Harley Davidson 96 Inch Evo Engine Rebuild

Bob began by bolting up a set of torque plates to the Axtell cylinders. He then used a bore gauge to accurately measure the cylinder bore; it measured 3.625 inches at the top, middle, and bottom.

Axtell included a set of JE pistons and gaskets with the cylinders. The pistons came complete with wrist pins, locks, and a full set of rings. Once unpacked, they were measured with a micrometer. They came in at .0035-inch smaller than the bore in the cylinder, exactly what we were looking for.

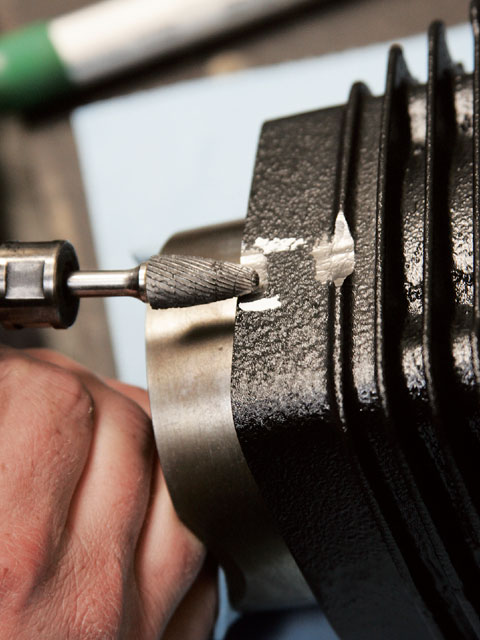

Before proceeding further, Eric placed a Cometic base gasket over the cylinder studs prior to checking the rear cylinder for clearance. There was a bit of interference at the bottom of the cylinder and fin and the lifter block. The affected areas were marked with White Out.

With the cylinder on the bench, a little attention from a die grinder was all that was needed to allow the cylinder to fit squarely on the case. Just a touch of black paint, and the cylinder looked like new.

Eric used a set of KASTAR cylinder hold-down nuts to secure the iron cylinder in place. This allowed him to measure the deck height (dimension from the top of the cylinder to the top of the piston at TDC). He did this with a straightedge and a feeler gauge. The measurement came out to .015 inch; we were looking for .005. We got there by swapping out the .020-inch base gasket for a .010-inch base gasket- simple as that.

Bob then used a feeler gauge to check for proper ring end gap. He likes to have .0045 inch per inch of bore for an iron cylinder. Based on a 3.625-inch bore, we were looking for just over .016 inch of gap for the rings. They measured .018 inch, which should be just fine.

The rings were then gently manipulated to slide into the bottom of the cylinder. Bob inserted them just far enough to be sure the oil-control ring was not showing.

Prior to sliding the cylinder and piston over the cylinder studs, some assembly lube was spread over the piston’s skirt. Bob lowered the components until Eric was able to slide the wristpin through the connecting rod and the piston.

After installing the second cylinder and piston, Eric used a 10-spline ratcheting output wrench to spin the crank, verifying that everything rotated smoothly.

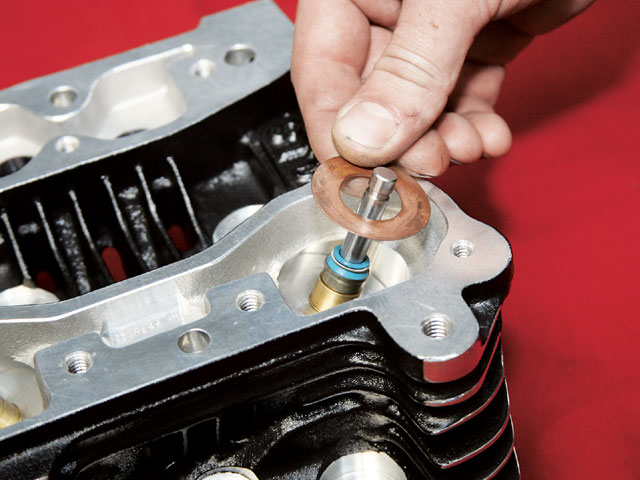

Here, the 1.940-inch intake valve was slipped into place.

Eric then slid the valve-stem seal over the valve stem.

Here is a look at the parts that surround the valve stem.

On a set of stock Harley heads, you won’t find a shim under the lower collar. To ensure tight tolerances and a precise fit, STD includes them with its heads.

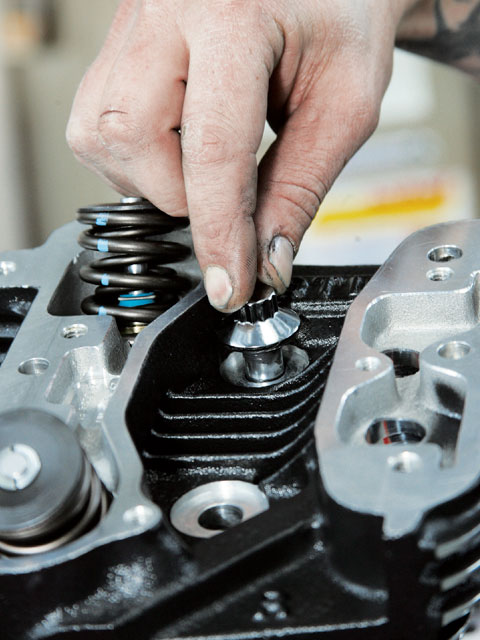

In order to install the valve keepers, Eric placed the head in a valvespring compressor to aid in assembly.

A close look at the compressed spring revealed the relief in the valve stem in which the keepers will sit.

This is what the keepers look like once they’re in place.

Cometic’s three-piece head gaskets are held together with a pair of rivets. Due to the design of the heads, the rivets needed to be removed for clearance purposes.

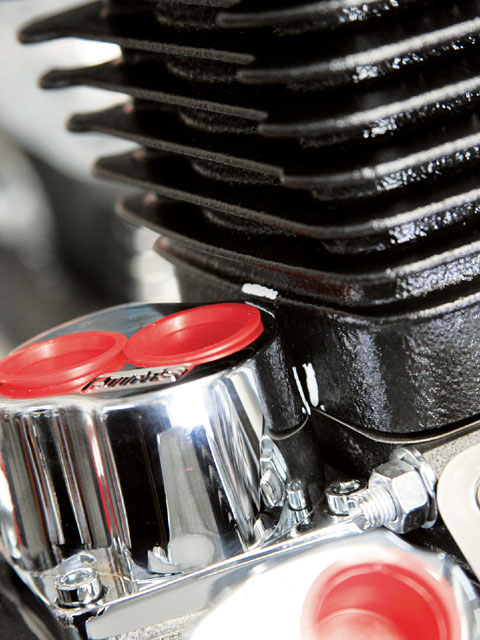

Just to keep everything looking good, we went with a pair of Gardner-Westcott chrome head bolts.

One head on, and one more to go. Note that the rivets have been removed from the Cometic gasket.

Eric torqued the heads by tightening them four times: to 15 lb-ft, 25 lb-ft, 35 lb-ft, and finally 42 lb-ft.

Shipped with the STD heads was this huge S&S; intake manifold. The opening for the carb is 1.800 inches compared to the stock manifold, which is 1.630 inches.

Those of you who are regular readers of HOT BIKE magazine have no doubt been following our 96-inch Evo build. For those of you not familiar with the project, here’s a quick synopsis: Our goal was to build a strong and reliable, streetable motor without the restraints of using components packaged as a kit. Rather, we wanted to pick and choose parts we felt would work well together once combined to help us reach our goal.

To this point we have a complete bottom end consisting of Harley cases, a JIMS stroker flywheel, a TP Smart Pump (oil pump), a Dave Mackie DM 595 cam, and an S&S; reed valve-style breather.

As we planned, we toyed with the idea of using a set of aftermarket cases. After weighing the ups and downs, we decided to stay with the stock Harley cases in order to keep the serial numbers consistent between the engine and the bike. This could prove to be a big plus when dealing with Johnny Law, or for whenever we decide to sell the bike.

This month, Bob and Eric Bennett of Bennett’s Performance in Signal Hill, CA, will be fitting the JE pistons into a set of Axtell cylinders, then topping them off with a pair of STD heads. The cylinders we chose are a set of Axtell cast-iron pieces (part No. 200-028; MSRP: $915 per pair). We decided to go with cast iron versus aluminum because the cast-iron pieces are extremely stable, and will remain straight and true for many years to come. Axtell manufactures the cylinders utilizing a one-piece cast-iron design, unlike an aluminum cylinder, which has a cast-iron sleeve fitted to it during the manufacturing process.

We will be attaching a pair of flat-top JE Pistons (part No. 161947, included with the Axtell cylinder kit) to the JIMS connecting rods. Based on our calculations and the dimensions of our components, the engine will have a compression ratio of 10.6:1. This should allow us to run the bike on premium pump gas without any problems. The final components we will be installing this month will be a pair of STD Stage IV cast-finished heads (part No. 1990; MSRP: $1,678). Features of the heads include STD’s bathtub-design 1.650-inch exhaust, 1.940-inch Kibble White Black Diamond valves, and Crane premium valvesprings. The highly efficient, ported and polished heads are designed to flow 320 cfm at 28 inches of water (different manufacturers rate these figures differently, so for comparison purposes make sure you are talking apples to apples when looking at different heads).

With the oil-control ring in the piston’s bottom ring groove, Bob used a piston-ring installer to place the second ring (with the dot facing up) in the middle groove. The gap in the ring was placed by the back of the exhaust valve. The top ring was then installed with its gap by the intake valve. This is the coolest area of the piston, so placing the gap here should lead to a long life for the ring.

Eric made sure the manifold lined up just right to ensure that a smooth flow of air would pass to the heads. The bolts were gradually tightened to ensure the manifold would seat properly on both heads.