Bill Moorhead Custom Hardtail Chopper – New York Pork

Does the thought of partly cloudy skies and lows around 7 degrees above zero sound like the best weather for a nice, long ride? Probably not, but nevertheless these were the climatic conditions in Middleburg, NY, when Bill Moorhead and his friends left for Daytona Beach Bike Week in 2001.

Just like the renowned David Mann painting that illustrates a bike’s front wheel in the Florida sun and the rear wheel spinning in the northern snow, Bill and the boys rolled into town for a good time at Bike Week. Unfortunately, there’s a dark side to Daytona-in addition to all of the fun, it’s also a good place to have your bike stolen. Early in his Daytona Bike Week adventure, Bill walked outside to discover it had all turned bad, and his ’99 FXSTB Night Train was nothing but a memory.

They say every dark cloud has a silver lining. The airplane ride home provided Bill with an opportunity to ponder his next bike. Instead of rushing down to his local Harley dealer and buying a motorcycle with 100,000 clones, Bill decided he was going to build his next one. He blames watching the Discovery Channel’s Motorcycle Mania and the guy who sells chopper T-shirts at Wal-Mart for infecting him with the fabricating bug. Bill got so enthused that he converted the barn on his 100-acre dairy farm into a fully functional customizing shop.

Building the candy-apple-red bike you see featured here was not an overnight process. For the first three or four years, its Santee rigid frame hung bare from the rafters of the barn. This is not to say that Bill quit riding during that period or wasn’t adding to his tool collection. He bought a new Road King and scoured the countryside, looking for additional equipment.

In an old barn not far from his farm, Bill located a 60-year-old planishing hammer. The guy who sold it to him didn’t have any notion what the thing was, but Bill had a good idea. Originally, the device was designed to run down the quarter-panels of a car with body damage. Bill modified an existing set of dies and proceeded to teach himself how to make a motorcycle gas tank. Just as his friends had kidded him about the Santee frame remaining bare for so long, he took a razzing for his panel-beating skills. In the middle of Bill’s barn floor an impromptu pile of sheetmetal scraps began to rise up like a shrunken Christo sculpture. After blowing through three 4×8-foot sheets of 19-gauge steel, Bill completed his gas tank. Next on the list was the oil tank. By this time Bill had his metal-shaping skills dialed in, and the oil tank with internal oil filter consumed much less time in its creation. All of the welding on Bill’s bar-hopper (as he calls it) was done in-house (in-barn?) using a Thermodynamics TIG welder with a hand-held controller.

To handle steering, Bill bent up a set of custom handlebars that mount riserless onto the top triple-tree of a 2-inch-under Perse front-end. Instrumentation is provided by Dakota Digital gauges molded into a pod incorporated within the Arlen Ness-controlled candy-apple-red handlebars. The Perse lower tree features a super-clean bottom-mount headlight from Headwinds and a built-in 3-degree rake.

Bill explained to us that he built his bike on a budget but didn’t skimp when it came time to buy the parts he couldn’t make. He went on to say that Mike at Twin Tec in Catskill, NY, was his source for not only high-quality parts but also helped solve any tech problems he encountered. The high-quality route added many extra months to his completion time but was well worth the wait.

In addition to Arlen Ness hand controls, Bill preferred to use Arlen Ness wheels, brakes, and rotors. Avon tires bridge the low-profile gap between the polished billet Ness wheels and the asphalt below.

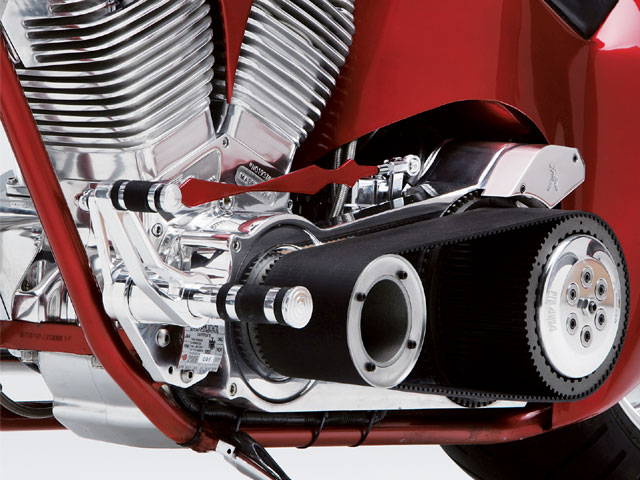

It’s interesting to note that Bill’s transmission was sourced from yet another person who left northern snow, only to have his bike ripped off in Daytona. Bert Baker’s state-of-the-art Baker Drivetrain facilities in Haslett, MI, manufactured Bill’s polished-billet six-speed transmission. To transfer power from the 121-inch TP Engineering Pro-Series motor to the Baker tranny, a Piranha Klutch from Karata Enterprises “bites back against slippage.” Bill was really pleased with the quality and high performance of his TP motor. After about 5,000 miles a year of bar-hopping and street-light Grand Prixs, the 121-inch TP motor runs and sounds brand-new.

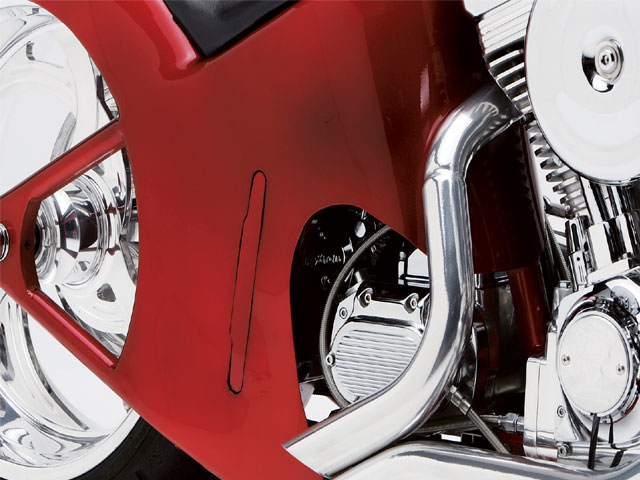

There’s more than meets the eye to Bill’s bodywork. After wrapping a sheetmetal doghouse continuous to the molded-in rear fender, he concealed a modified Dave Finn retractable license plate within the right-side panel. With the sheetmetal and frame work completed, Bill’s next task was to smear polyester body filler all over everything and sculpt it into shape with cheese graters and sandpaper. Once that had taken place, it was time to hose on the primer-not just any primer, but some real thick R-M goo from BASF. Making sure the final coats of primer were free from pits and deep scratches, Bill blasted on a CZZ-300 Carizzma candy-silver basecoat. Step two in the three-stage paint job was to evenly apply CZZ-400 candy-apple red utilizing the techniques Bill learned while painting his barn red with ferrous oxide. The last coat-but not the final step in the process-was a heavy coating of Carizzma clear, which was then allowed to set. Carrizzma clear sets hard and fast, so the next day Bill was back out in the barn with a galvanized milk bucket full of well water and a sheet of ultra-fine sandpaper, color-sanding his frame tank and fender. One of the final tasks was to pound out a seat pan, then send it out to M/C Seating for foam and upholstery.

Bill is a pretty talented guy. After he finished wheeling his bike out with 3-M compounds and polishes, he assembled his bar-hopper into the beauty you see gracing these pages.

Bill and his friends are still regulars at Daytona Bike Week, so if you spot his candy-apple-red bar-hopper, be sure to say hello-just make sure Bill is around and not up on a rooftop with his sniper rifle.