KC Creations Custom Softail Chopper

Back in the ’60s, the idea of driving a tricked-out car was just as appealing as it is today. A stock, direct-from-the-factory automobile just didn’t cut it for many, despite the availability of cars with huge-cubic-inch motors and options lists that went on forever. Some owners wanted their cars chopped, lightened, lowered, and painted to create a feeling that transcended mere metal machinery. Oftentimes, enjoyment, power, and agility were chosen over practicality or a smooth ride. Open-cockpit roadsters, coupes, and sedans competed against each other on the streets and dragstrips of America.

Drag racing was a rite of passage for lots of teenagers during the power wars of the ’60s, when Detroit upped the ante year after year with bigger motors. Not only was it fun, it was a social environment that brought people together to build and work on cars to see who was the fastest in town. Dwane Smith remembers his days of cruising in style while ripping up the tarmac in modified custom cars. He wanted to re-create some of that feeling, but-decades later-this time on two wheels.

Living outside Kansas City, KS, Dwane had heard all about the custom motorcycles that Kim Suter was designing and building out of his KC Creations shop. Dwane took a short drive over to the Overland Park, KS, shop to discuss his ideas for a new dragster/roadster-inspired ground-up custom bike. He didn’t want his bike bolted together with parts off the wall, but instead sought a bike with flowing, hand-formed metalwork topped with a unique paint scheme. Of course, being true to his roots, it had to be fast.

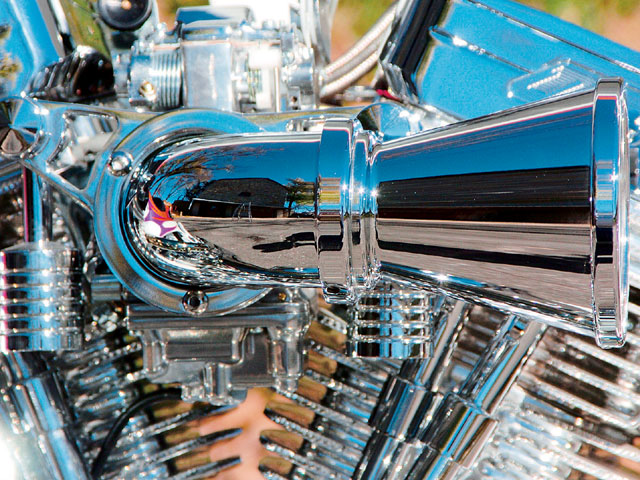

With that in mind, the powerplant was the first thing decided upon. Dwane wanted big, and he wanted it made in the U. S. of A. Kim looked no further than TP Engineering to put together a motor package that could smoke the competition. Just about every component in the 124ci motor was manufactured by TP-cases, barrels, pistons, rods, flywheels, rockers, rocker boxes, and cam. Accenting the motor is a Wimmer velocity stack that attaches to the polished Mikuni carburetor. For some added bling, the cylinder fins were diamond cut, which increases fin surface area as well as reflecting light.

With a motor chosen, Kim’s next task was building a frame for it. Based on Dwane’s desire to have a fast boulevard scorcher, Kim decided on long and low for the chassis. It would look good and be able to keep the front tire on the ground more easily when the throttle was whacked. A curved backbone and downtube were welded to a neck tube with a final 43-degree rake that would be joined to a curved KC Creations Softail-style radius swingarm. This would only be the beginning, as the frame was extensively molded for both pure aesthetics (such as the downtube) and to create a seamless transition between the tubing and the sheetmetal to come.

Before starting on the sheetmetal, a set of 4-degree KC triple-trees holding 14-inch-over fork tubes was bolted to the neck of the frame. A six-spoke Weld Racing wheel wrapped in Metzeler rubber was torqued down before attending to the rear suspension duties. The swingarm, holding a matching Weld wheel with 280 tire, was shored up with a hidden, horizontally mounted Legend Air suspension. With much of the chassis together, Kim was able to use the contours of the wheels to start working on the fenders.

A close-fitting, caf-style Russ Wernimont fender was used up front to cover the 21-inch tire. The rear fender would prove to be more difficult to fit, as Kim wanted it to seamlessly blend into the seat-pan area and side panels covering the oil tank. He also frenched in the license plate to avoid using any unsightly brackets for the tag. Along the same blending lines, Kim made a gas tank that fit into the backbone like a missing puzzle piece, mating up with the molded area that extends from the rear fender. At first glance, it appears that all the bodywork on the bike is one unit.

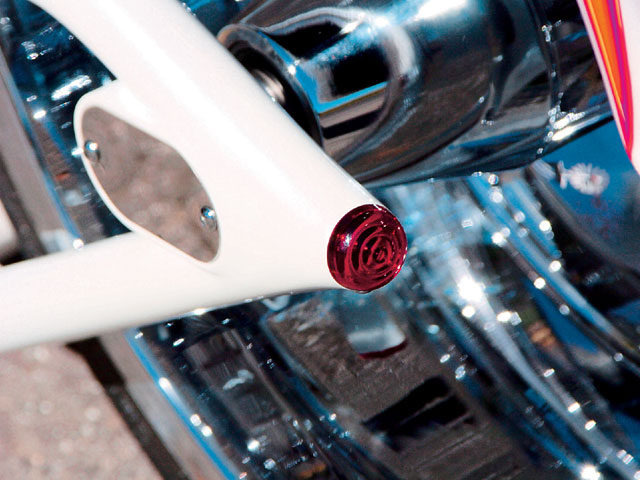

Once mockup of the parts was complete, it all came apart for the frame and metal to be painted. Scott Thomas of KC Creations laid down a pearl-white Diamond Ice base coat, followed by a combination of Pearl Goldmine and Pearl Passion Purple for graphic accents. In addition, the tops of the fenders and tank feature hand-drawn pinstripes in a style popularized in the ’60s. After the paint dried, the TP mill was bolted into place and connected to a Baker right-side-drive, six-speed transmission via an H-D chain primary. A secondary belt connects the tranny to a combination pulley and drive-side brake rotor on the rear wheel, which cleans up the left side of the bike. Keeping with the clean look of the bike, Climax handlebars with integral risers and hand controls with a single Dakota Digital gauge in the center were used. A Headwinds light was perched above the bottom triple-tree to provide the only light up front, while a unique set of taillights/turn signals was placed within the rear of the swingarm, aft of the rear axle. Two finishing touches would complete the bike: a seat made by Danny Gray and a set of Martin Bros. stepped exhaust pipes.

Kim and the KC Creations crew listened to what Dwane wanted in his ride-a bike that reminded him of his past hot rod days. The stance, power, and grace of this machine, combined with the subtle graphics, hit the mark. If you’re ever in the Kansas City area and you see a white blur blow your doors off, it may very well be Dwane cruising on his custom KC bike.