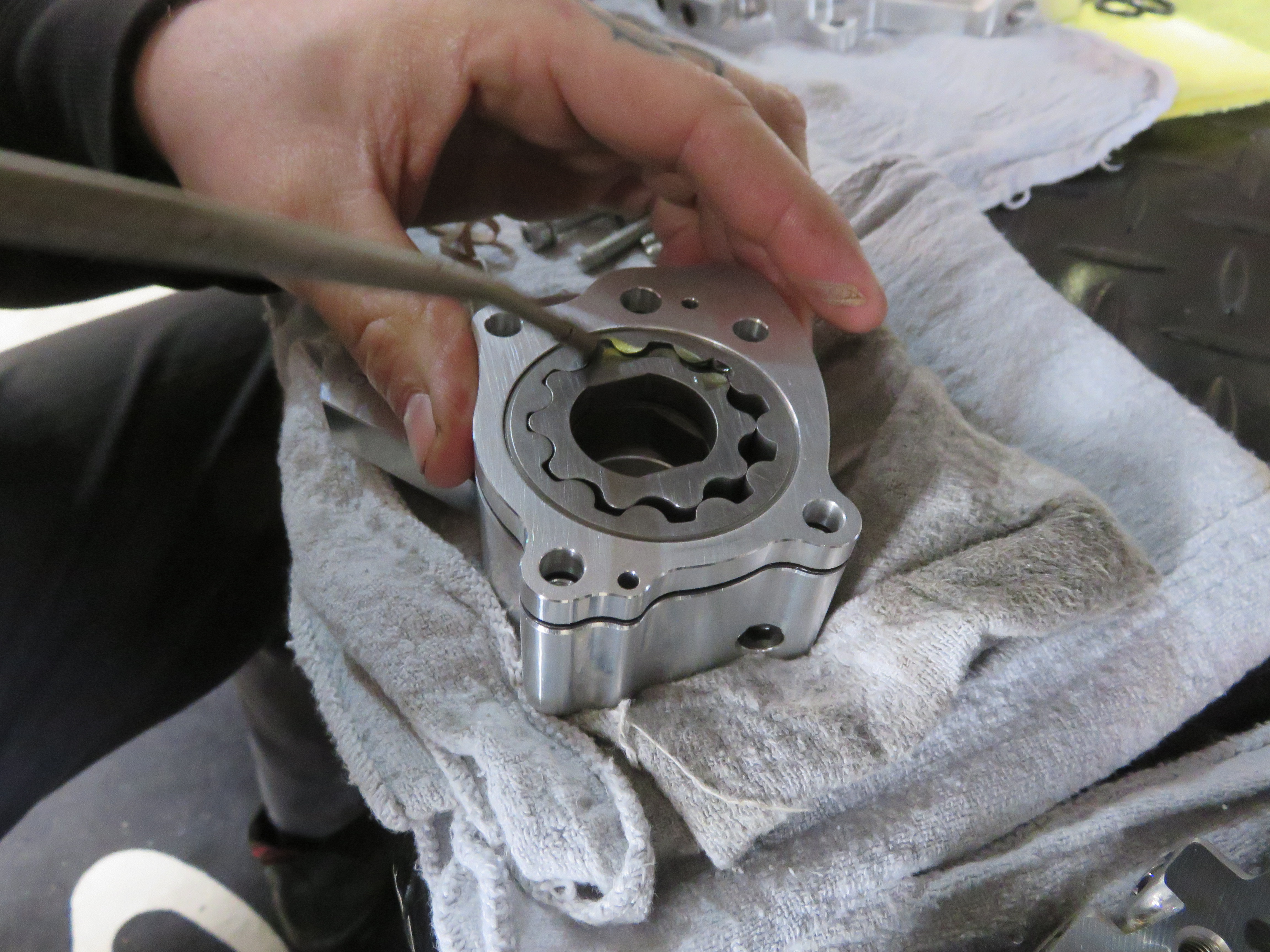

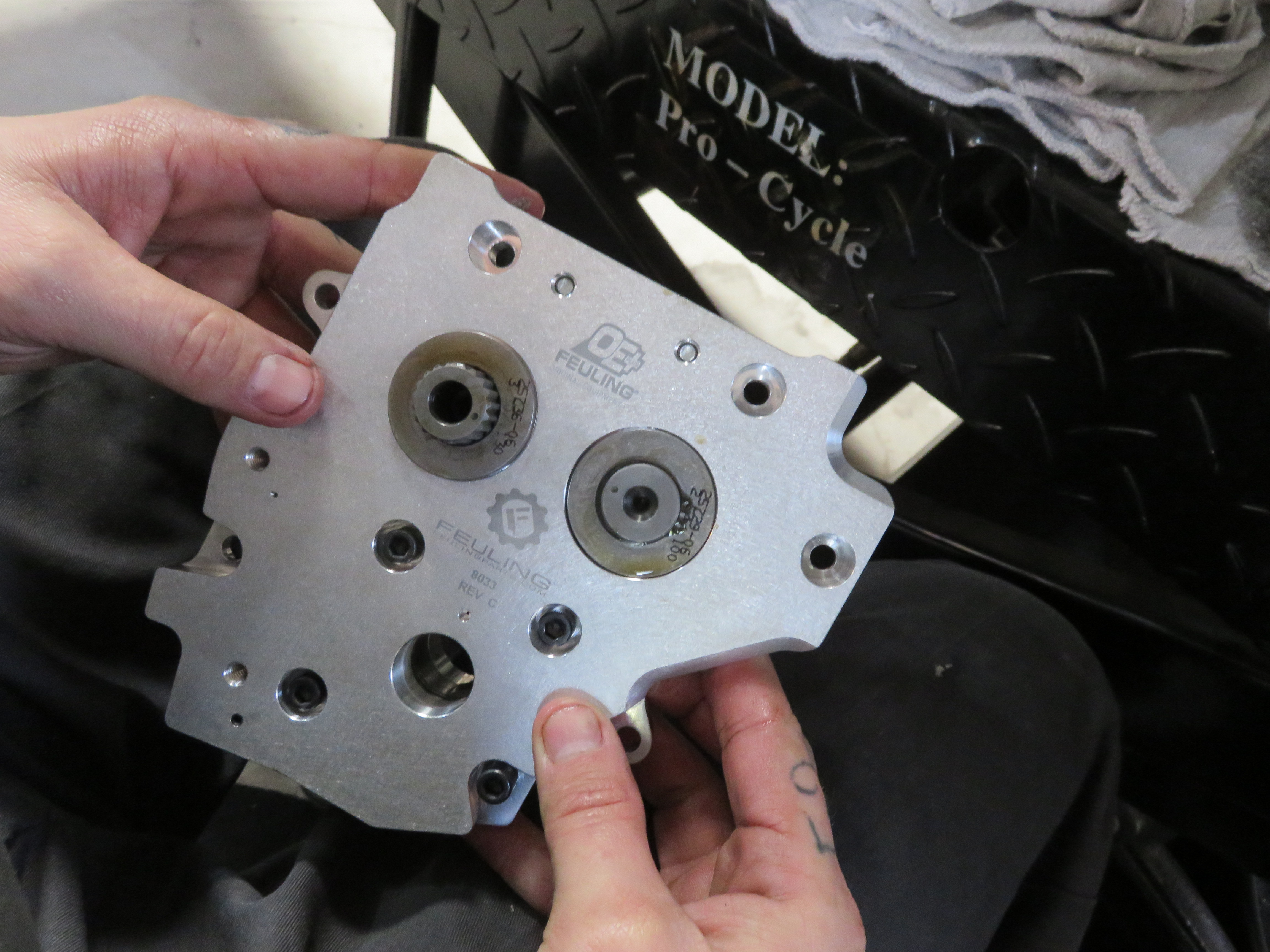

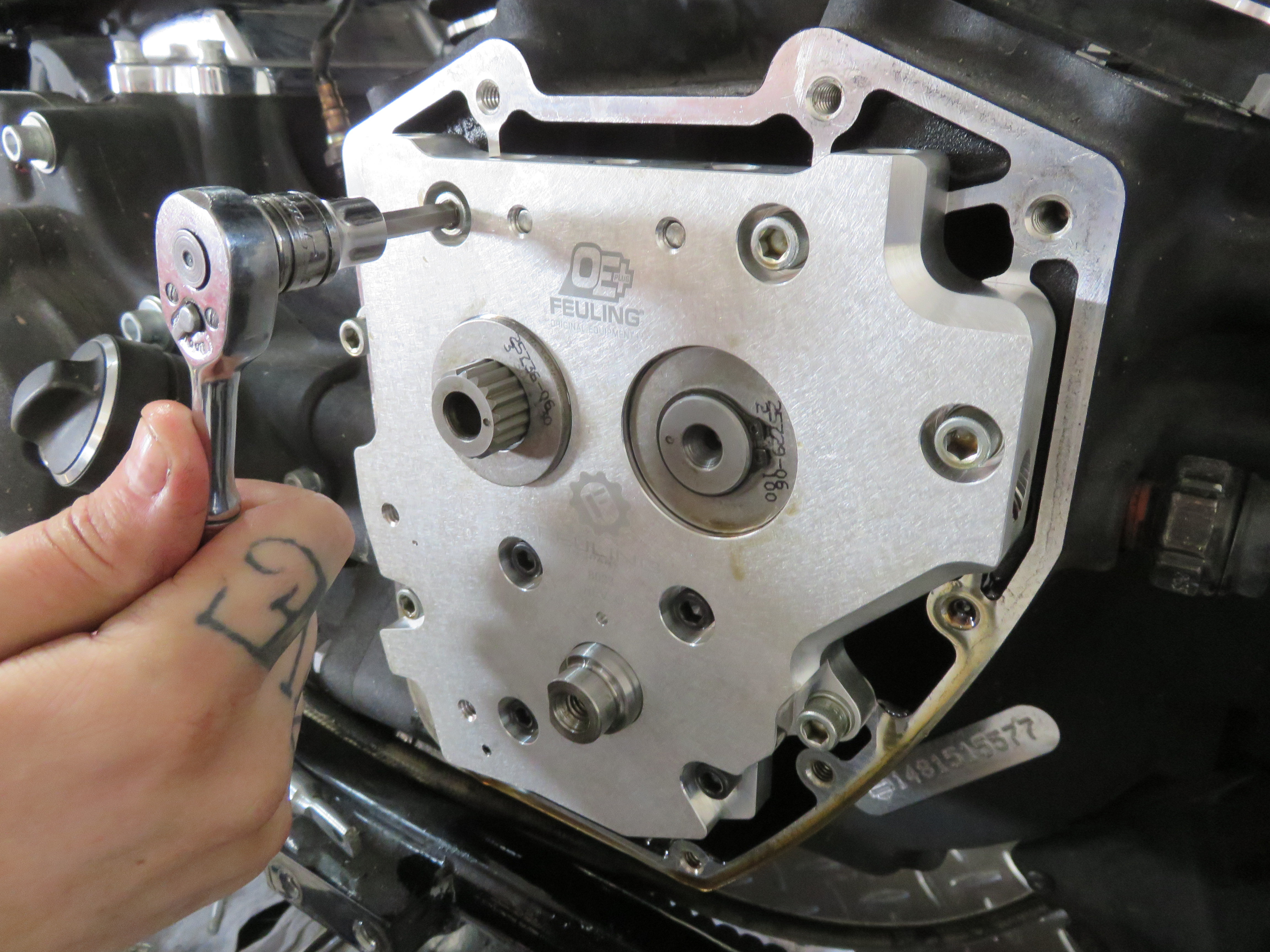

Feuling OE+ Oil Pump and Camplate Kit ($480) upgrades the stock oiling system, delivering increased oil pressure and a better return oil scavenging. The OE+ billet camplates have increased rigidity and are machined to tighter tolerances compared to stock and assemble without O-rings on the pump housings. The OE+ Oil Pump is made from Billet 6061 aluminum with two chrome-moly gerotor gears. It also has 10-percent more pressure volume and 16-percent more scavenge volume over stock oil pumps.

Words and Photos: Jeff Leighton

Feuling FAST Install adjustable pushrods ($239) feature a dual jam nut locking system as well as a slightly shorter tapered tube and come disassembled, which allows the engine builder to install the pushrods without removing the top rocker box.

Words and Photos: Jeff Leighton

Feuling Camchest Gasket Kit ($30) and Cam Installation Kit ($95) has all the various needed gaskets, such as cam cover, lifter block, exhaust gaskets, camplate, and pushrod tube O-rings. The Quick Change Camshaft installation kits include Timken camplate roller bearings, KOYO Torrington full roller needle inner cam bearings, 12-point ARP camshaft and crankshaft bolts with hardened washers, and camshaft retaining clip to do the job right.

Words and Photos: Jeff Leighton

We start the cam upgrade by taking off the cam cover of the motor and removing the stock cam chain, chain tensioner, and sprockets, which we will be reusing.

Words and Photos: Jeff Leighton

The stock single-piece pushrods will not be reused, so we cut them out as not to have to remove the top end of the motor. This is common practice.

Words and Photos: Jeff Leighton

The stock cam chest and cams were carefully removed from the motor.

Words and Photos: Jeff Leighton

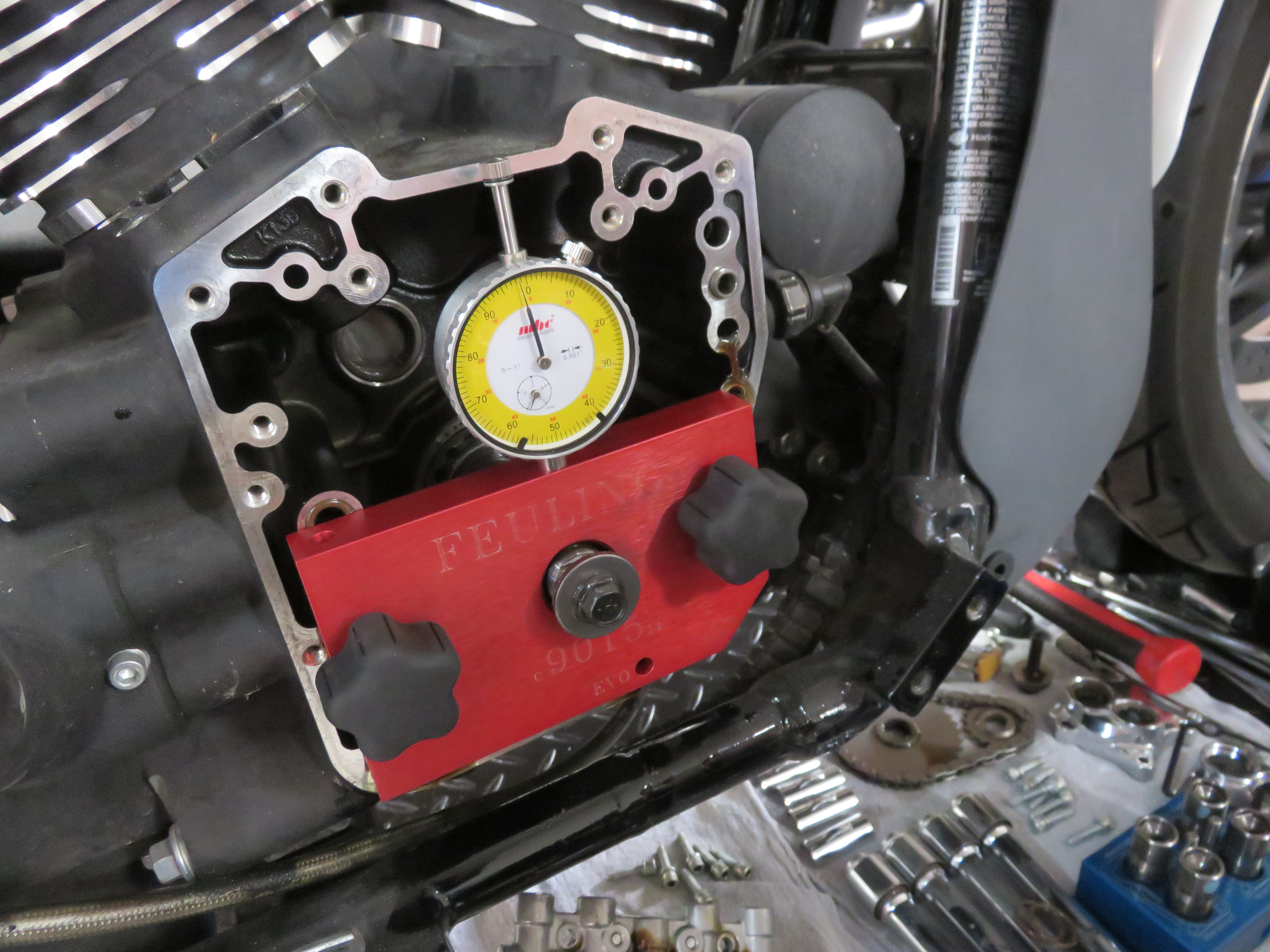

We used our Feuling Crankshaft Runout Measuring tool. This tool measures accurate readings of the engine’s crank pinion shaft runout. Ours was just in the allowed tolerances set by Feuling.

Words and Photos: Jeff Leighton

The stock H-D cam chain and chain tensioner were removed from the OEM cam chest.

Words and Photos: Jeff Leighton

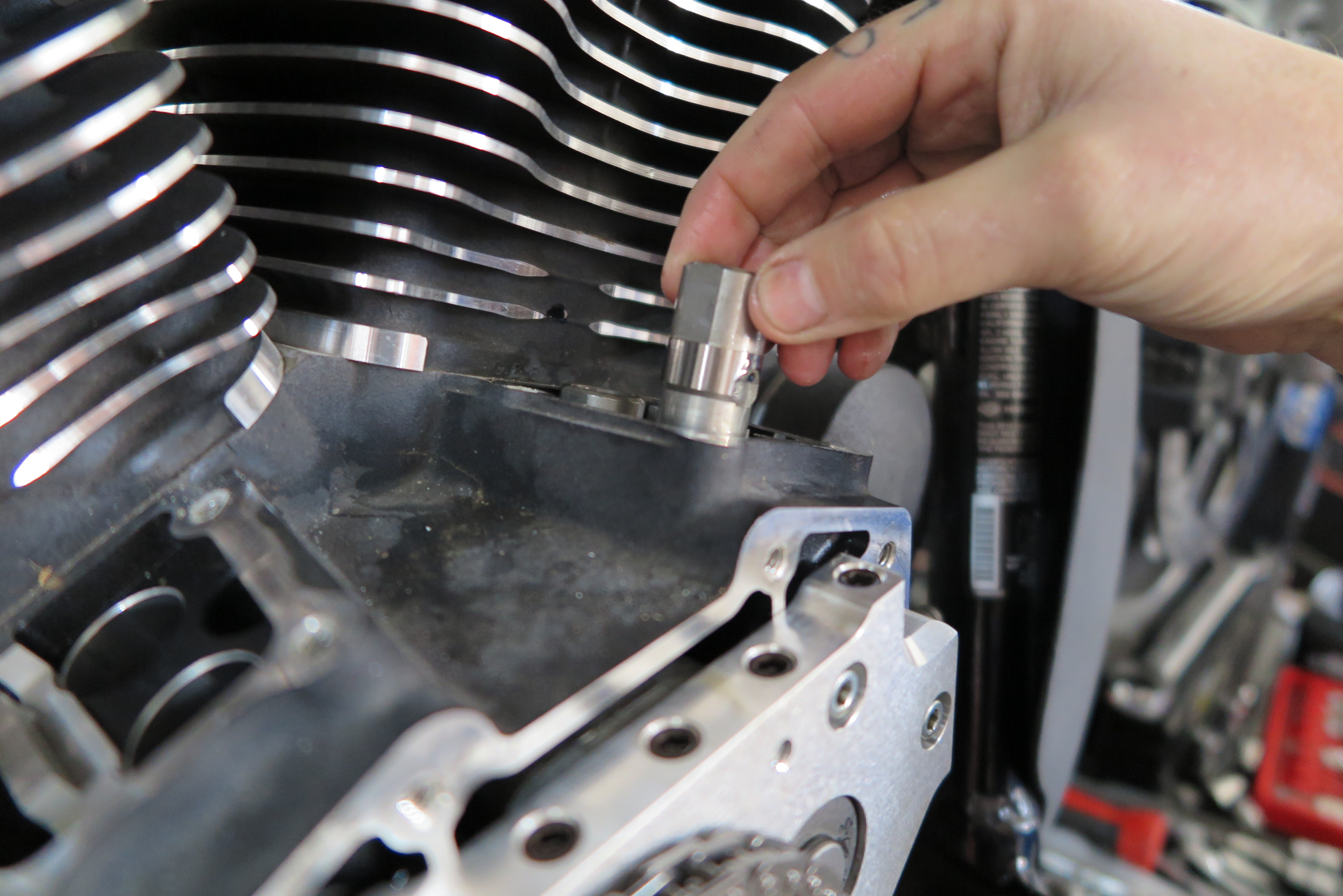

The Feuling Oil Pump was pre-lubed with the correct weight motor oil before it was installed onto the new camplate.

Words and Photos: Jeff Leighton

Jim at IMZZ Elite pulled the old cam bearings from the motor and installed the new ones supplies in the Feuling kit.

Words and Photos: Jeff Leighton

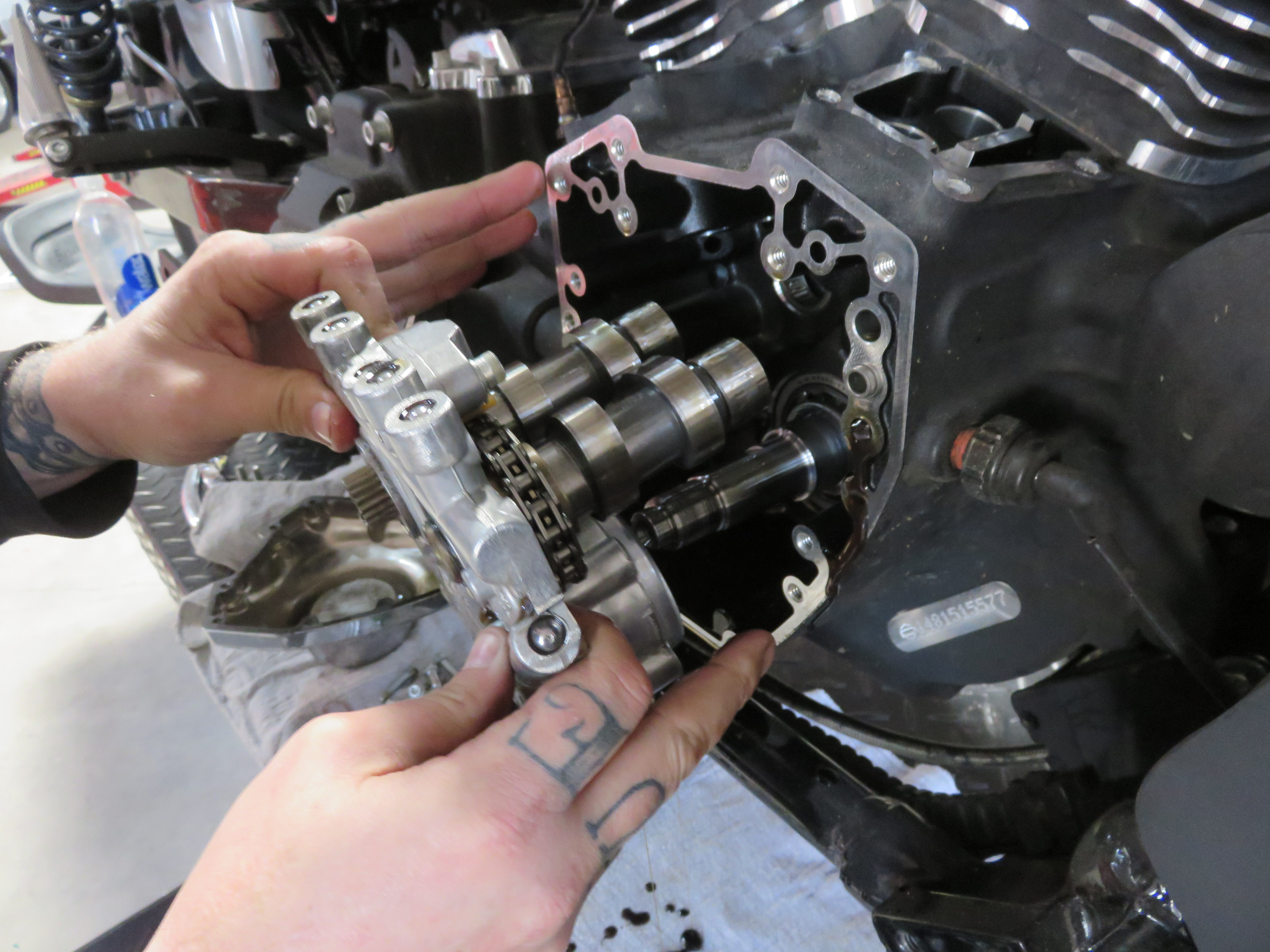

The Feuling cams and oil pump were installed onto the new camplate and torqued to factory specs.

Words and Photos: Jeff Leighton

To properly line up the cams in correct order, the two hash marks on the front of the cams had to be lined up.

Words and Photos: Jeff Leighton

The new camplate, cams, and oil pump were installed into the engine and torqued to factory specs.

Words and Photos: Jeff Leighton

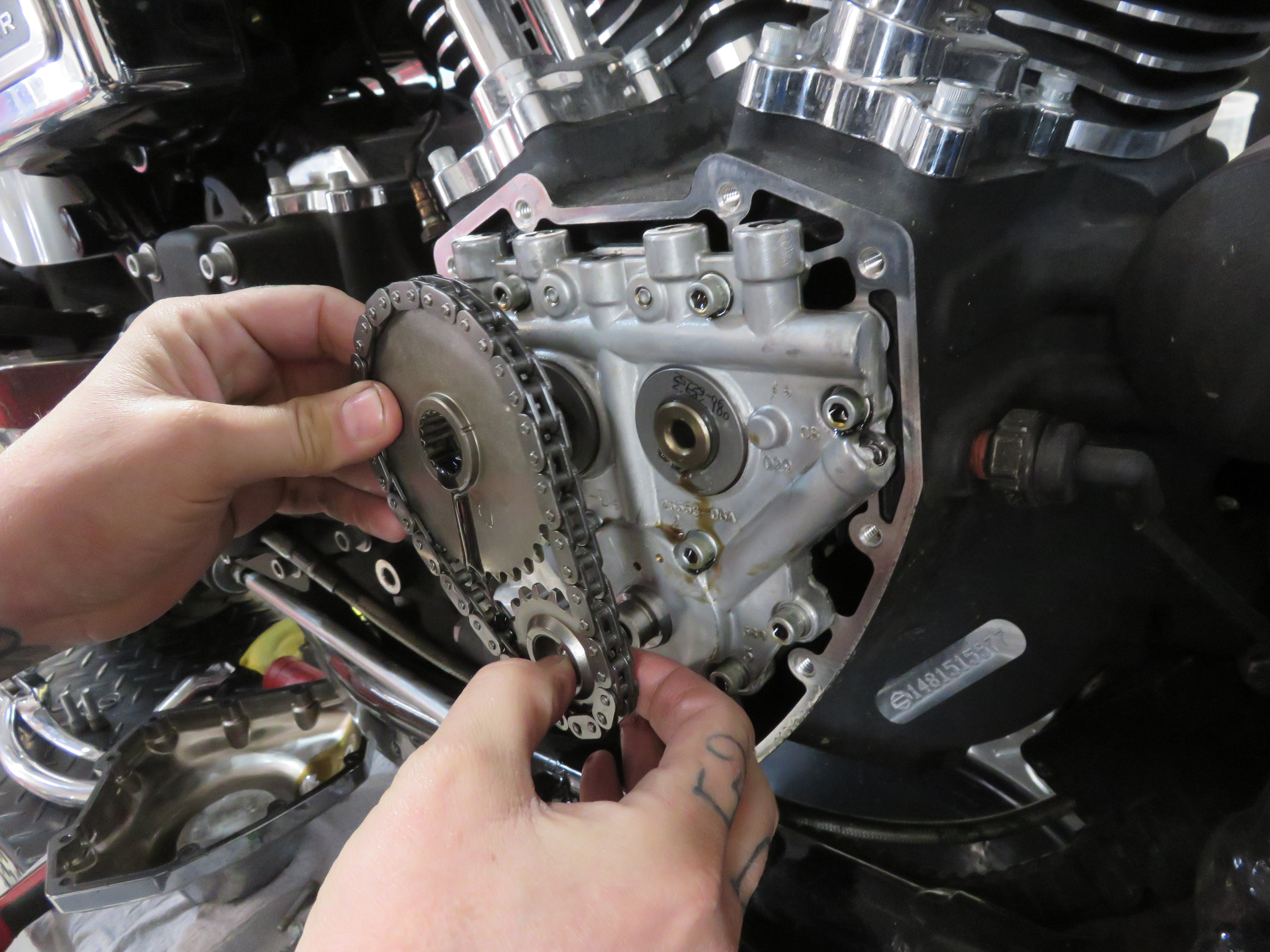

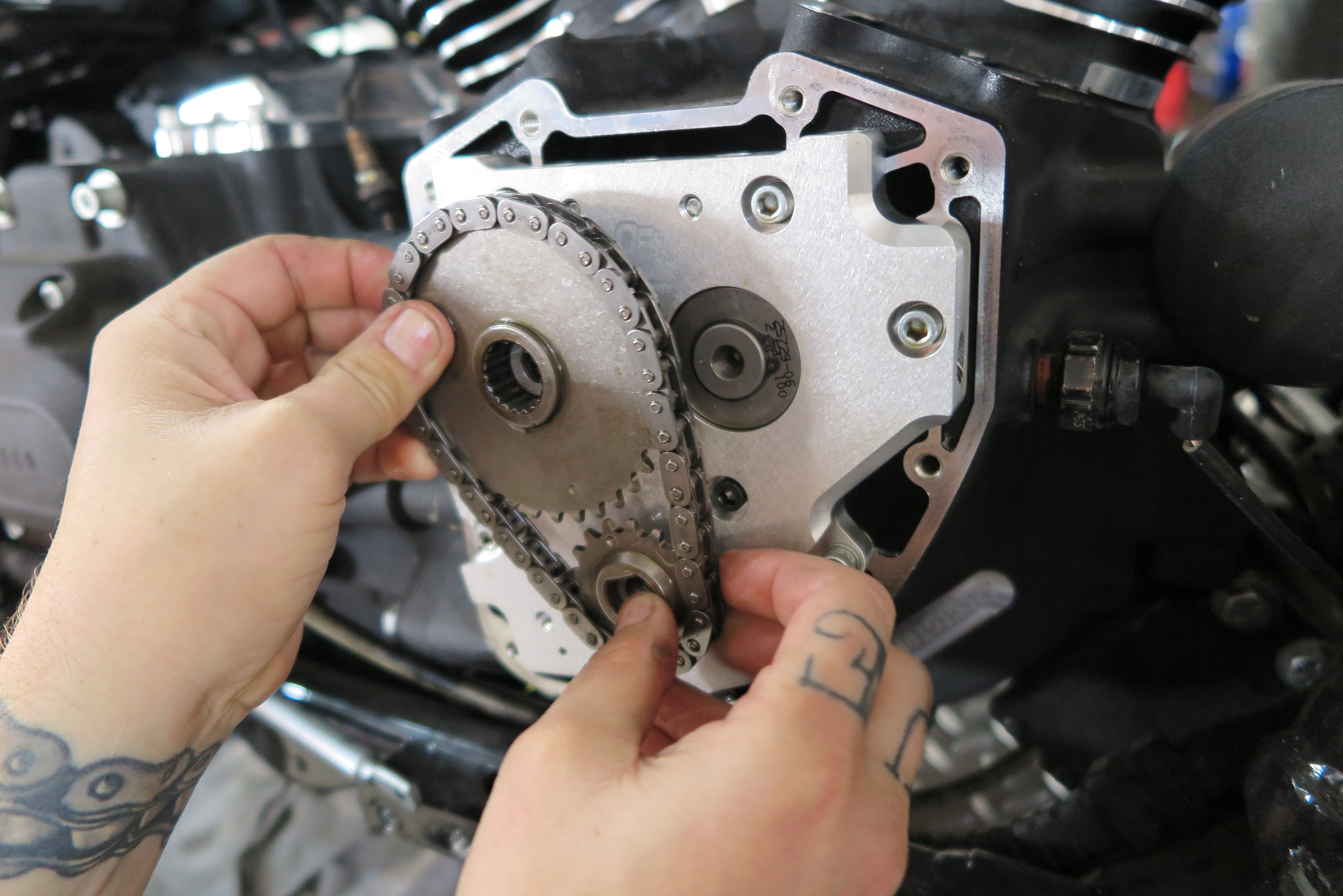

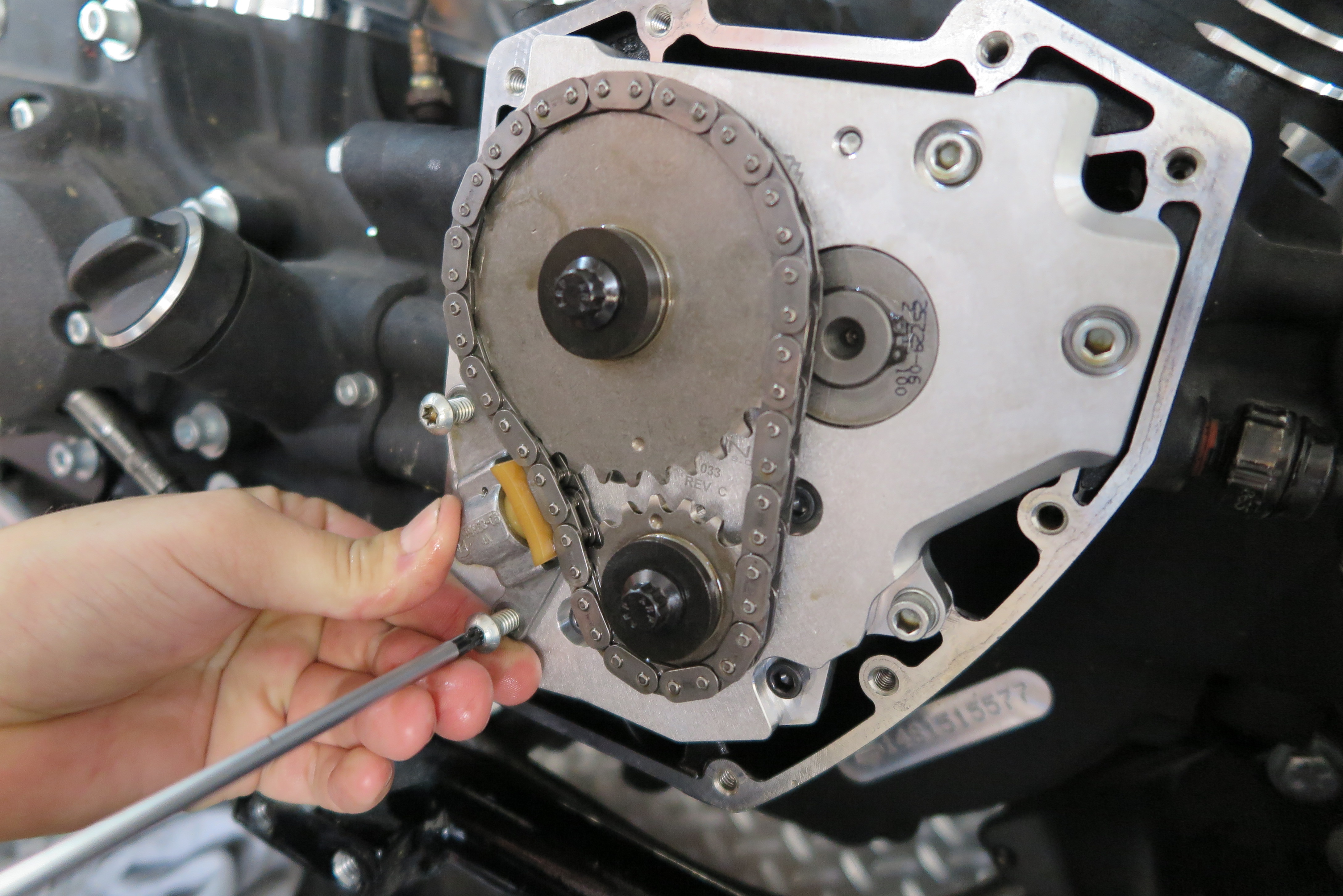

The stock H-D cam sprockets and chain were installed onto the Feuling cams.

Words and Photos: Jeff Leighton

The Feuling-provided ARP bolts now hold the cam sprockets in place, and the cam chain tensioner was properly installed and adjusted as per the H-D service manual.

Words and Photos: Jeff Leighton

The new Feuling HP+ lifters were pre-lubed then placed inside the engine.

Words and Photos: Jeff Leighton

The stock lifter blacks were reinstalled using new Feuling-supplied gaskets.

Words and Photos: Jeff Leighton

The FAST Install adjustable pushrods were installed and adjusted as per the instructions provided by Feuling.

Words and Photos: Jeff Leighton

And once the engine covers, foot controls, and exhaust system were installed we were done with our Feuling cam upgrade. Check out hotbike.com for a video and subsequent dyno run.

Words and Photos: Jeff Leighton

Sources