Induction System Basics – Hot Bike Tech

Here’s my buddy’s dual-carb 98ci kick-start Panhead, circa ’66. Then, times were simple and carburetion was clean-cut and unencumbered. A single bored-out carb or dual-carb setup did the trick. Foolishly, we didn’t worry about wearing out cylinders and rings by running air cleanerless. And to set history straight, we didn’t call them bobbers; they were choppers with a bobbed fender.

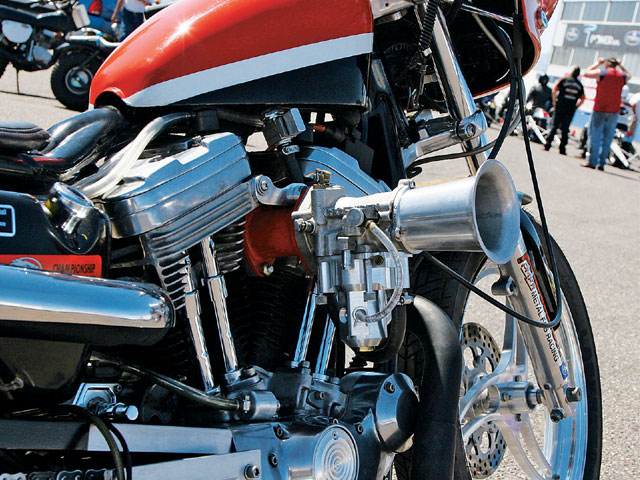

Here’s my 74ci XLCH, circa ’68, with bored-out Tillotson carb and velocity stack. Like my buddy’s dual-carb Pan, carburetion in the ’60s was clean and neat. Kick-start engines were “choked” by either installing a tickler in the float bowl or covering the open stack with your hand while kick-starting. The Tillotson was replaced soon after this photo was taken with the newly introduced S&S; carb.

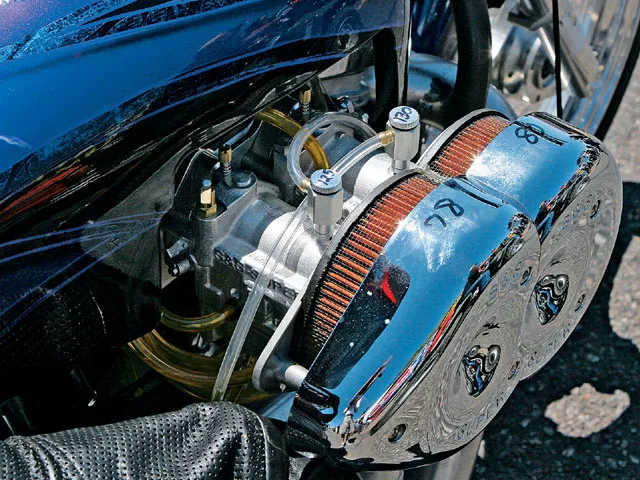

Stock V-Twin air cleaner assemblies are restrictive. Here’s a high-flow K&N-style; gauze and wire mesh a/c element that’s washable and re-chargeable. Also seen is a top-end breather kit that runs separate vent hoses from each head into the atmosphere.

S&S; Super carbs come with a nostalgic teardrop air cleaner housing. Be sure to install a high-flow air cleaner element.

Here’s a sano custom fabricated dual carb air cleaner made from two teardrop covers. Hidden behind the a/c elements are two S&S; Super D carbs feeding a big-inch racing engine. Each carb has a Thunderjet on top.

High-flow forward facing exposed element air cleaner kits are popular with some street riders and racers. This model includes a polished elbow leading to the EFI throttle body.

With proper modifications, the stock 40mm Keihin Constant Velocity carb offers excellent performance, throttle response, and fuel economy for mildly modified engines. CV carbs maintain high air velocity and fuel atomization over a wide range of throttle positions and can be bored out for increased airflow. – Courtesy Harley-Davidson.

Flat slide Mikuni carbs control airflow and air/fuel mixture with a rectangular slide that responds directly to throttle position. This Mikuni is set up with a tuned velocity stack for racing.

S&S; carbs are noted for high flow and are popular with street riders and racers alike. S&S; carbs are available in Super E, G, and D models. Shown is the Super D (largest of the three models) and customized teardrop air cleaner assembly.

Dual carb setups are useful on big-inch engines and great for show. Shown are dual Mikunis attached to a Rivera manifold and high-flowing washable re-chargeable air cleaner.

Various jet kits are available for the Keihin 40mm CV carb. Shown is the Yost performance Products kit, which includes needles, emulsion tube, jets, slide spring and drills.

Behind the classic teardrop air cleaner is an S&S; Shorty carb. S&S; introduced the Shorty version of their popular carb so that it would tightly tuck in under the fuel tank and not interfere with the rider’s leg. Since S&S;’ Shorty is about 1-1/2 inches shorter than their B or D carbs, it provides different tuning for the intake tract.

Various length manifold spacer blocks are available for fine-tuning the engine’s intake tract. These are from Yost Performance Products.

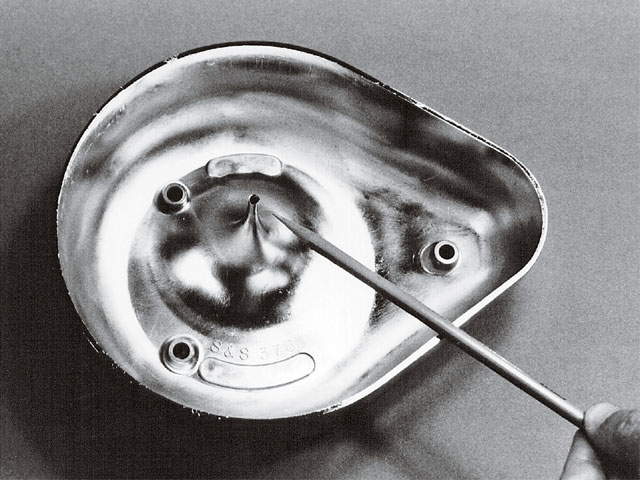

S&S;’ air cleaner backing plate has a radiused entry way leading to the carb’s throat and an air-directional cone on the inside of the tear drop cover. This design improves flow by smoothing the air while directing it into the carb’s throat.

S&S;’ air cleaner backing plate has a radiused entry way leading to the carb’s throat and an air-directional cone on the inside of the tear drop cover. This design improves flow by smoothing the air while directing it into the carb’s throat.

A velocity stack is used to smooth the flow of air into the carb’s throat and help tune the intake tract length to the desired power band.

In the last Motor Series installment, we finished a two-part series on the valvetrain, concluding with pushrods, rocker arms, and the valve spring package. This month, we’ll turn our attention to the induction system. In the good old days, induction systems were rather simple: one or two Linkert carbs, maybe a polished velocity stack, maybe not, and we were good to go. Maybe that wasn’t the best combination for performance, but at the time, we thought it was. Today, induction principles are the same but more complex if you have electronic fuel injection (EFI). As you probably know, the Factory switched over to EFI for all 2008 models. Like it or not, just as Evos have taken a backseat to Twin Cams, the venerable carburetor is subtly being relegated to backseat status. Nevertheless, carburetion has its place and will persevere. You dance with the one who brought you, so we will talk a bit about both EFI and carburetion.

Regardless of whether your engine is fuel-injected or carbureted, the important principles remain the same. If you think of your engine as an air pump, performance gains can be realized by moving more air through the engine. The induction system refers to the system of components that move air and fuel into the cylinders. The system begins with the air cleaner and ends at the intake valve in the port. Sandwiched between the air cleaner and intake valve are various components, depending on whether the system is carbureted or fuel injected. The induction system’s passageway for moving air and fuel is called the intake tract.

With a carbureted engine, the induction system consists of the air cleaner, carburetor, intake manifold, and cylinder heads. The carburetor mechanically manages both air and fuel flow. In contrast, an electronic fuel injection system includes an air cleaner, throttle body (TB) for controlling airflow, fuel injectors for metering fuel, intake manifold, processor called an Electronic Control Module (ECM), and several sensors that feed information to the ECM. The ECM calculates the correct amount of fuel required for a given engine rpm and engine load, and determines the precise moment at which the fuel injectors release the fuel into the intake tract. Fuel injectors are typically located in either the intake manifold or intake port, although some are fitted into the cylinder head to spray fuel directly into the combustion chamber.

In stock trim, the Big Twin engine is severely airflow limited. Increasing airflow through the engine will increase power as long as the quality of the air/fuel mixture and combustion process are not degraded. The air cleaner and exhaust system are typical starting points for increasing airflow, because both are highly restrictive and easy-to-replace bolt-on parts. Additionally, the late-model Keihin 40mm constant velocity (CV) carburetor is another bolt-on induction part easily replaced, but it is not a major airflow bottleneck until engine displacement is increased. Other major components that increase engine airflow are the camshaft(s), cylinder heads, and larger displacement through boring, stroking, or a combination of both. However, these parts require internal engine modifications, and only the cylinder heads are considered part of the induction system. By the way, we discussed cylinder head science in the Vol. 39, No. 8 issue of HOT BIKE.

Carbureted Engines

For carbureted engines, replacing the stock air cleaner with a free-flowing unit is an easy way to increase airflow and performance. Various low-restriction aftermarket air cleaners’ assemblies are available that easily bolt on to a stock CV carburetor. The job of a performance air cleaner is two-fold: 1) remove contaminants in the air to protect the engine and 2) flow sufficient air for maximum power. Air cleaners vary widely in performance based on design, size, and filter material. Over the years, the K&N-style; filter element has proved to be an excellent design that satisfies both requirements. K&N; elements use a pleated gauze material wrapped in wire mesh. The pleated design provides a large surface area for high airflow, while the gauze material-when treated with the proper type of oil-does an excellent job of trapping harmful particles that can scratch cylinder walls, piston rings, and valve seats. K&N-style; filter elements are washable and rechargable with oil for maintaining optimum flow and filtration.

Increased airflow requires richer carburetor jetting for the additional air. In fact, the stock CV’s jetting is too lean, and a performance increase can usually be realized by making jetting modifications while using even a stock air cleaner. As such, always be sure to re-tune your carburetor after installing a high-flow air cleaner. Additionally, regardless of the filter system you buy, make sure that it includes the proper features for connection of any engine breather hoses.

The stock Keihin 40mm CV carburetor that shipped with some Evo and Twin Cam engines is an excellent carb, providing decent performance for mildly modified engines, along with excellent throttle response and fuel economy. However, to realize optimum performance, the carb must be rejetted. Various jet kits are available that include a selection of low and high-speed jets, tapered jet needles, and instructions for many engine combinations.

Although the stock 40mm CV is an excellent carburetor, it has flow limitations. High-revving and large displacement Evo Big Twin and Twin Cam engines can benefit from a higher-flowing carburetor. A carburetor operates by responding to differences between atmospheric pressure and the reduced pressure created by a venturi in the carb’s throat. Certain minimum air velocities must be maintained through the carb to achieve optimized air/fuel mixture and fuel atomization for maximum power. Selecting the correct size carb for the application will allow proper intake tract velocities for optimum performance, while an excessively large carb will result in erratic fuel metering, poor fuel atomization, and reduced power and throttle response.

To increase airflow, you have the option of either modifying the stock 40mm CV carb or installing a larger aftermarket carburetor. Trock Cycle and Wood Performance offer various stages of modifications for the CV carb that increase flow and improve throttle response. Harley-Davidson Screamin’ Eagle also offers high-flowing 44mm and 51mm CV carbs.

Other high-flowing carbs are available, including the popular S&S; and Mikuni. S&S; offers butterfly-style Super E, G, and D versions of their carb, while Mikuni has flat slide 42mm, 45mm and 48mm carburetors. Whereas the stock 40mm CV carb maintains airflow velocity and atomization at a constant level using a throttle plate and vacuum slide, S&S; carbs use a butterfly (round throttle plate) and Mikunis use a flat rectangular slide that respond directly to throttle position. Optimum carb size is based on engine displacement, rpm, engine combination, and application. But each carb’s performance range can overlap the range of a different size carb, so rider priorities can affect the final decision on carb model and size. Nevertheless, some broad guidelines can be established for carb sizing, but remember that engine displacement alone is not the only determining factor for optimum performance.

As a general rule, the S&S; Super E and Mikuni 42mm carbs are popular for stock displacement Evo and Twin Cam engines up to approximately 95ci, while the S&S; Super G and Mikuni 45mm are best for roughly 95ci and larger engines. Super G carbs can be bored out for additional airflow and various main discharge tubes are available to suit an engine’s airflow demands. The Mikuni 48mm Flat slide is best suited for engines in the 107ci to 113ci range and larger. The S&S; Super “D” carb is available in two venturi sizes and is sometimes bored out for increased flow. Since the D is designed as a racing carb and does not include an accelerator pump, it is mostly used on large-displacement, high-revving race engines, although some Ds are seen on 113ci to 120ci and larger hot street engines. The Harley-Davidson Screamin’ Eagle 51mm CV carb works well with 120ci and larger engines and high-revving smaller engines. As an alternative to using one large carburetor, some engine builders prefer two smaller size carbs for better throttle response and increased total airflow. However, an efficient intake manifold is important for realizing performance gains.

Some aftermarket carburetors include a performance intake manifold while others use a stock manifold. In some cases, a performance manifold can improve performance, but there is no guarantee. Dyno or track testing is the only way to know for sure. I recommend consulting with a knowledgeable engine builder for the optimum combination. On a related topic, when having your cylinder heads ported, always include the intake manifold so it is matched to the intake port and optimized for flow. Moreover, keep in mind that a manifold with the largest plenum volume is not necessarily the best performer, but the manifold should provide a smooth transition from the carb to the port without any abrupt drop-off.

Tuning Considerations

The stock 40mm Keihin CV carburetor is excellent for mild hop-ups on 80 to 88ci engines and even some 95ci engines as long as the carb is rejetted and tuned properly. Rejetting the CV carb will eliminate any low and midrange staggering and coughing while allowing the engine to develop to its maximum power potential.

There are a couple methods for rejetting the Keihin CV carb. Some engine builders prefer a complete jetting kit while others prefer their own mix of individual parts. Certain jet kits are too rich for optimum performance and fuel efficiency. As an alternative to a complete kit, you can replace the CV’s needle jet and possibly the slow-speed jet, then adjust the idle mixture jet and you’re good to go. If you want to go a step further, you can have a qualified shop modify the throttle bore for greater airflow. The 40mm Keihin CV carb gives excellent low speed response and, if set up properly, provides decent power and excellent fuel economy on pump gas.

For optimized power, airflow through the induction system should be as laminar as possible. Keeping airflow as straight as possible while minimizing intake tract turns will minimize turbulence and restrictions while optimizing flow and velocity. To this end, use a large high-flowing air filter element, which will help straighten the airflow into the carb’s throat. Additionally, some air cleaner backing plates include a radiused inlet to reduce turbulence for improved airflow.

When testing intake manifolds, the most important tuning elements are tract length, tract taper, and plenum volume. Larger volume manifolds may perform better at higher rpm but usually provide slower throttle response. When experimenting with different manifold volumes, start testing using the manifold having the smallest volume and increase volume until no performance gain is realized.

Intake runner length can be used to tune an engine based on pressure waves or sound. The shorter the runner length, the higher the engine rpm in which the tuning effect will take place. Runner length is measured from the carb entrance to the valve seat. The length of the intake manifold, carb spacer, carb body and velocity stack or radius ring will vary runner length and change the point of peak horsepower and peak torque. Knowledgeable engine builders use intake tract components as “tuning” tools to shift the engine’s power band either lower or higher, help diminish reversion pulses, stabilize the air/fuel mixture, and improve the combustion process.

In this Motor Series installment we covered the induction system for carbureted engines. Next month we will conclude the induction system with a discussion about electronic fuel injected engines.