Big-Bang Theory Meets A Harley-Davidson Counterbalanced Softail

In this Big Twin hop up we wanted to give a counterbalanced Softail engine some more oopmh, one that provided buckets of power on tap at any and all rpm.

Tim Barker

This article was originally published in the April-May 2000 issue of Cycle World’s Big Twin magazine.

It’s usually the second question that people ask about the new Twin Cam Beta Softails. The first question—submitted, obviously, by people who have never ridden one—is, just how smooth are those counterbalanced engines? The second—ordinarily asked by someone who either plans to own a Beta or already does—is, how smooth are they after they’ve been hopped up?

Answering the first question is a no-brainer: The Beta engines are so smooth that you may have a hard time believing they aren’t rubber-isolated in some way. The answer to the second one isn’t so easy.

Harley-Davidson’s engineers claim they designed the counterbalance system to retain virtually all of its vibration-killing effectiveness if the motor is modified with certain pieces of Screamin’ Eagle performance equipment. Okay, but what happens when you really start to lean on a Beta motor even harder? How smooth will it remain after being further energized with even greater displacement, reworked heads, more-radical cams, additional compression and such?

You won’t get much of an answer to that one from Motor Company officials; they’re loathe to even discuss the notion of modifying a Beta—or any Harley—with non-H-D equipment. All they’ll say is that they strongly recommend against it, and that if you deign to commit such a heinous act, kiss your new-bike warranty good-bye.

We know of quite a few people who have modified Twin Cammers along these lines, but none had done so on a counterbalanced Beta. So, when Bob Kimball expressed a desire to have his 2000 Fat Boy imbued with some serious horsepressure, we seized the opportunity faster than Ted Kennedy could accept a free cocktail. Kimball is a regular customer of Accu-True, the Costa Mesa, California, H-D repair and hop-up shop owned by Bruce Fischer, Big Twin’s Technical Consultant. Among Kimball’s stable of more than a dozen-and-a-half bikes are several modified Harleys—including a 104-cubic-inch nitrous FXR—so he knew precisely what he wanted. “Make it fast,” was his only mandate.

There are, of course, more possible ways to hop-up a Harley-Davidson than there are, well, Harley-Davidsons. So, working with Fischer and Kimball, our first order of business was to determine exactly what kind of “fast” we wanted. We ultimately decided to build a motor that would make at least 100 horsepower, but do it with a wide, flat torque curve that would top out at no less than 100 foot-pounds.

Big-bore cylinder swallows the stock piston with room—a quarter of an inch, actually— to spare.

Tim Barker

What we didn’t want to end up with was 100 peaky, high-rpm horsepower that would render the bike joyless to ride anywhere but on a dragstrip. To the contrary, we wanted an engine with buckets of power on tap at any and all rpm, one that would threaten to pop Kimball’s arms out of their sockets any time he dialed the throttle wide-open, whether at a walking pace in first gear or cruising speeds in high gear. Such an engine would also allow us to answer Question Number 2 and determine the effect of triple-digit horsepower on the smooth running of a counterbalanced Twin Cammer.

We felt that the most realistic way to achieve that magical 100/100 goal would be with yet another “100”—as in cubic inches. We called it the 1003 formula: 100 cubic inches, 100 horsepower, 100 foot-pounds of torque. Nice, round numbers. Easy to remember. Especially when the bike producing them launches you away from a stoplight like it was hit from behind by a speeding UPS truck.

To achieve that cubic increase, we used a Sputhe cylinder kit ($729, plus your stock cylinders in exchange) that adds 1/4-inch to the stock motor’s 33/4-inch bore. With it, the engine has a perfectly square, 4-inch-by-4-inch bore and stroke, for 100.5 cubic inches of displacement. Alan Sputhe produces the cylinders by boring out stock barrels and re-sleeving them to accept the kit pistons, which are JE flat-top models that retain the stock, 9.1:1 compression ratio.

To meet our target power levels, however, we felt that compression somewhere in the 10.5:1 neighborhood would be required. We could have simply swapped the 9.1 pistons for their higher-compression counterparts, but we decided against doing so—for good reason: The weight of the 4-inch, flat-top, forged-aluminum pistons in the Sputhe kit is virtually identical to that of the 33/4-inch, cast-aluminum stockers, whereas the domes on high-compression pistons make them heavier. Adding piston weight would alter the equality of forces between the rotating/reciprocating masses of the engine and the counter-rotating mass of the balancers. More simply put, the engine would have more vibration. So we decided to keep the flat-top pistons and raise compression by reducing the combustion-chamber volume of the heads.

For that task, we turned to Jerry Branch. A long-standing authority in the field of motorcycle cylinder-head design, Branch has helped Harley-Davidson develop quite a few heads for both production engines and factory racebikes. He currently offers ported and polished Twin Cam heads fitted with his own larger, 1.940-inch intake valves (original-equipment size is 1.875-inch) and stock-sized (1.610-inch) exhausts. For our application, we also had him mill .100-inch off the heads, which reduced the combustion-chamber volume from 85cc to 74cc, bumping the compression ratio up to 10.4:1.

We also did a little planning for the future. When preparing these heads, Branch normally sets up the clearance between the valve-spring retainers and the valve guides to permit as much as .600-inch of cam lift. But on our Fat Boy’s heads, he allowed for .630-inch of lift just in case Kimball decides to slip in a set of monster cams some time in the future. Normally, Branch gets $840 (plus your old heads in exchange) for his Twin Cam heads, but the extra work on our set tacked another $50 onto the cost.

For those very same reasons of planning ahead, we installed a set of Jims roller rockers ($415) in place of the stock rocker arms. The roller types are much easier on the valve stems when subjected to the greater loads imposed by high-lift cams.

Speaking of cams, we also went to Branch for those, choosing a set of that company’s T55 camshafts. Steve Brackett, who manages Branch Flowmetrics now that Jerry Branch is in semi-retirement, designed the T55s with moderate lift (.560-inch) and duration (255 degrees) to help generate strong low-end and midrange torque and allow the engine to be very ridable. But he also gave the cams quite a bit of overlap (47 degrees), which slightly compromises bottom-end grunt but helps the engine produce excellent top-end power without a bunch of lift. Branch gets $435 for the cam kit, which includes pushrods, gears and bearings.

To let our modified engine rev farther, we eighty-sixed the stock, 5600-rpm ignition module in favor of a Screamin’ Eagle 7000-rpm replacement ($199.95), which comes with a matching coil. And the stock, 40mm Keihin CV carburetor was swapped for a Mikuni HSR45, which is practically identical to the ubiquitous HSR42 carb except for its 3mm-larger venturi. The carb is packaged in a $595 kit that includes intake manifold, breather assembly, air cleaner and all necessary hardware for installation.

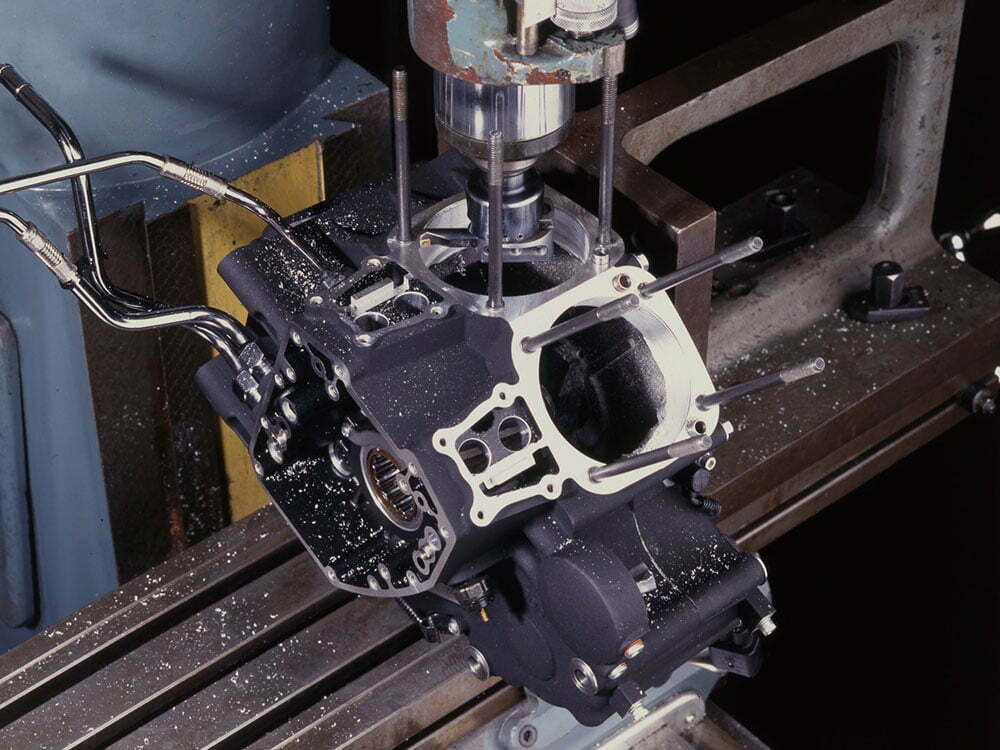

Boring the engine cases is only a one and a half hour job after they are removed from the chassis and stripped for machining.

Tim Barker

For exhaust, knowing that Harley-Davidson engines are so very pipe-sensitive, we decided to try several different systems. We did, of course, use the old reliable: a 2-into-1 Thunder Header ($459) that has produced excellent power throughout the entire rpm range on several of our hop-up projects.

We also tried two slightly different Hooker exhausts: a 2-into-1 system ($510), and a brand-new, 2-into-2 style ($575). Both use Hooker’s tuneable baffle system in which you can adjust the back-pressure to the “H” setting for the best horsepower, or to “T” for better torque. Both pipes also are built using Hooker’s Step-Header technology in which the first part of the header uses 15/8-inch-diameter tubing, with the last part opening up to 17/8 inches. Hooker says that this helps broaden the powerband by giving the system two different inherent tuning frequencies, one best-suited for lower rpm, the other for higher revs.

Last but certainly not least, we replaced the stock fuel petcock with a freer-flowing Pingel ($79.95)—an absolute must for just about any serious engine modification on a Harley-Davidson. We wanted to ensure that our big, thirsty Fat Boy would never starve for petrol at higher rpm.

To establish a performance baseline, we ran the stock Fat Boy on our Dynojet dyno before disassembling its engine. And we got a bit of a surprise. Before the run, we suspected that the added frictional losses of the dual counterbalance system (which involves a chain that passes over or around three sprockets while sliding along the surface of a long tensioner shoe, added to the friction of two balance weights spinning in their bearings) would kill a horsepower or two, but that didn’t seem to be the case; the stocker pumped out 64.4 horses at 5250 rpm and 72.5 ft.-lb. of torque at 3300. These are the best stock Twin Cam numbers we’ve seen so far, surpassing those produced by several non-counterbalanced TC 88s that Big Twin has tested on the same Dynojet.

After completing all the modifications and carefully breaking-in the new internals for several hundred miles, it was showtime. We lashed the Fat Boy onto the dyno once again and proceeded to make more than 70 separate runs, trying just about every reasonable combination of exhaust system and jet size. When the smoke finally cleared and the big-bore Beta was no longer rattling the rafters, we had achieved our sought-after numbers: 101 horsepower at 5700 rpm and 108 ft.-lb. of torque at 4300. Success!

Just as important as those peak figures, though, is the shape and width of the torque curve. The engine first reaches 90 ft.-lb. as early as 2200 rpm (remember, the stocker’s absolute peak was only 72.5 ft.-lb.), briefly dips down into the high eighties between 2500 and 3000 rpm, and then leaps back up above 90 and stays there until nearly 6000 rpm. And it remains above 100 ft.-lb. from 3600 rpm all the way to 5100.

In real-world terms, this means that when you whack open the throttle on this 100-inch Beta, especially above 3000 rpm, the bike accelerates right now—no hesitation, no waiting for the revs to build, no downshifting. And when you do it, you’d better have someplace to go, because you’re gonna be there in a heartbeat.

Those best power and torque figures were obtained with the 2-into-2 Hooker exhaust set on “H.” The 2-into-1 Hooker, also set on “H,” delivered 99 horsepower, just two shy of the best, but only made 105 ft.-lbs. of torque. The 2-into-1 Thunder Header produced 98 horsepower but managed 107 ft.-lbs.of torque, almost equalling the best run of the 2-into-2 Hooker.

Just for giggles, we tried both Hooker systems with their baffles set in the “T” torque position. In both instances, the dip in the powerband between 2500 and 3000 rpm was reduced by about half, even though the overall amount of torque all across the range was down by as much as 12 ft.-lbs., and peak horsepower was off by almost 10. The Hookers are much quieter at that setting, but that silence comes at the expense of considerable performance.

While we had the opportunity, we also experimented with a Screamin’ Eagle 44mm CV carburetor ($299.95, plus $69.95 for the required intake manifold), a Keihin unit that is very similar to the stock carb except for its 4mm-larger venturi. And frankly, it impressed us enormously. With that carb and the 2-into-2 Hooker installed (and set on “H”), the Fat Boy hammered out just under 100 horsepower (99.8) at 5750 rpm, and its torque peak was 105 ft. lb., just 3 points lower than with the 45 Mikuni. Most interesting, though, was that the Keihin took about 80 percent of the dip out of the torque curve between 2500 and 3000 rpm. The overall torque output in that rpm range was several foot-pounds lower than with the Mikuni, but the smoothness of the curve was impressive.

So much so that, when we returned the bike to Kimball, he rode it for a few days with the 45mm Mikuni in place and then asked Fischer to install the 44mm CV. After his very first ride with that carb, Kimball proclaimed, “I’m leaving this one on. I like it.”

It’s not hard to figure out why. The engine will accelerate more vigorously at lower rpm with the Mikuni if you gently roll the throttle wide-open rather than just snapping that huge venturi to WFO with a quick twist. But no matter how abruptly you open the throttle with the Keihin, the vacuum-operated slide only lifts as far and as fast as the engine can handle (which is the very principle behind CV, or “constant velocity,” carburetors). The bottom line is that you can accelerate slightly more quickly in that rpm range with the Mikuni if you’re very throttle-sensitive, but the Keihin CV performs almost as well no matter how carefully or carelessly you arrive at full throttle.

Okay, so Project 1003 transformed a 2000 Fat Boy Softail from a nice, plain-vanilla cruiser into a rompin’, stompin’ thunderbike; but at what cost?

Well, horsepower seldom comes cheaply, and this project was no exception. All the various bits of hardware added up to just over $3900, and then you have to figure in the labor charges. Installing the big-bore cylinders required removal and complete disassembly of the engine (about an 11-hour job) so that Fischer could bore out the cylinder-spigot holes in the crankcases (11/2 hours) to accept the fatter cylinder sleeves. And, because milling the cylinder heads effectively dropped the combustion chambers closer to the pistons, Fischer also had to machine bigger reliefs in the piston crowns (1 hour) to prevent the valves from hitting them.

So, based on an average of about $50 per hour (shop labor rates generally run between $45 and $55 an hour, so we’ll split the difference), figure about $550 for removal, disassembly, reassembly and reinstallation of the engine, plus about $125 for boring the cases and fly-cutting the pistons. When you add it all up, the total cost of Project 1003 came to about $4600.

If you’re entertaining thoughts of avoiding labor charges by doing this work yourself, listen up: Engine modifications of this magnitude are tasks neither for the inexperienced nor the poorly equipped. Just about anyone with a few common hand tools and a working forebrain can bolt on an exhaust system or change an ignition module; but few can handle—or should even attempt—jobs such as boring engine cases, fly-cutting pistons, or even changing cams and reassembling counterbalancers on Twin Cam Beta engines. If you intend to duplicate the modifications described here, have the work performed by expert mechanics with the proper equipment and the know-how to use it correctly.

But what about our original question: How smooth did the Beta remain after these big-inch, big-power modifications?

In terms of actual vibration, the Fat Boy didn’t change much at all. At lower rpm, it remained about as smooth as before; and at higher revs, it seemed to buzz just as lightly as it did when stock.

The key words here, however, are “actual vibration.” We could feel the engine more in its 100-horsepower state, but that feeling was not vibration caused by an imbalance of rotating and reciprocating engine internals; it was the effect of 12 additional cubic inches of combustion area producing a nearly 50-percent greater torque output and close to 60-percent more horsepower.

That’s a technical way of saying that each bang inside the combustion chambers is bigger and thus unleashes more energy. The vast majority of that energy is delivered to the rear wheel, but some of it finds its way to the rider through the grips, footrests, seat and tank. And since, with rare exception, riders are incapable of differentiating between shaking caused by imbalance and shaking caused by great, thunderous explosions in the engine, they perceive both as pretty much the same thing. But when you feel that increased vibration, all you have to do is close the throttle, which reduces the big bangs to little, tiny ones, and the engine smoothes right out.

So, all you owners of Twin Cam Betas, go ahead and hop up your motors to your hearts’ content. You probably would do so anyway, but now you at least know that if properly executed, the hot-rodding won’t ruin your new Softail’s smoothness.

But is it worth the expense? Judging by the smile on Bob Kimball’s face—which has been stuck there ever since he first rode his Fat Boy in modified form—we’d have to say yes. A hearty, resounding yes.