Twin Cam Engine Build Part 4 of 5

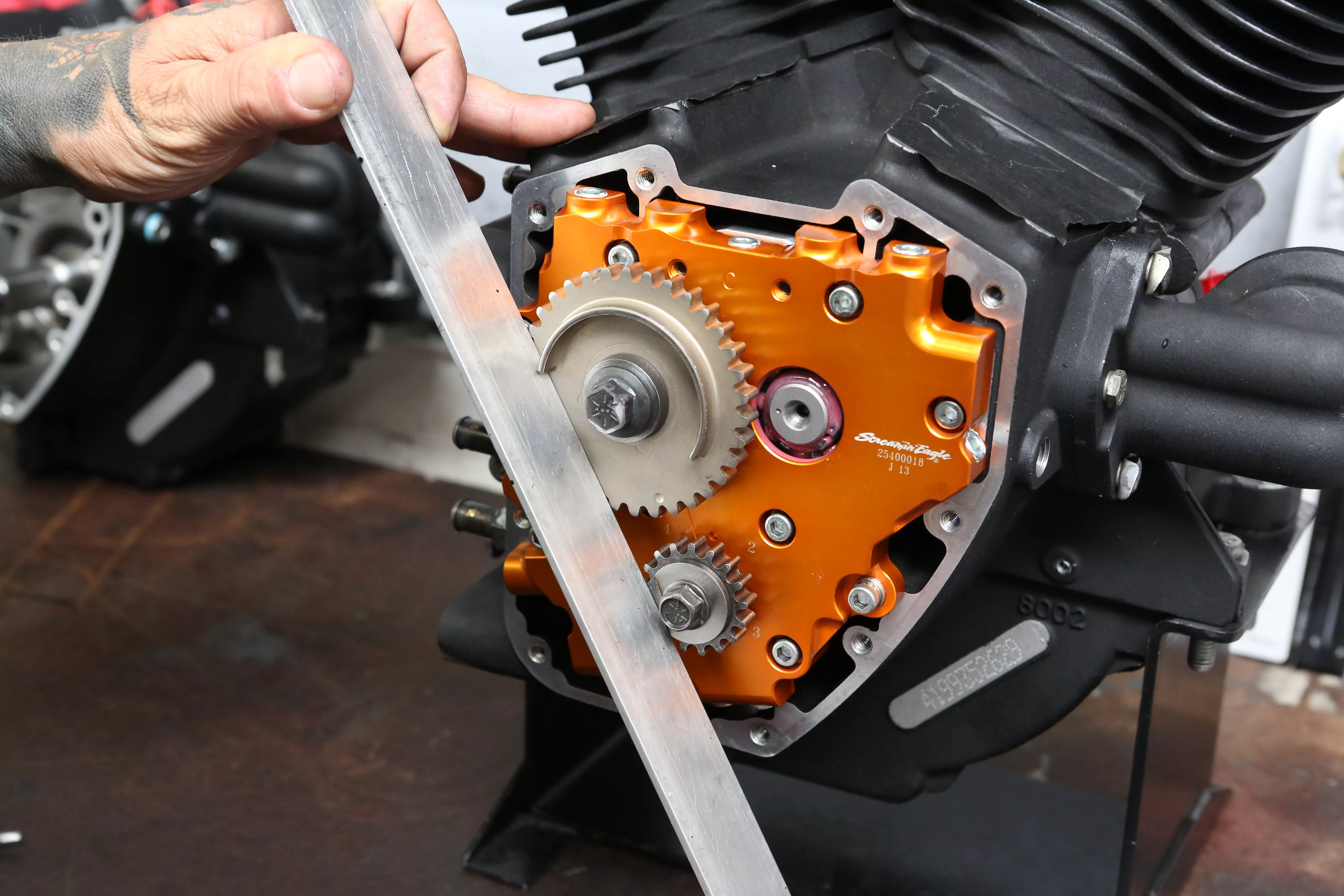

After tightening the two sprockets retaining bolts, place a straight edge over both sprockets to measure if your spacers are in alignment.

Photo: Hot Bike Staff

Let’s finish the cam installation and move on to the lifters. If you’re just now joining us, we’re rebuilding the Twin Cam A from a `99 Harley FXDX. After a 100,000 miles of loyal service, the motor had earned a spa day.

After we broke it down, we inspected it, and then sent the lower end to Darkhorse Crankworks (DHC) so its squad of bottom-end experts could rework the tired components. Working with Dave Mackie Engineering (DME), we concocted a solid 107ci top end using bored H-D cylinders and some DME Mega-Sphere pistons, complemented by a DME cam. Both DME and DHC are known for their superior quality and attention to detail, so it was a pleasure to assemble this motor knowing the end result would be a powerful yet balanced blueprinted motor.

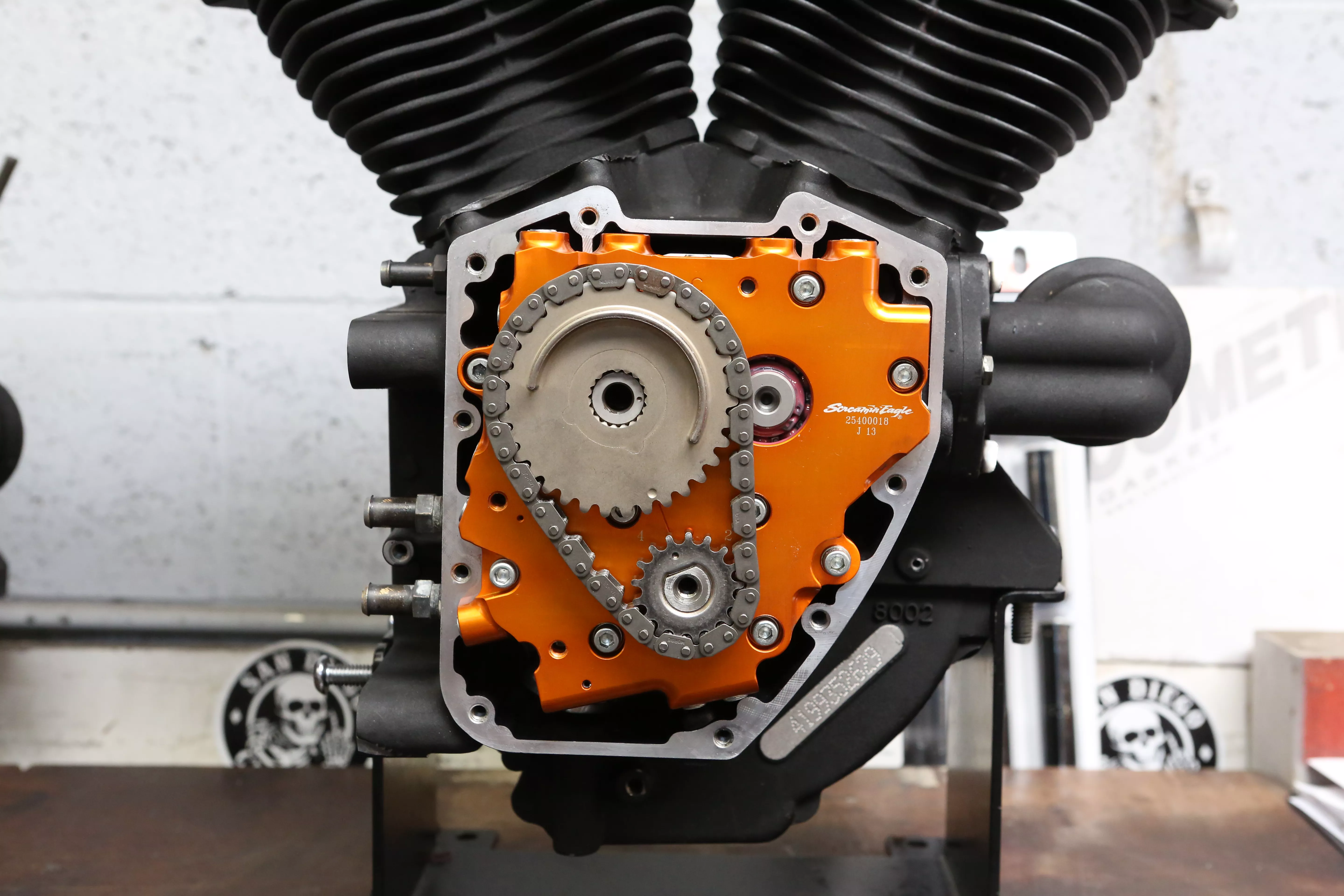

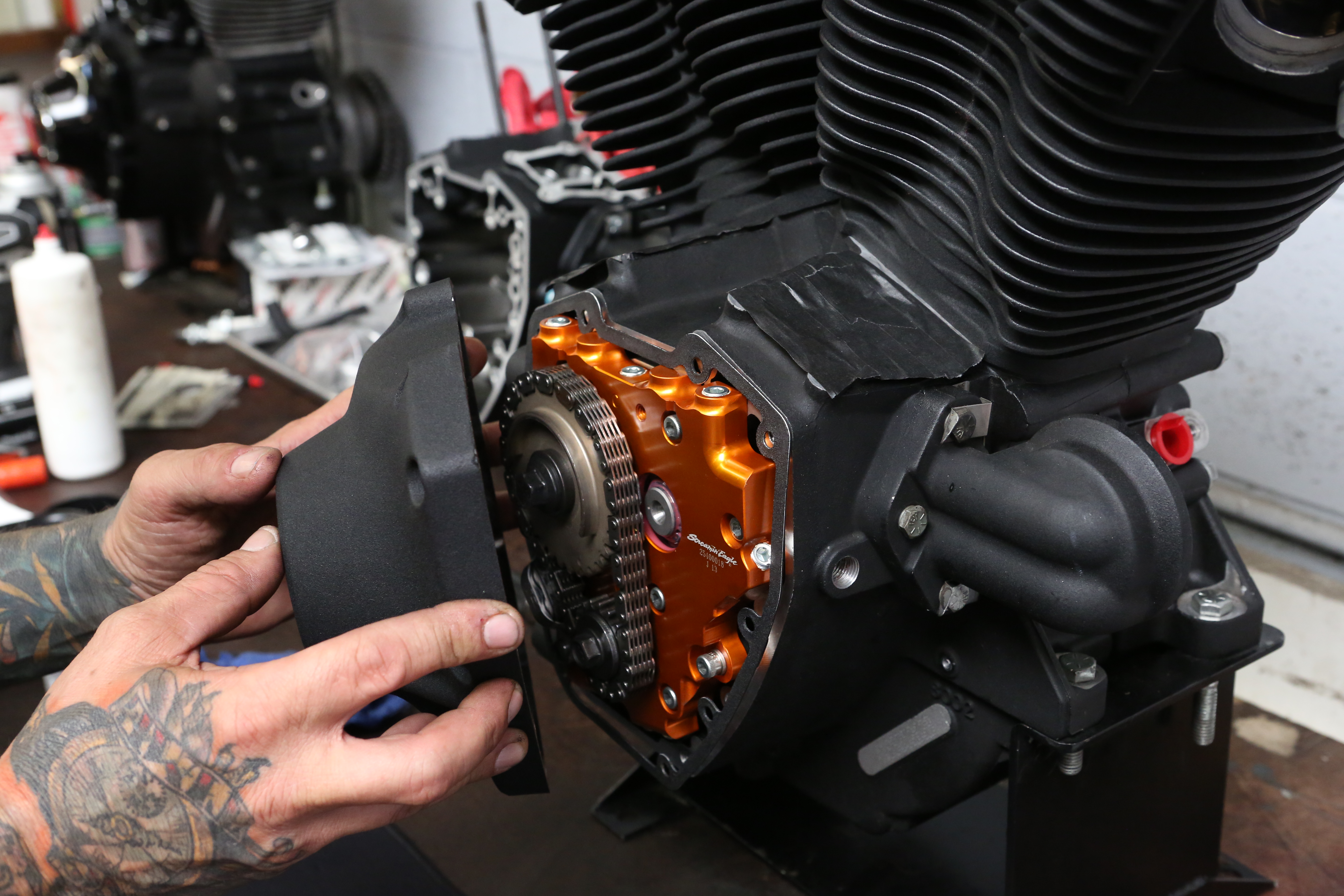

Pictured here is the correct sprocket spacing with the retaining hardware removed.

Photo: Hot Bike Staff

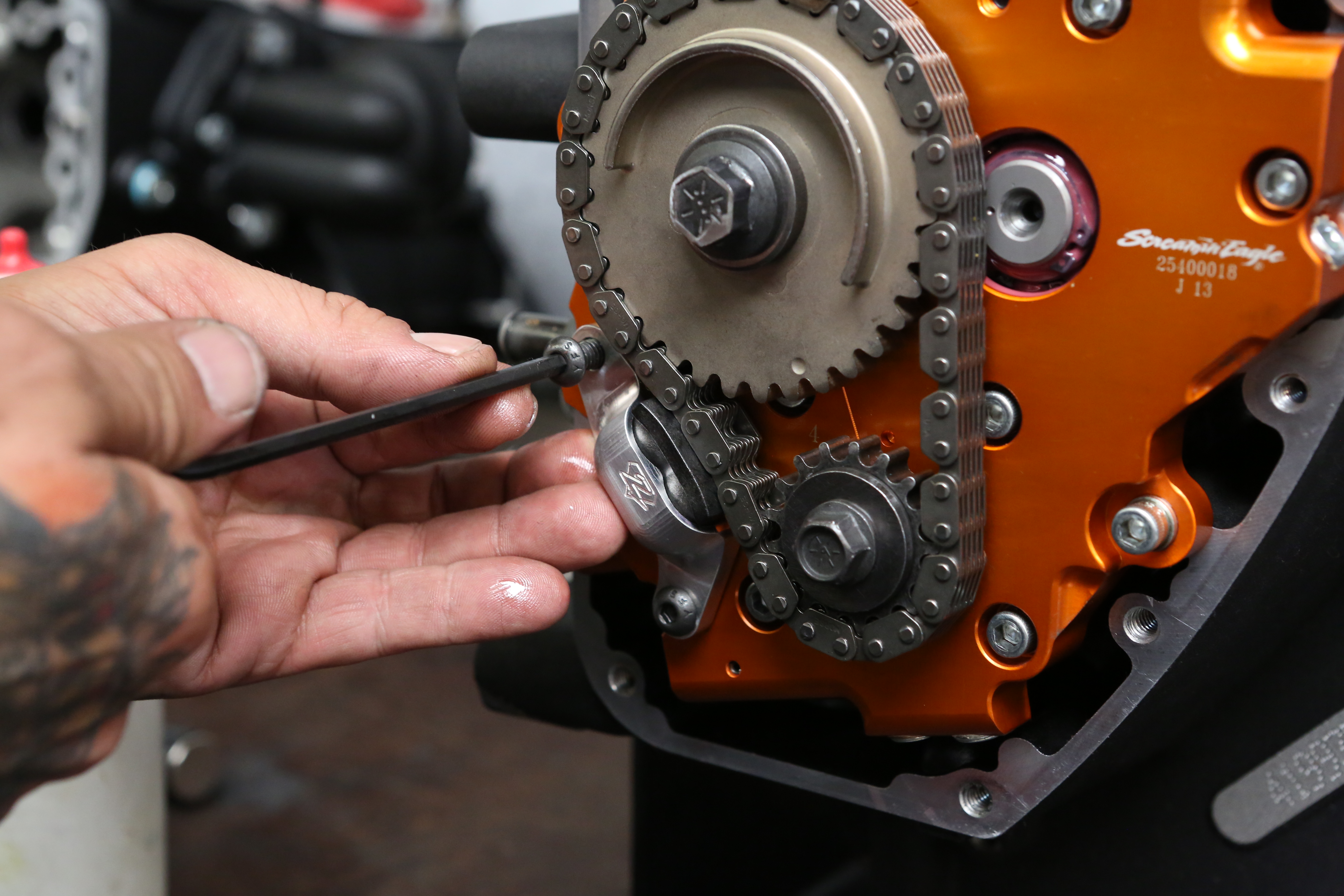

Using a JIMS sprocket-locking tool, lock your cam sprockets and torque the cam sprocket bolts.

Photo: Hot Bike Staff

Next we take a look into the Zipper’s Performance hydraulic cam chain tensioners. We are looking inside to make sure the bore is clean and has no foreign material from production caught inside.

Photo: Hot Bike Staff

RELATED | MORE TECH

Using a small amount of H-D 20/50 motor oil, we filled up the tensioner pistons.

Photo: Hot Bike Staff

Install the cam chain tensioner and torque to factory specs.

Photo: Hot Bike Staff

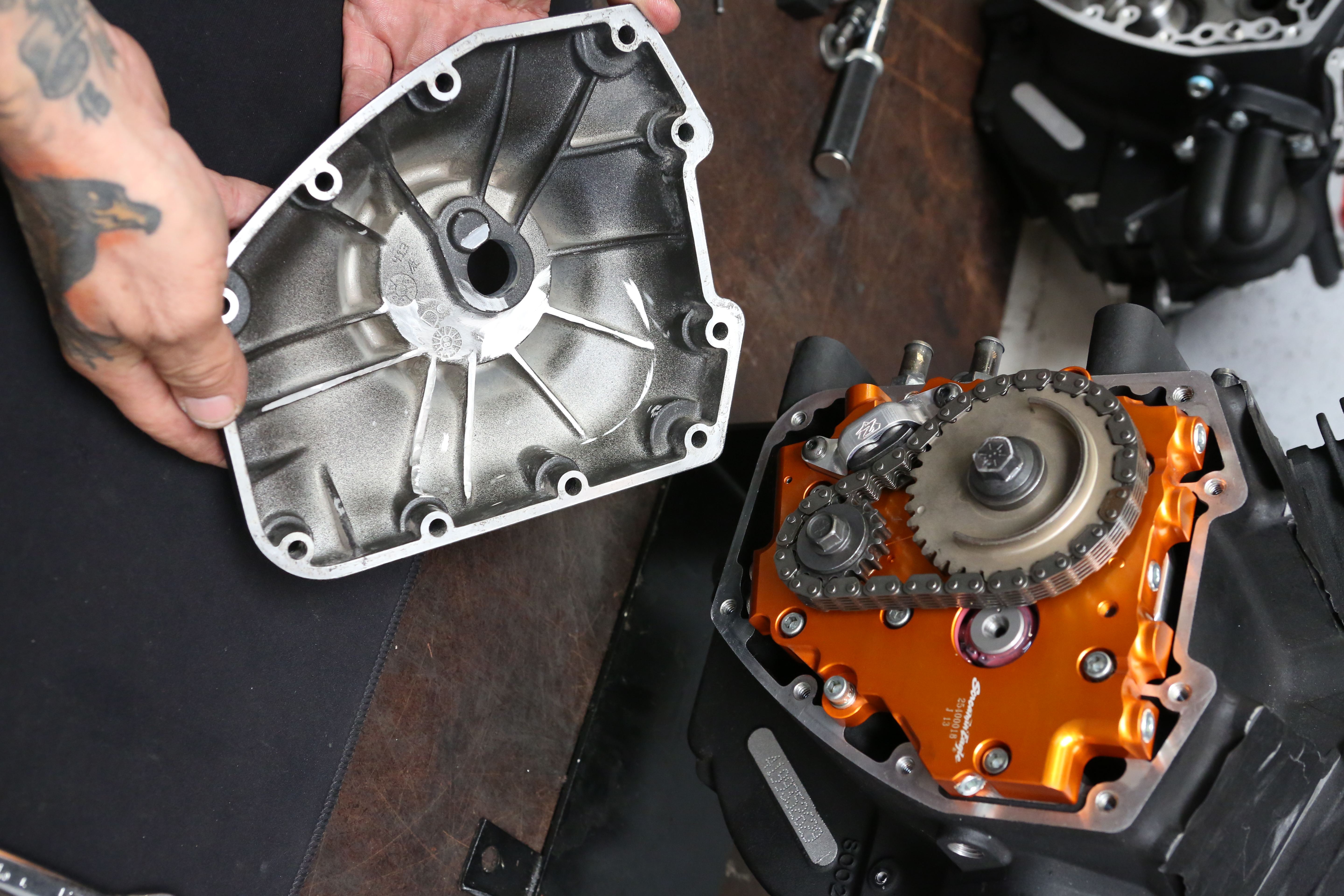

Since we are using Zipper’s cam chain tensioners, it is recommended that some of the webbing inside the cam cover be removed so the tensioner does not hit the inside of the cover.

Photo: Hot Bike Staff

You might have to place the cover on and off a few times to make sure you have removed all the material away from the tensioner housing.

Photo: Hot Bike Staff

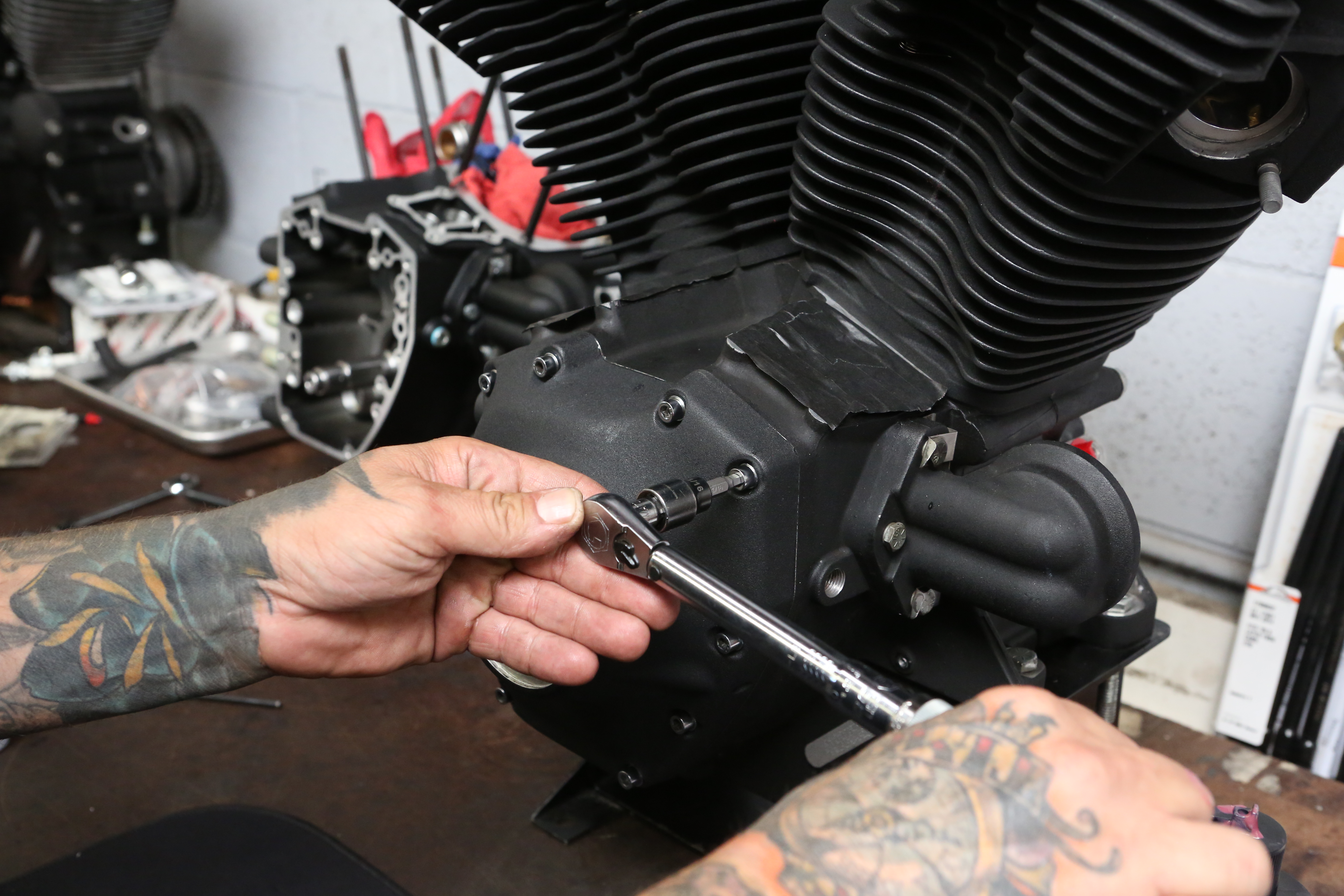

Once the cam cover sits flush, install the cam cover bolts and torque to 90 to 120 inch-pounds.

Photo: Hot Bike Staff

Pre-soaking lifters is always a great idea to bleed all the air out of the tappet body so when starting the motor the lifters will be somewhat oil filled and therefore have less to do when the motor is first fired.

Photo: Hot Bike Staff

Sources