Inside Out | Glenndyne Design’s Internal Brake Wheels

01. Here’s the IB Wheel installed on one of Glenndyne Design’s customized Road Glides.

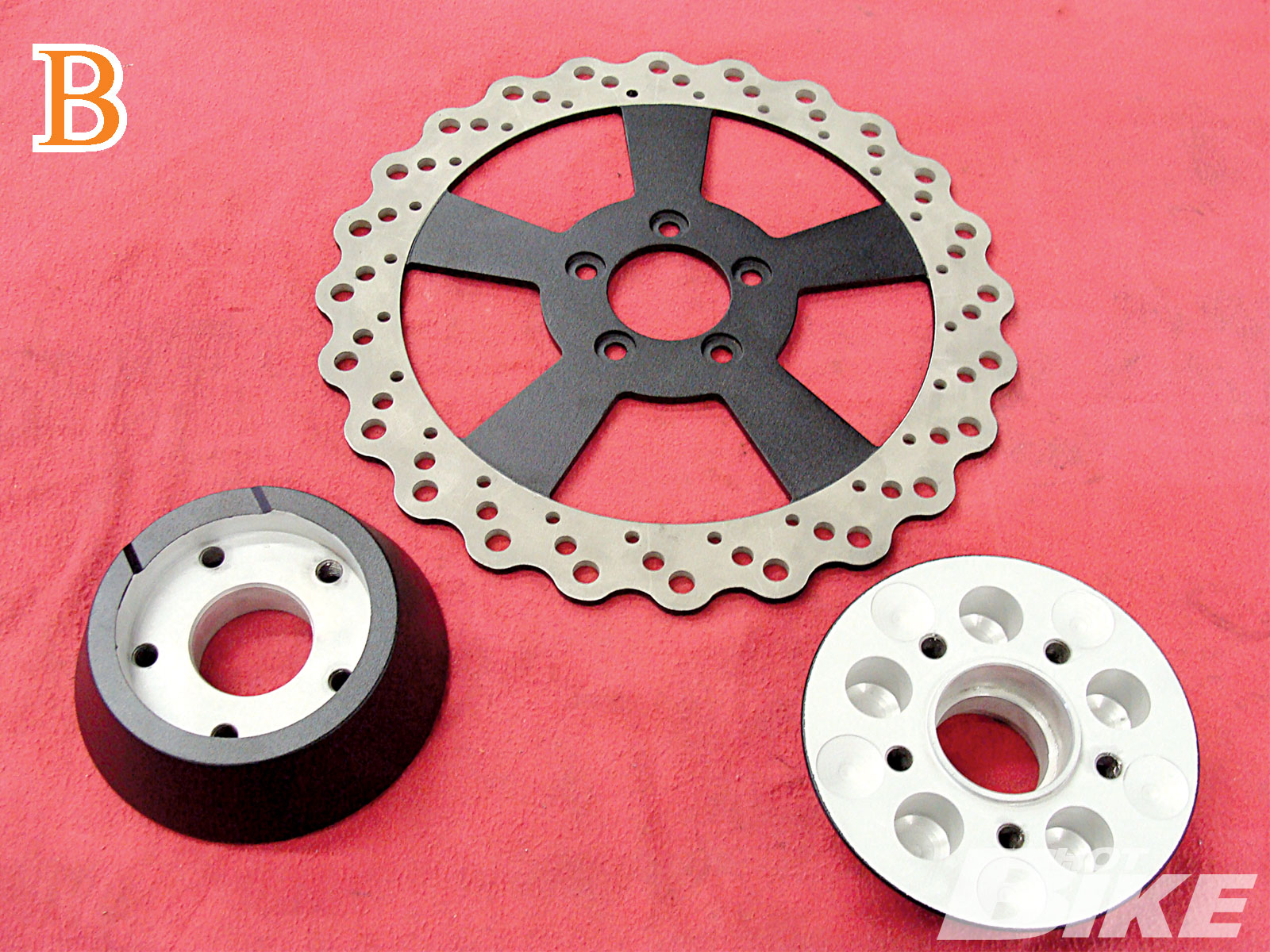

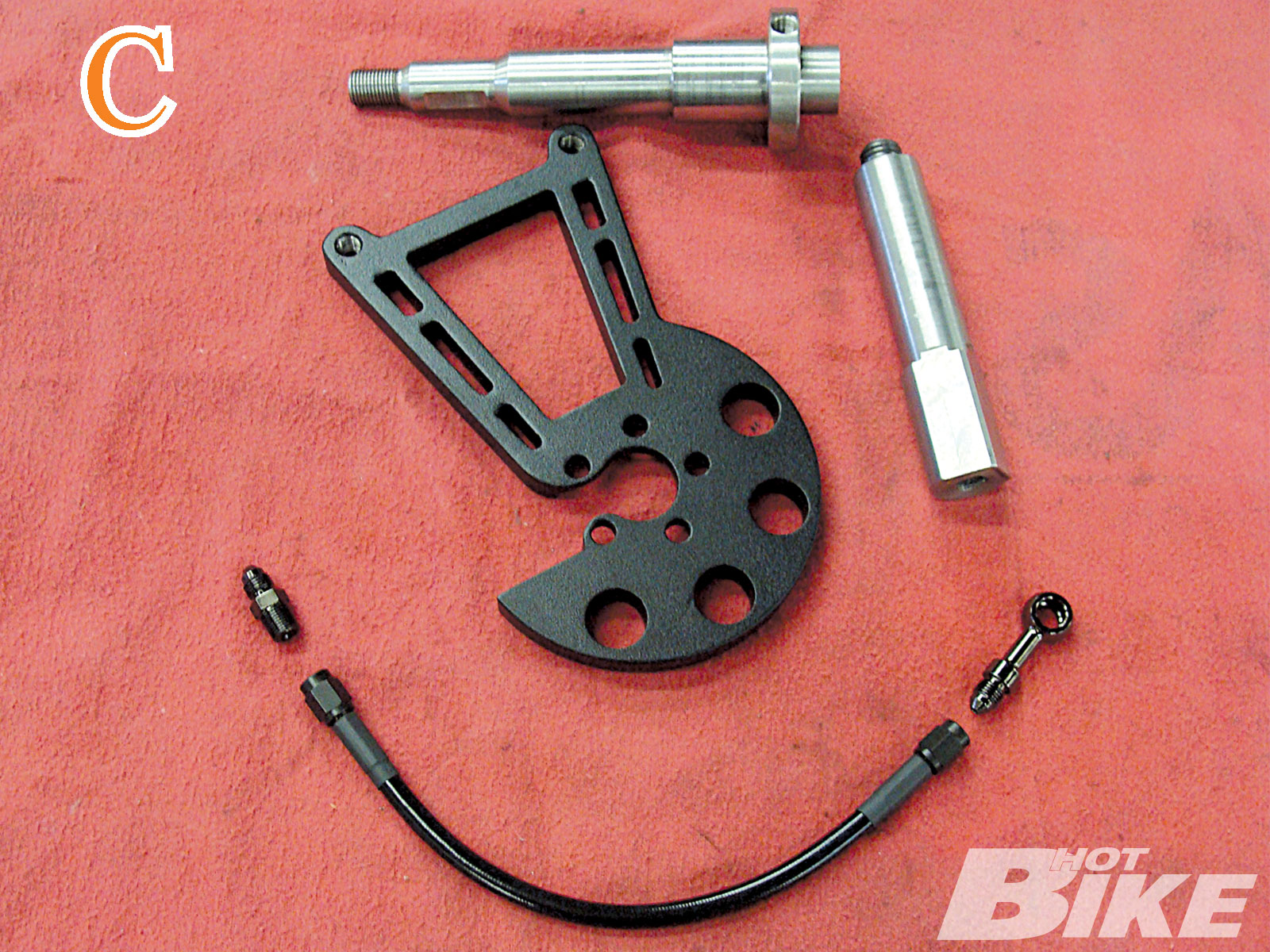

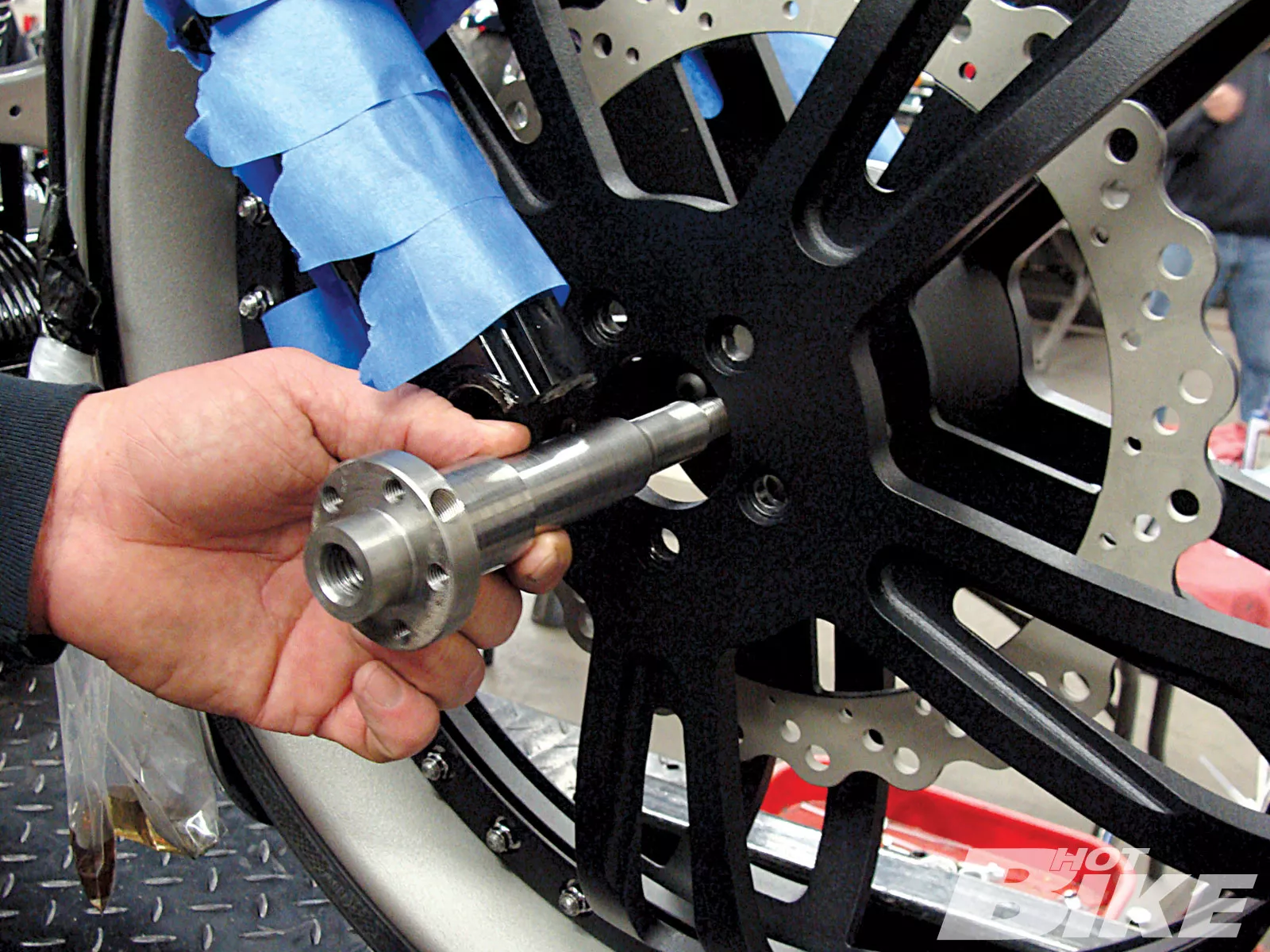

02. The setup consists of two satin black wheel faces (one side shown) (A), the left and right bearing carriers/hubs and rotor (B), a caliper bracket, and brake line for a caliper-to-axle internal flange connection to a two-piece axle (C), and an Avon tire with a solid one-piece rim mounted in place (D).

03. Aaron mounted the first wheel face to the one-piece rim and flipped the wheel over to start the hub and rotor installation.

04. With the wheel flipped over, Aaron installed the bearing hub and rotor and torqued it down to spec.

05. Aaron bolted on the second wheel face and torqued it down. He then made preparations to mount the constructed IB on the frontend of the Road Glide. He’ll have to take the right-side hub off in order to mount the two-piece axle. More on that later.

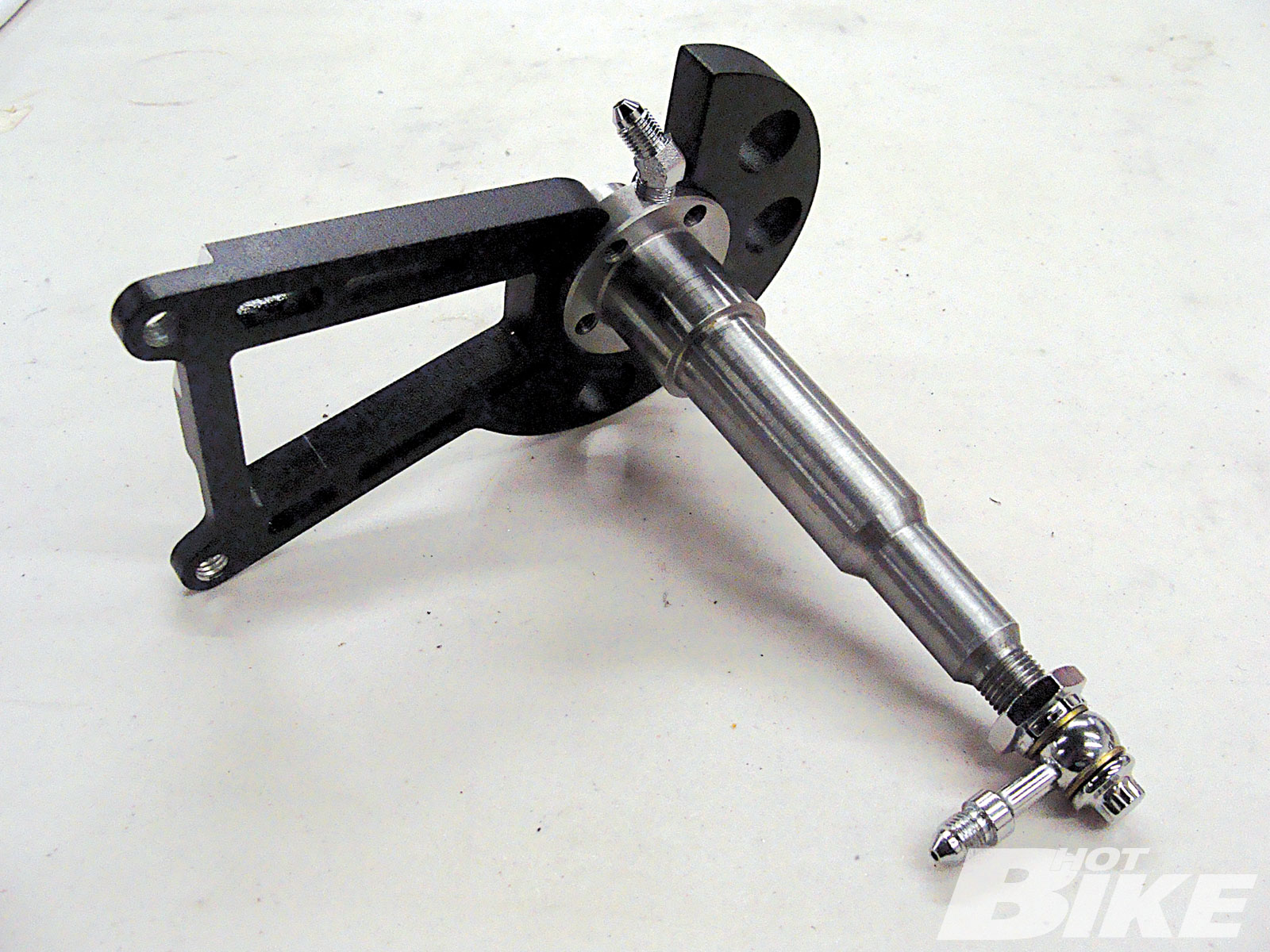

06. Here’s a shot of how the machined axle flange mates with the counter-bored section of the caliper bracket.

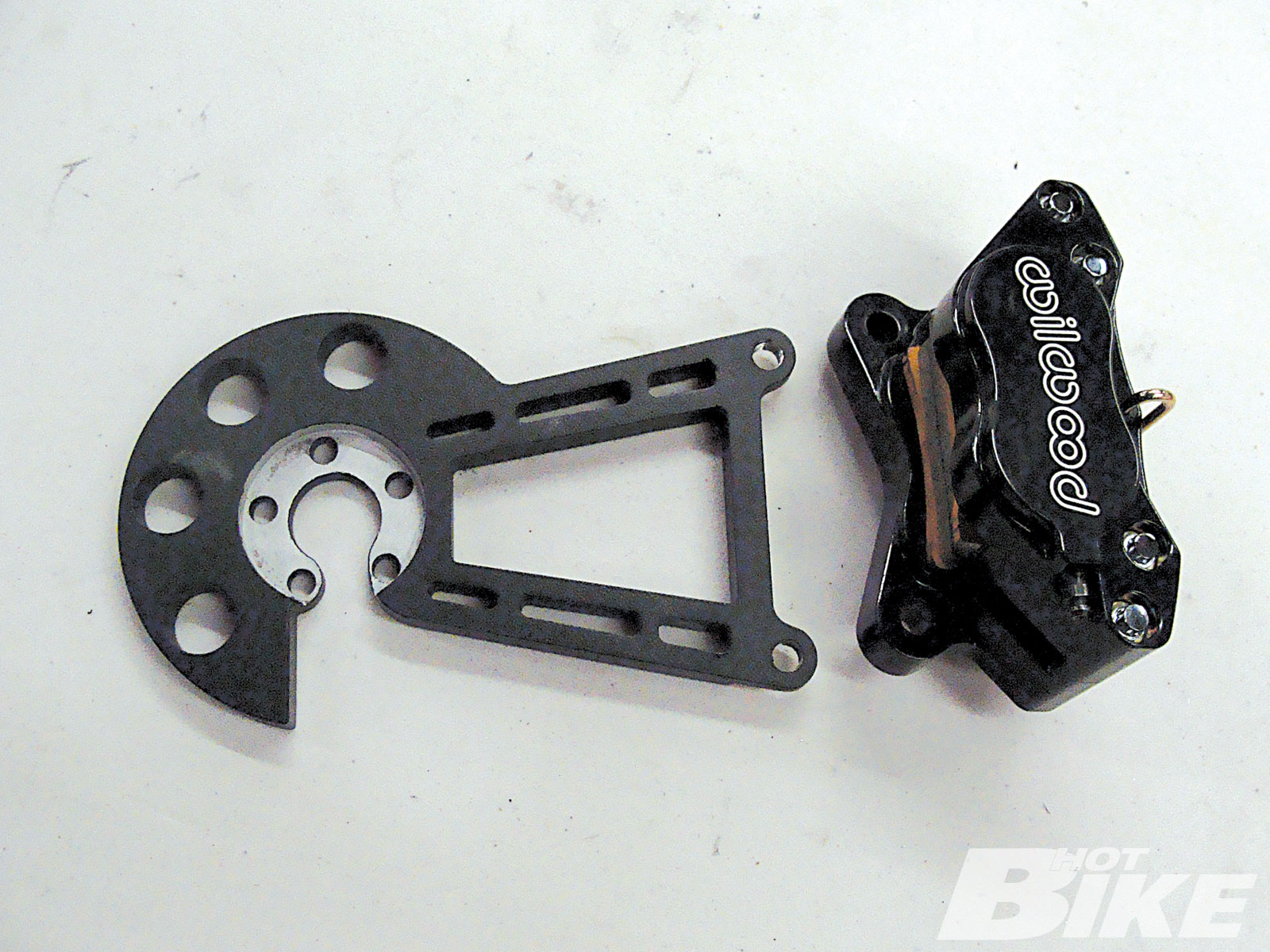

07. Once the caliper bracket is mounted, a Wilwood caliper will be attached to the bracket and brake line, and it’ll be ready to roll.

08. Aaron slid the axle assembly through the right-side wheel face with the right side bearing hub removed (the hub has to be removed after balancing to slide the axle through the opening in the wheel face). The hub is bolted back into place once the first axle section with caliper bracket flange is set and through the left lower leg axle hole.

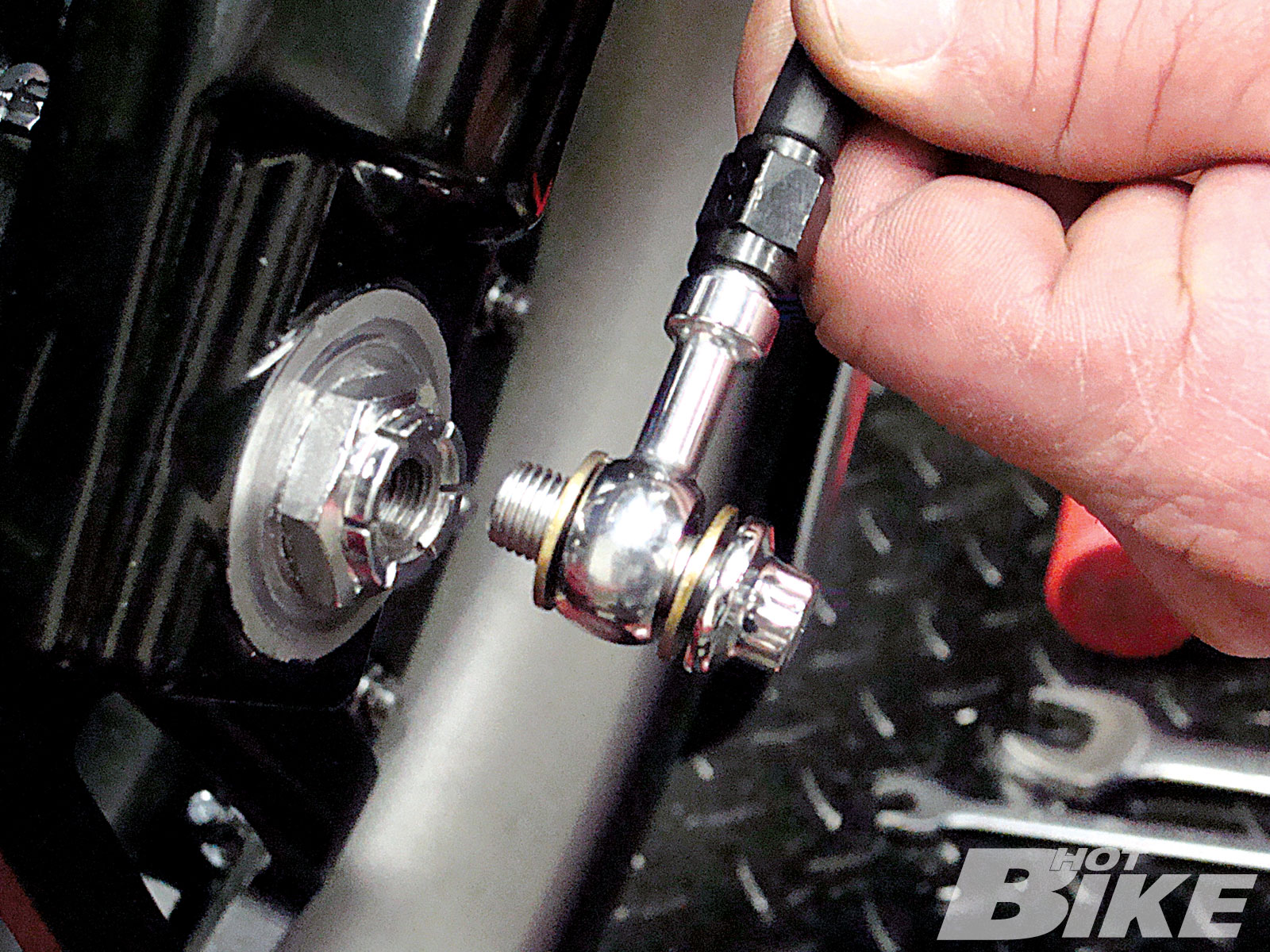

09. After the first part of the axle was slid through the lower leg and through the wheel, the caliper was mounted to the caliper bracket and the brake line was hooked up with a standard banjo, which actually flows fluid to and from the caliper from the master cylinder on the handlebar through the axle to this banjo hooked up on the outside of the second part of the axle that’s now fitted with a standard brake line leading up to the master cylinder. Pretty trick, we know.

10. …to this banjo hooked up on the outside of the secon part of the axle that’s now fitted with a standard brake line leading up to the master cylinder. Pretty trick, we know.

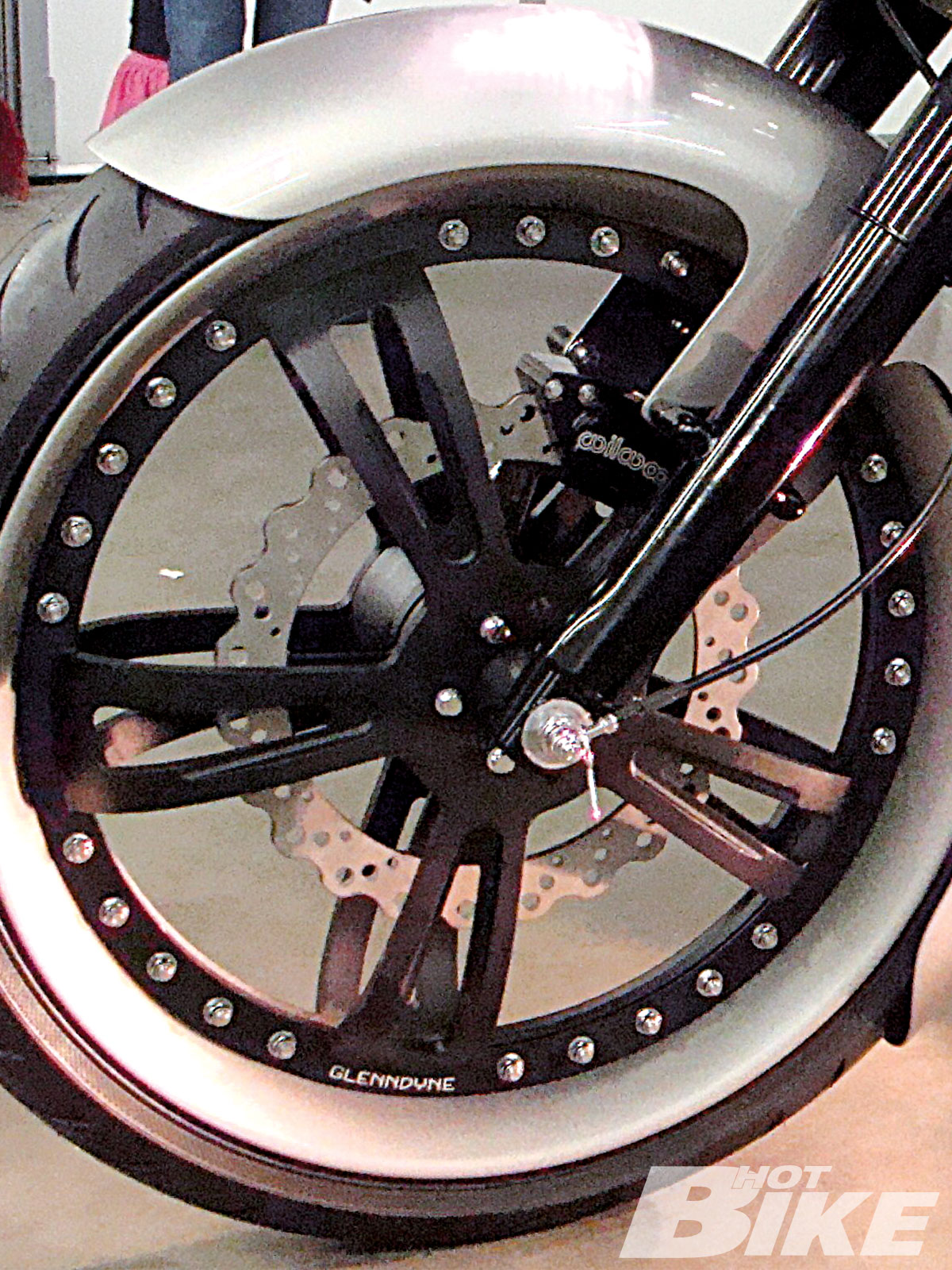

11. Here’s the finished product, the IB wheel installed on Glenndyne’s Road Glide. Look for a full feature in our sister publication, HOT BIKE Baggers, soon.

12. Also, to match the IB Wheel, Glenndyne has designed these solid, cast rear wheels with matching rotors to fit multiple Harley-Davidson models.

In Depth We first laid eyes upon Glenndyne Design’s trick Internal Brake (IB) Wheel aboard a sick, one-off chopper we found at the 2009 Las Vegas BikeFest rally. After leering at the IB setup aboard the custom bike for a while, and chatting it up with owner/designer, Aaron Glenn, and his buddy Skippy, we knew that the product was going to be a hit for Harley customizers everywhere.

A few months later at the V-Twin Expo in Cincinnati, Aaron showed up with the IB setup on a Road Glide. Aaron wanted to show that the setup wasn’t just for custom applications, but could easily be used on a stock bike as well. During the Expo, he gave us the rundown on how the IB Wheel works and how it’s installed. Basically, the IB Wheel is a three-piece forged wheel with two rotary-forged outer wheel faces. There’s a solid one-piece rim that installs into the tire and joins the two wheel faces on both sides via fasteners. According to Glenndyne, its design allows the wheels to be bolted together without the typical sealing issues of multi-piece wheels. The brake components are housed inside (rotor, caliper, brake line, two-piece axle) with the caliper bracket indexed to the axle assembly, which is secured and slotted into the rear adjuster block or lower leg of the frontend. The caliper bracket transfers brake fluid to the brake via the axle assembly with standard DOT fittings. Essentially, the wheel spins around the inside brake setup. The IB Wheel has been awarded multiple patents and is now in full production in a variety of colors and sizes from 16 to 26 inches.

We infiltrated the Glenndyne headquarters in Oklahoma City, to see how the IB works, and is installed.

Sources

Glenndyne Design

(405) 401-8707

glenndynedesign.com