Works Even When It’s Idle

An Evo Nightrain was our lab rat. Both the stock and T.P. oil pumps were tested under the same conditions: at idle with the engine cold, at idle with the engine hot, and at 2,500 rpm with the engine hot.

Eric Bennett removes the nosecone. Harley uses rivets instead of screws on the timing cover, so we had to drill them out. Then, he used a Trock puller to slide the nosecone off. You’ll have to remove the exhaust if it interferes, but we were lucky.

T.P. provided us with a special testing nosecone with an outlet hose for the flow test. Once it was on the bike, we were ready to test the stock pump.

We used a graduated cylinder and a watch to see how much oil flowed through the stock pump in 60 seconds. At cold idle (850 rpm), the pump circulated 8 ounces of oil; when hot, it pumped zero ounces at idle. Once the motor was warm, we saw a 18.5-oz flow at 2,500 rpm.

Off comes the stock pump. We disconnected: the oil tank vent-line at the pump; the main oil-feed hose at the pump; then the oil filter-to-oil pump cover manifold oil hose. Removing the pump is a multi-step process, involving many small parts that is made easiest by consulting your service manual. The most important caution is to make sure the drive gear shaft isn’t pushed into the gearcase.

We also used this as an opportunity to change the oil and filter before going on to the new pump. Taking the oil out, along with blowing a fan on the motor, cooled the engine much faster than waiting for it to cool off on its own.

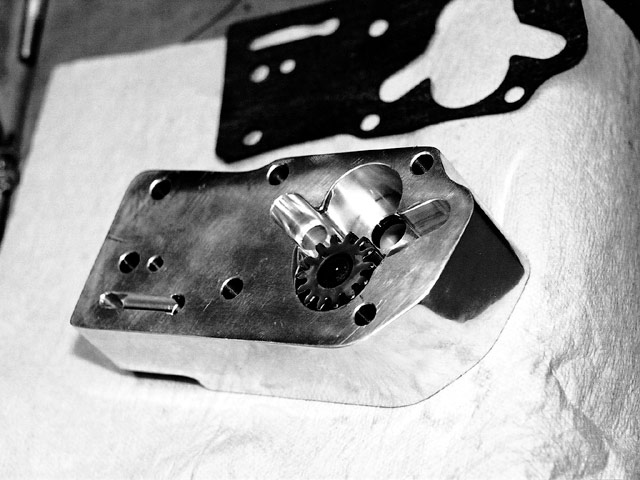

Stock (left) versus T.P. (right). When Harley began to use hydraulic tappets, they realized there wasn’t enough flow to keep them lubricated. They addressed this problem by using an oil pump with two valves on the pressure side. These flow oil to the tappets instead of the crank area when the bike is started and running at idle. The crank area receives whatever oil manages to splash into it from the top end. Once the engine was running over 2,000 rpm, the pump stopped sending oil to the tappets and began sending it to the crank area. Both tappets and crank would receive lubrication while riding. T.P. Engineering’s pump…

…flows oil to the tappets and crank area simultaneously — even at idle. Their oil pump has three valves to Harley’s two. All three have different cracking pressure (the oil pressure required to open the valves) that regulate the opening and closing of the valves. Once the engine is started, oil goes through the first valve and flows to the tappets. As oil flows and pressure builds, the second valve opens up, allowing precise flow to the crank area. As the pressure keeps building, the third valve regulates oil flow to the crank by either passing relief oil back to the feed side of the pump, or allowing the flow to continue to the crank. A set of high-precision check valve springs controls opening pressures to ensure adequate lubrication through the range of engine operation from idle to full throttle. This produces low-friction operation, successful scavenging of lubricated surfaces, and satisfactory cooling.

Before installing the new pump, we applied engine assembly lube to the idler gear on the scavenger side, so it spins freely until oil begins to circulate through the pump.

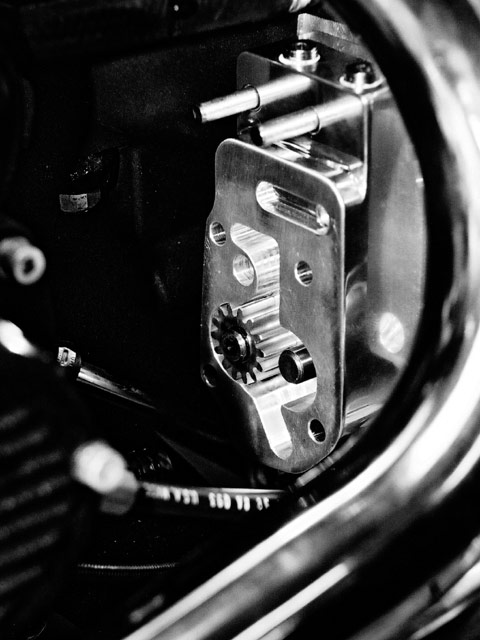

The installation steps are the reverse of the removal process, but Eric had a tip for us. He uses a set of bolts, that he cut the heads from, as a guide for mounting the pump properly. He exchanges the stand-offs for the pump cover bolts once the body is in place. The complete pump…

…looks like this. After we connected the oil hoses, it was testing time.

The tests were repeated under the same conditions as before. While cold, the T.P. pumped 8.5 ounces of oil. We rode it over the same course to warm it up, and it produced 0.5 ounces at idle (still set at 850 rpm — T.P. told us afterward that at 1,050 rpm, our results would’ve been as significant as the next part of the test), and 25 ounces at 2,500 rpm — about 30-percent more than it did cold.

The new high-flow oil pump is not only great for the bike, it also allows the motor to take full advantage of some new lifters. So, while we were making changes, we treated the engine to JIMS lifters.

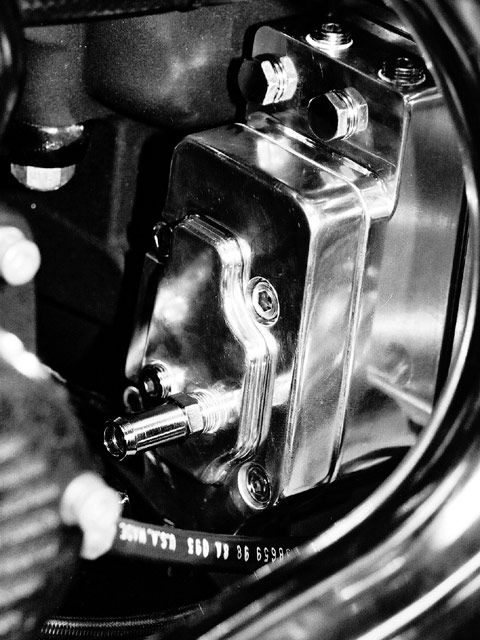

After testing, we replaced the nosecone with this beautiful billet one that T.P. sent us, along with the pump.

Summer weather brings great riding opportunities, but it also brings higher temperatures. And, if you ride to work in heavy traffic like we do, that can mean a lot of time spent at idle — and a lot of heat for your V-Twin engine. A situation that is not good for longevity — especially if the motor is hopped-up.

Compounding the problem further, Harley’s stock oil pump can’t circulate as much oil to the crank area at idle as it does when the motor is running at speed. T.P. Engineering offers a smart solution to this dilemma. They’ve created a three-valve, high-flow pump that increases flow levels, even at idle.

Given the high temperatures we’ve been getting in Southern California, we were eager to test T.P.’s pump on one of our bikes. They assured us that as long as we had our engine-idle set at 1,050 rpm (as the factory calls for), we would see significant flow-level improvements at that speed. They also caution against the trend today of setting your idle speed around 850-to-900 rpm — because it sounds good — since that speed flows no oil with any pump.

We took a T.P. pump and an 80ci Evo with a hot state of tune to Bennett’s Performance in Signal Hill, California, to see how well the pump flowed oil — both with a cold engine and a hot one.