Twin Cam Engine Build Part 2

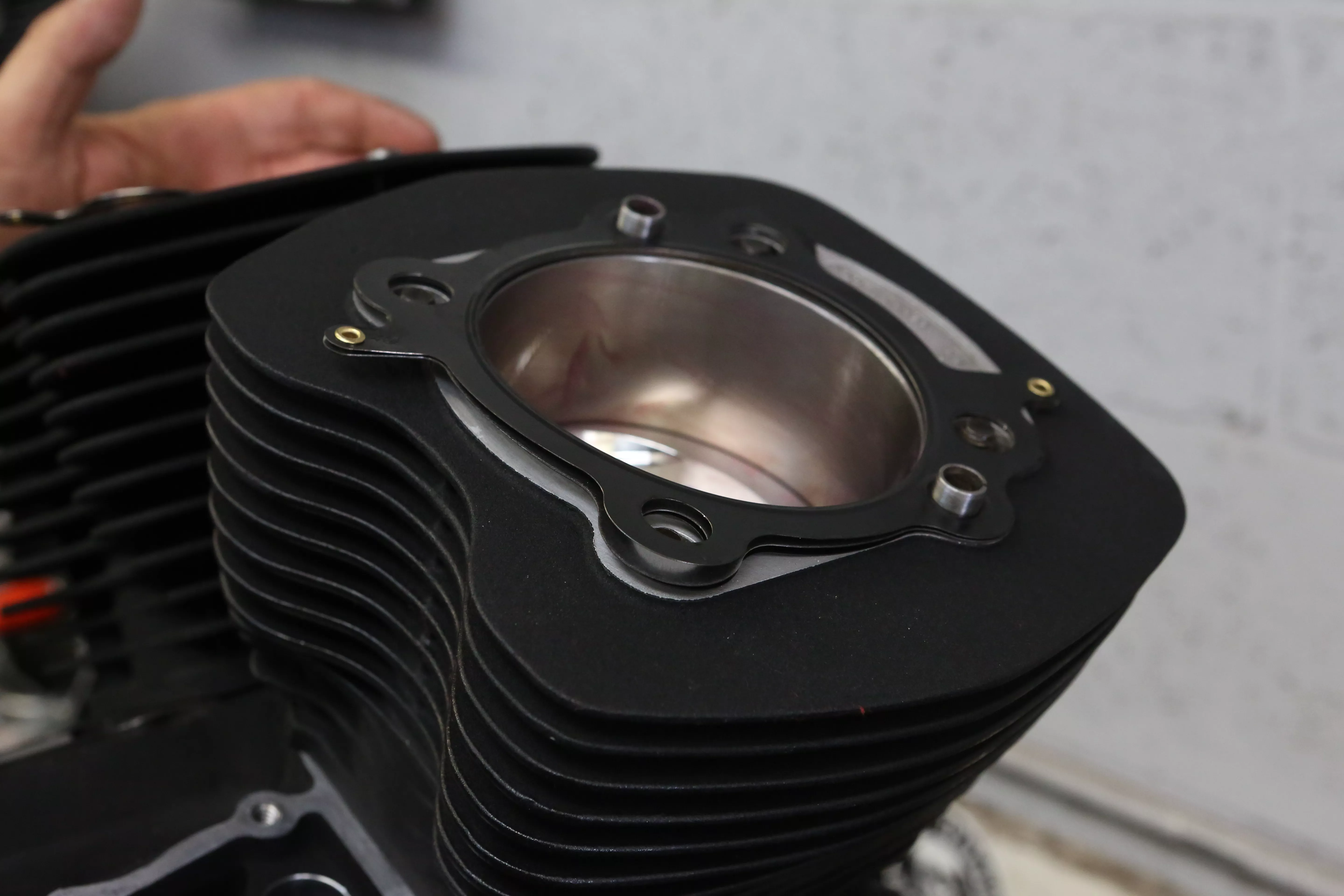

Install your head gasket. We are using a Cometic 0.030 MLS head gasket. Head gaskets vary in thickness, so be sure to use the recommended thickness head gasket for your specific setup.

Photo: Hot Bike Staff

As you may recall from Part 1 of this tech how-to, we pulled the Twin Cam “A” motor from its 1999 FXDX home after it hit 100,000 miles. We broke it down, inspected the parts, and then sent the lower end to Darkhorse Crankworks (DHC) so its squad of bottom-end experts could rework the tired components. Working with Dave Mackie Engineering (DME), we concocted a solid 107ci top end using bored H-D cylinders and some DME Mega-Sphere pistons, complemented by a DME cam. Both DME and DHC are known for their superior quality and attention to detail, so it was a pleasure to assemble this motor knowing the end result would be a powerful yet balanced blueprinted motor.

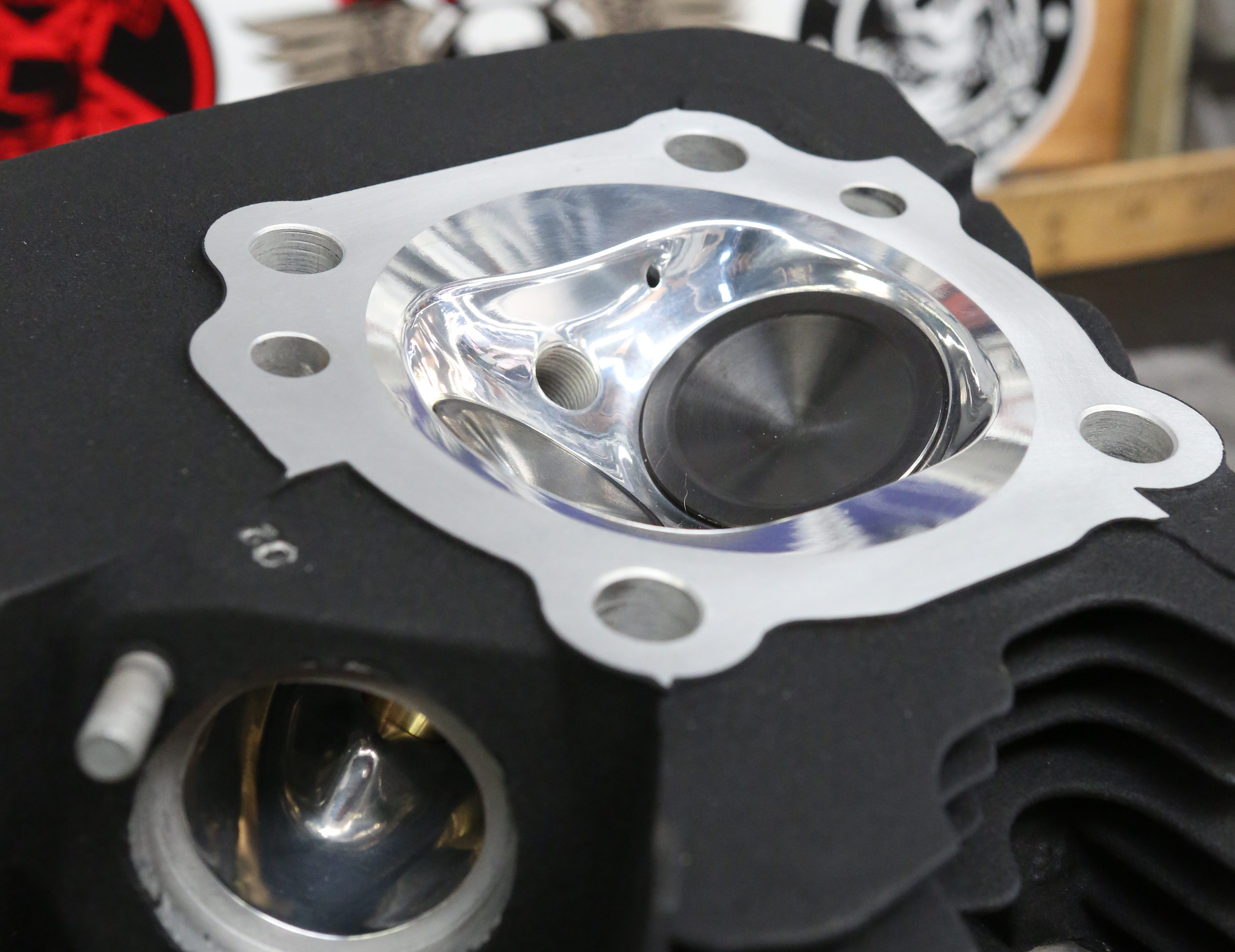

Next, we proceed to install the cylinder heads. We are using a pair of DME Mega-Sphere heads that have had their combustion chamber, exhaust, and intake cleaned up for optimum performance.

Photo: Hot Bike Staff

Place the cylinder head on top of the cylinder and head gasket. Install the four head bolts. There should be two long and two short ones.

Photo: Hot Bike Staff

When installing the cylinder heads, be sure to verify your pistons are installed in the correct direction and not coming in contact with the head surface.

Hot Bike Staff

After placing the cylinder heads onto the motor, follow the torque sequence directions that come with the head gaskets. Since there are a few kinds of head gaskets, you want to be certain to follow the manufacturer’s instructions for a proper gasket seal.

Hot Bike Staff

Next, we prepare to install the rocker arms and supports. After measuring the rocker bushings and shafts, we apply an ample amount of assembly lube to be certain the valve train can move freely upon start-up.

Photo: Hot Bike Staff

Tighten the rocker support plate and install the rocker arms as described in the service manual.

Photo: Hot Bike Staff

Place you rocker box gasket on the lower rocker box, and place the top cover on to the motor.

Photo: Hot Bike Staff

Tighten the rocker box bolts as per the service manual to a torque of 90 to 120 inch-pounds.

Photo: Hot Bike Staff

For this build we will be trying out the S&S reed breather for Twin Cam motors. To begin installation, simply remove the wave spring from the breather. Make sure to inspect the breather and clean any debris from the unit.

Photo: Hot Bike Staff

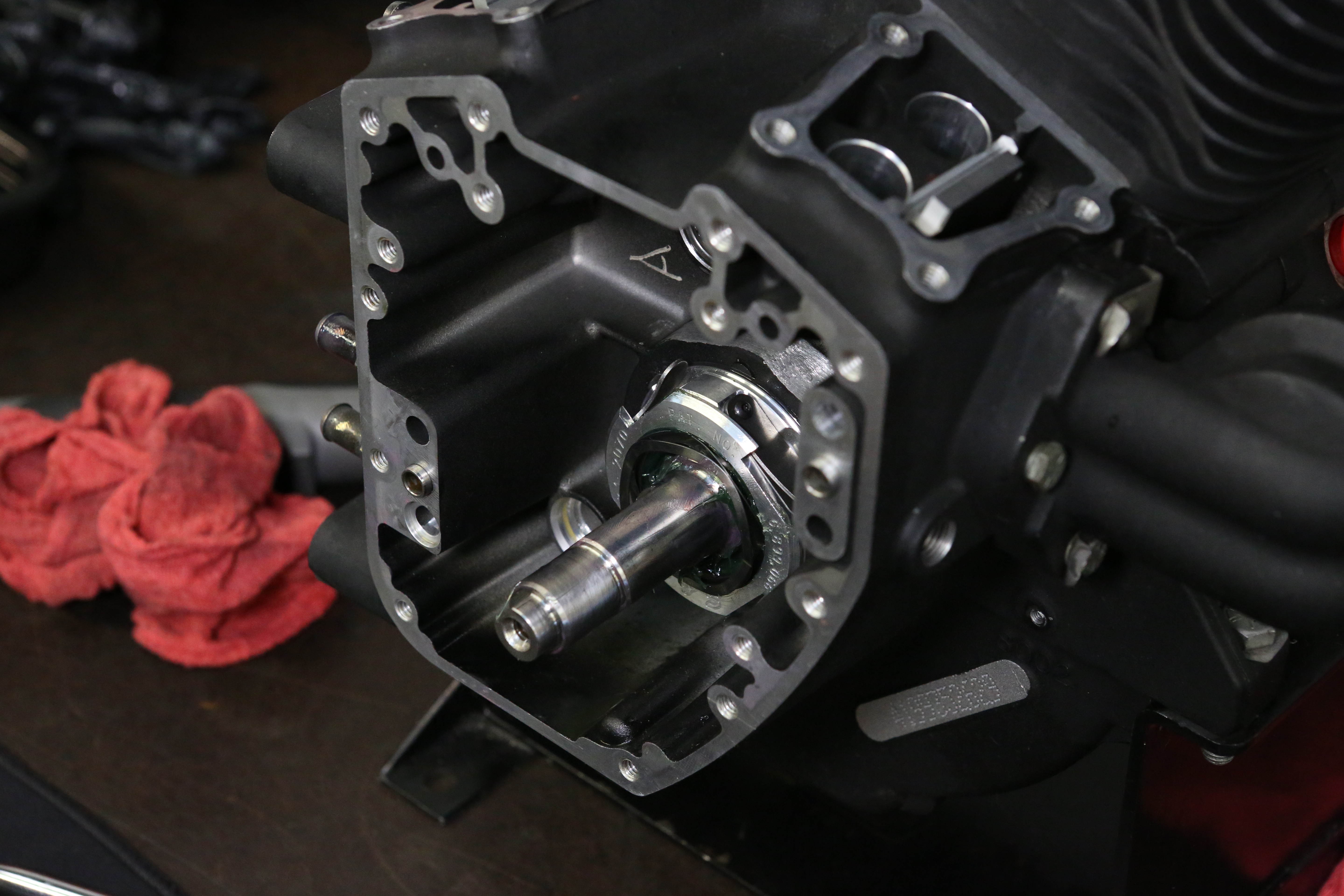

Press the S&S reed breather into the case bore. Place some grease in the outer bore of the breather, and place the wave spring into the center. Then we installed the oil pump and camplate.

Photo: Hot Bike Staff

Sources