Rolling Along With Ride Wright Wheels

A view from above. Walking around the RWW facility, we saw wheels in various forms from raw rim bands to complete wheels ready to be shipped to customers. Looking down from the second story balcony allowed us to witness the equipment RWW uses to create its wheels; 10 CNC machines—a mix of mills and lathes.

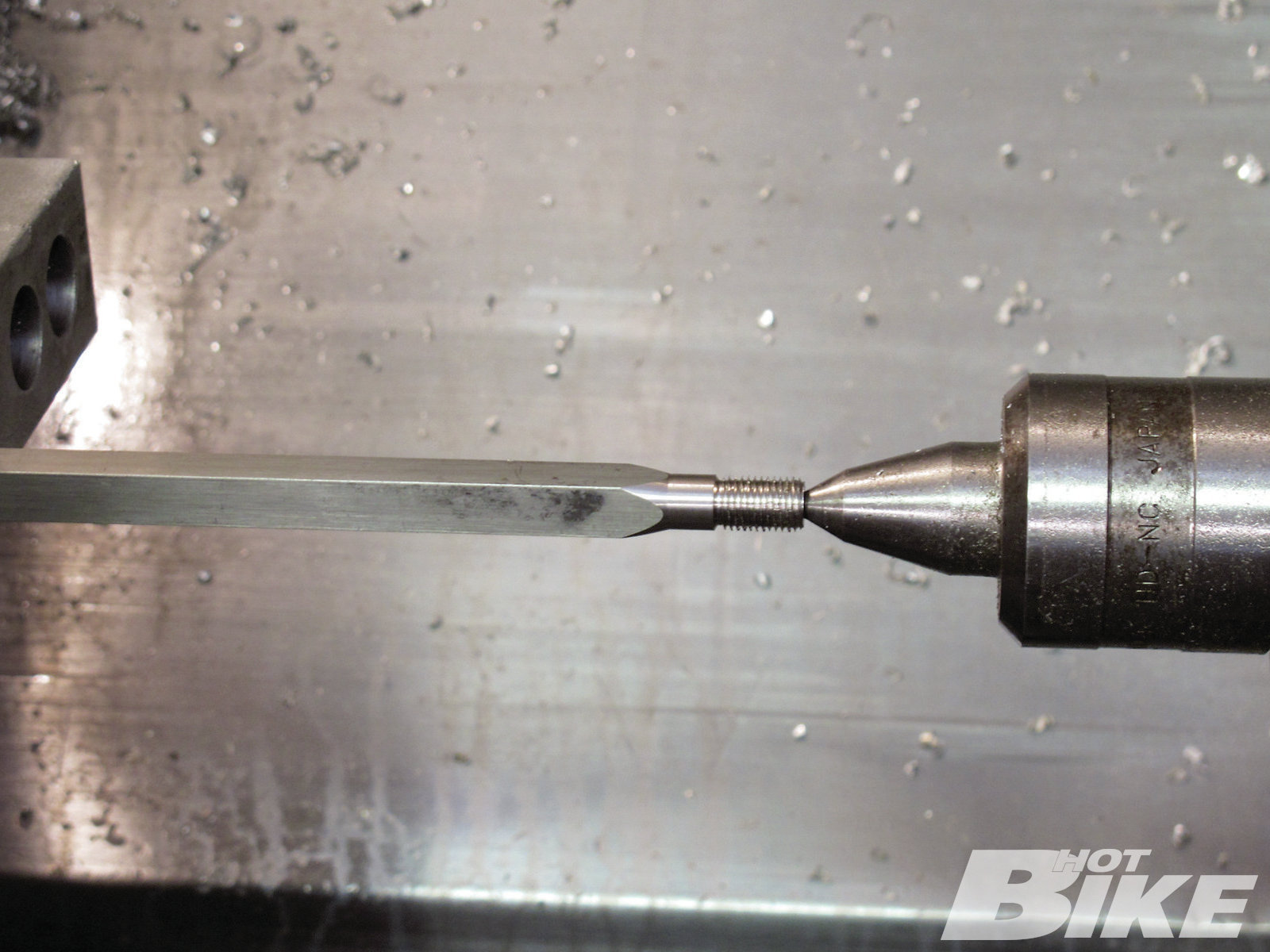

01. Downstairs we ran into Twista spokes being made. Similar to the original Smoothie Fat Daddy spokes, the Twista, Jewel, and Blade fat spokes start out as a piece of 3/8-inch, 304 stainless steel square stock.

02. The raw material is cut to length for each spoke depending on the wheel size; 16-30 inches. Each end is then squared off and the threads are then cut into each end using a CNC lathe.

03. The spoke is then put into a CNC mill and the spoke design is created. As you can see for the Twista design, the mill simply cuts into the 90-degree edges of the square stock to give it mix of machined and squared surfaces for a four-cornered ripple effect. Depending on the length, it takes about 15 minutes to design the spoke. Once the spokes are finished, they are given a high-polish finish to gleam in the sun.

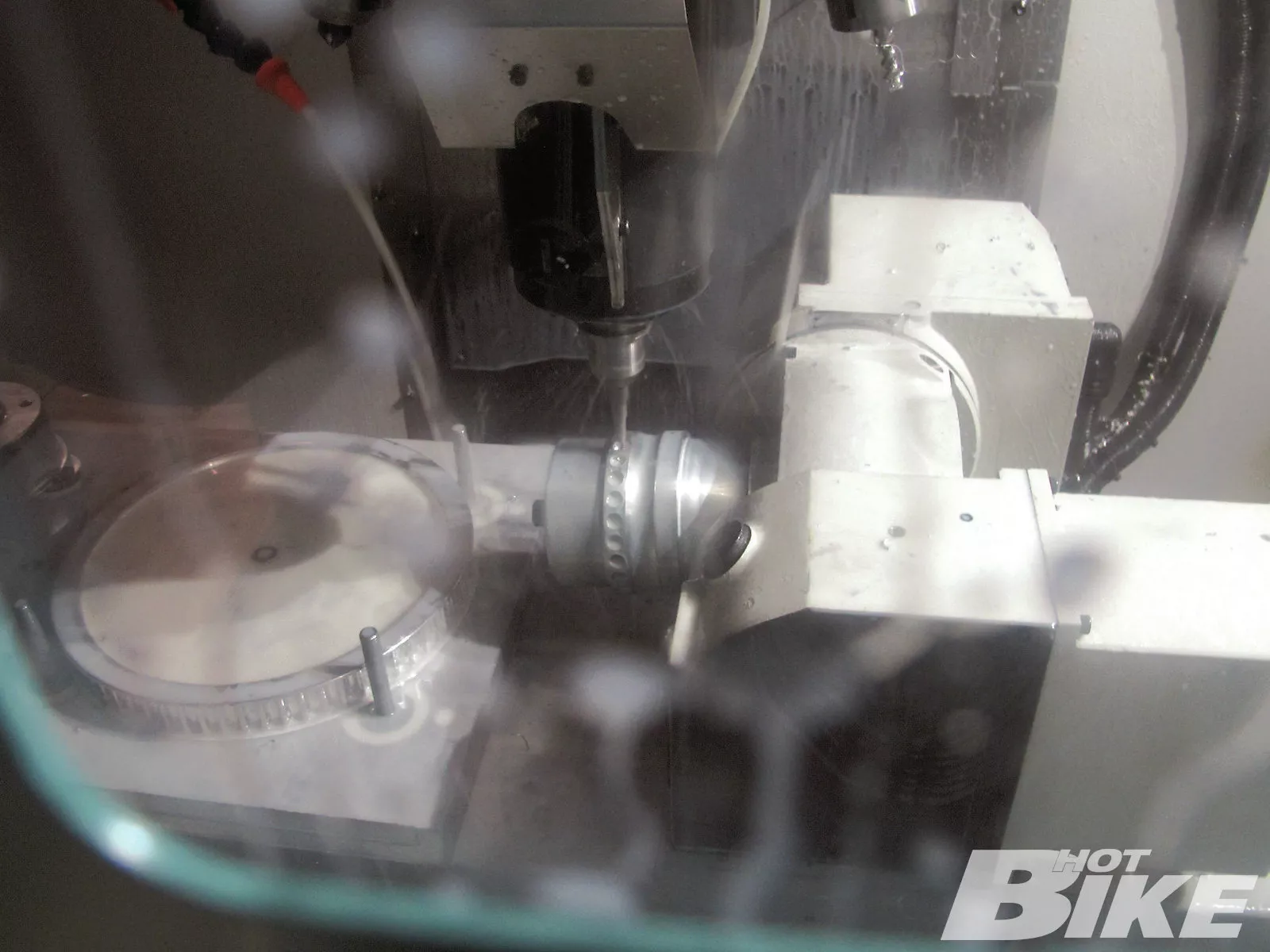

04. Here we see some raw hub material on the left and a hub that has been partially machined. The hubs are cut from T6-6061 round billet.

05. Once the shape of the hub is created, it is put into a Brother TC-S2D/-O CNC Tapping Center. This machine will drill and tap the hubs for the spokes to thread into. If you look closely to the left of the hub you can see a there is a pulley secured in the machine as well. This machine is also used to drill the pulley mounting holes.

06. Here is a comparison of a hub before and after the spoke holes have been drilled and tapped.

07. Moving over to the assembly side of the building, we see an assortment of hubs and various hub ends ready to be put into use. The hub centers are all a universal fitment for all wheels based on size (16, 18, 21, etc). RWW has designed the three-piece hub system so that the rim center and hub center are the same and whatever offset is needed for the various applications is in the hub ends.

08. Here we see a rim and hub center that has been laced and trued with Fat Daddy Smoothie spokes.

09. Before the hub ends are installed, wheel bearings get pressed into the outside of each hub end.

11. Here’s the hub end getting tapped into place over the pins and flush against the center hub.

12. The wheel is then flipped over and the crush tube is slipped in place.

13. Additional pins (arrows) are used on the other side of the hub center to locate the opposite hub end.

14. With the other hub end in position, bolts are then threaded into the assembly to secure it all together, and the wheel is complete.

15. Another one of RWW’s new products is an aluminum rim with a smooth surface. These rims are made from extruded aluminum that is reverse rolled and then the ends are welded together.

16. This smooth aluminum rim (front) offers a much cleaner look than the stepped lip surface on the steel rims RWW offers (back). Another benefit of the aluminum rims is that they are much lighter than their steel counterparts. We weighed a steel 21×3.5-inch rim and it weighed 10.5 pounds, whereas the same size aluminum rim weighed 8 pounds.

17. When it comes to billet wheels, RWW starts with aluminum blanks like this.

18. The blank is then secured in a CNC machine where it takes about 45 minutes to cut out the design.

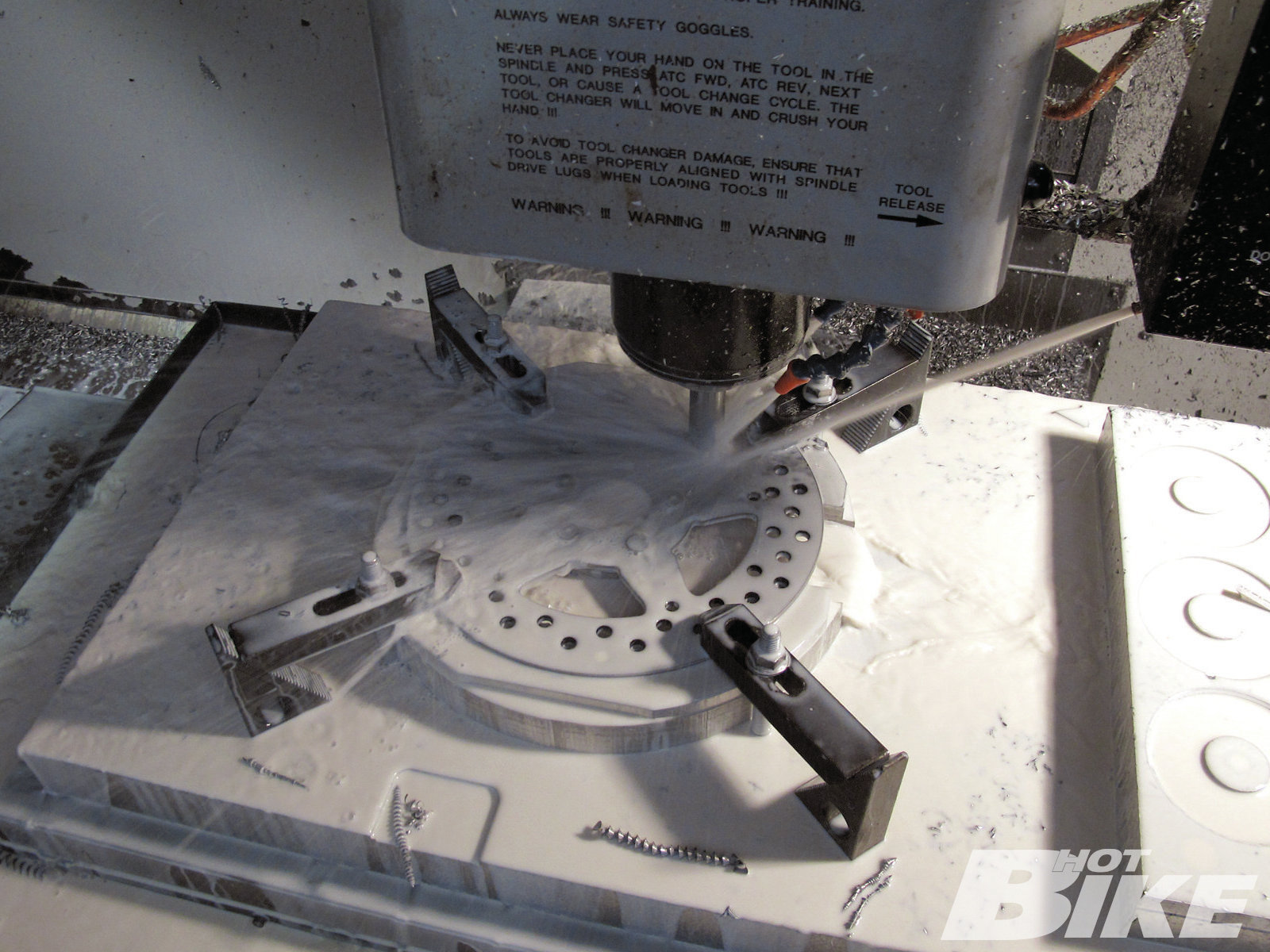

19. The rotors start out as blanks as well and then the windows or spokes (depending on the design) are cut and then the mounting holes are counter sunk. The blanks come pre-drilled with the venting holes.

20. This is one of RWW’s new Fat Daddy Soft Lip rims. Once again this rim features a smooth rim surface that allows RWW to customize the wheel even further by engraving the rim surface. As you can tell, this wheel has the popular black powdercoat and machined look that’s all the rage.

21. Same as previous, however this wheel features a machined accent running around the outer lip of the rim and also has Ride Wright Wheels cut into the lip as well. Like RWW’s wide array of spoke, hub, and rim powdercoating color options, the Soft Lip rim offers another level of nearly endless customization.

22. This is a wheel outfitted with Blade spokes. The Blade spokes features 3D CNC-milled grooves that run from one end of the spoke to the other. The grooves are about 1/8 inch deep at the hub end and then slightly taper as they run out towards the rim. Before being milled, the Blade spokes can be powdercoated for a two-tone effect between the chosen color and raw stainless steel.

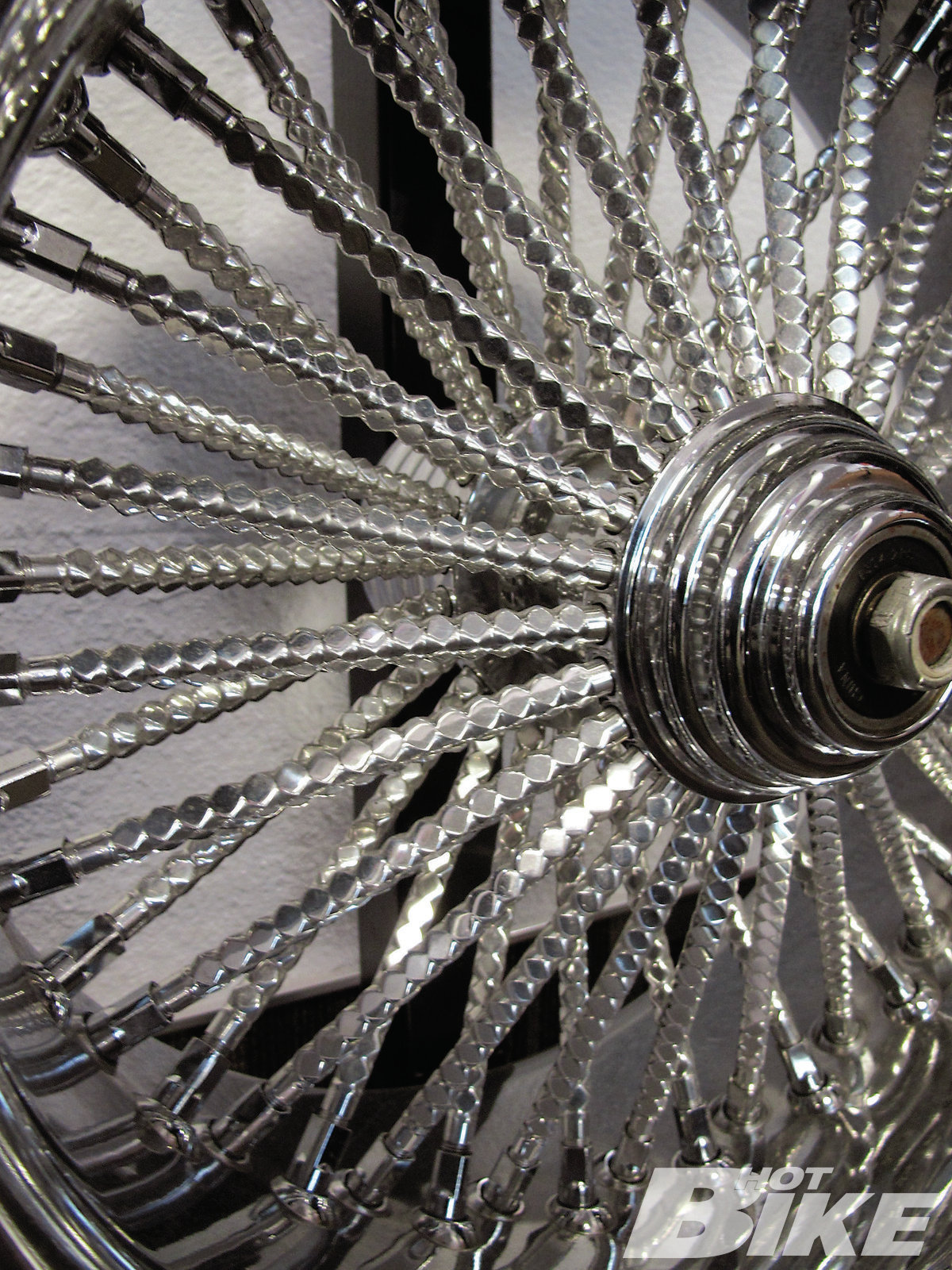

23. Here is a wheel laced with the Twista spokes.

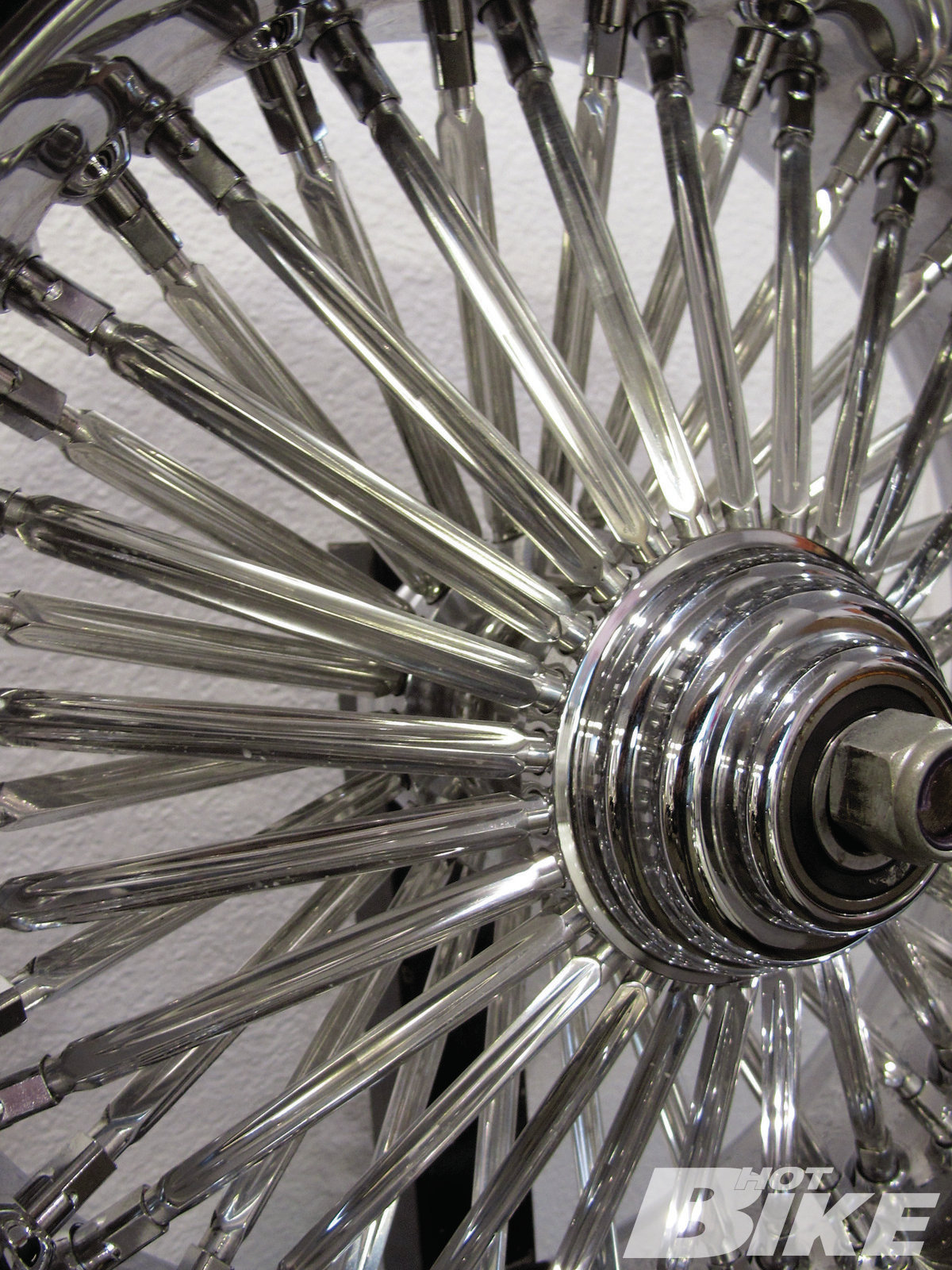

24. And for something totally different, RWW offers the Jewel spoke. The spokes are intricately machined and polished so that they glimmer in the sun like diamonds.

25. Lastly, if spokes aren’t your thing, maybe one of RWW’s new billet wheels will tickle your fancy. This Empire wheel features a riveted outer band with a mix between machined and solid 3D blades. Basically, no matter if it’s billet or spokes, chrome, polished stainless steel, multicolored powdercoat, or a combination of styles and colors, RWW can get you rolling and noticed.

So far with our Made in America series we’ve spent some time in the Midwest with National Cycle and Revolution Performance, now we’re back in the West Coast where we stopped in to visit with one of our neighborhood manufacturers, Sam Wakim, of Ride Wright Wheels (RWW). If you’re a long time reader, you may remember back in the November 2006 issue in which we visited Sam’s shop. In that article we showed how one of Sam’s most popular wheels, the Fat Daddy 50 Spoke, went from a rim band, hub, and a collection of spokes to complete wheel ready to roll down Main Street.

While Sam hasn’t reinvented the wheel, since that article back in 2006 he has definitely improved upon not only his patented Fat Daddy design but also his hub design, as well as expanded into creating a line of billet wheels for those who might want something a little more flashy than a spoked wheel, which is actually hard to do since Sam offers his spoked wheels in just about any hub, rim, and spoke color combination you could think of. Basically, if you wanted a set of wheels to commemorate that acid trip you had back in high school, RWW would be happy to oblige.

While RWW still offers its 40, 60, 80, and 120 cross-laced spoke wheels with the more traditional, skinny 3/16-inch spokes in round, twisted, or diamond-cut, some of Sam’s latest contributions to the world of wheels include Soft Lip rims featuring machine accents, Jewel, Twista, and Blade Fat Daddy spokes, and most importantly, a modular three-piece hub. Sam has received a patent on his three-piece hub design (for wire wheel applications), which utilizes a universal center hub and variety of hub ends that allow his company to quickly and easily set up any H-D or import bike with wheels. So what does this mean for you, the end user? Essentially it’s a one-hub-fits-all application, so if you purchase a set of RWW spoked wheels for a specific bike, and then you sell that bike and get a new one, you can keep your wheels and get new hub ends fitted to the wheels for your new ride—saving you the expense of buying a new set of wheels. Or, say you were running a single disc up front and wanted to go to a dual disc (or vise versa), you could just swap out the hub ends for either application. There’s a variety of options/applications the universal hub can be used for.

Now, about that billet stuff. Several years back Sam invested in more machinery, which allowed him to expand his line of products to include billet wheel designs. The addition of more CNC machines and mills also allowed Sam to take on manufacturing products for other companies, one of which was Rampage Wheels. And with the recent passing of Rampage’s founder, Wendell Smith, Sam has taken on full responsibility of the wheel line to ensure that Wendell’s passion for creating clean and elegantly designed wheels lives on.

Follow along as we tour through the RWW facility. HB

Source:

Ride Wright Wheels

(714) 632-8297 | ridewrightwheels.com