Primo Brute III

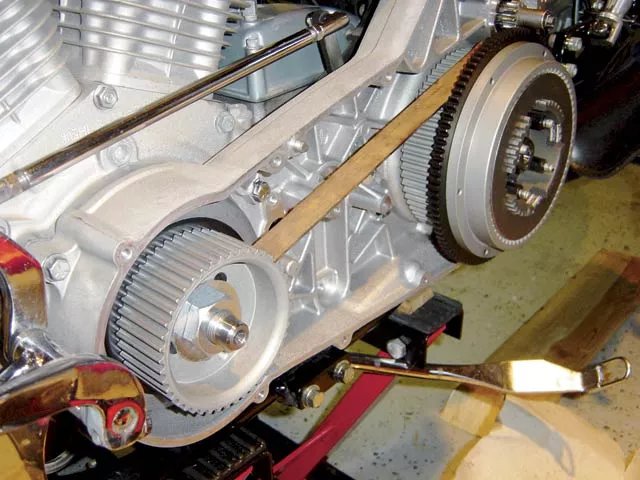

1. Here is Primo’s Brute III Enclosed Belt Drive kit for a Dyna. Included are hard-anodized pulleys, a 1-inch Aramid reinforced belt, a dry clutch, a replacement transmission shaft bearing, and all the hardware and instructions. I also opted for the vented covers and picked up a JIMS bearing removal/installation tool (not shown).

2. I began by draining the primary case (the last time I’ll ever do that!). I used my Sears Motorcycle/ATV Jack to lift the bike for easier access. I secured it with tie-down straps. If you don’t have a lift, why are you waiting? I removed the derby and inspection covers and the primary cover.

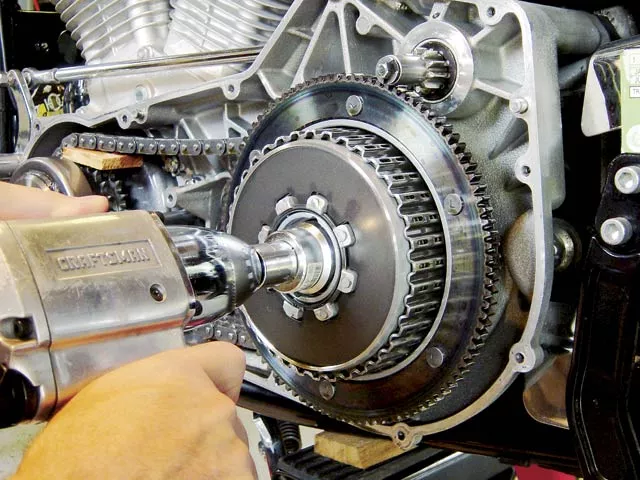

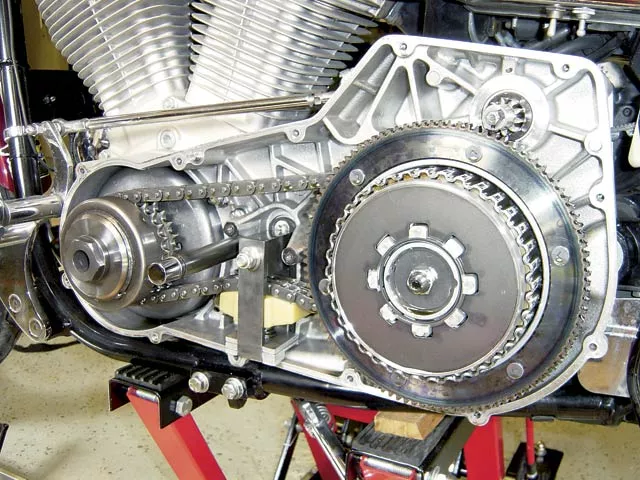

3. I removed all the stock chaindrive components. You’ll need large sockets, a 1-inch for the main, and a 1-inch for the transmission shaft nuts. An impact wrench makes the job quicker. I wedged a wooden block between the sprockets of the main shaft and the chain to keep the driveline from rotating while breaking loose the nuts. Remember the transmission nut has left-hand threads.

4. I cleaned the inner and outer covers to remove all the primary fluid. If you’re going to use the OEM transmission two-piece bearing, then you can now lubricate and inspect it and go on to the dry clutch and belt installation in step seven.

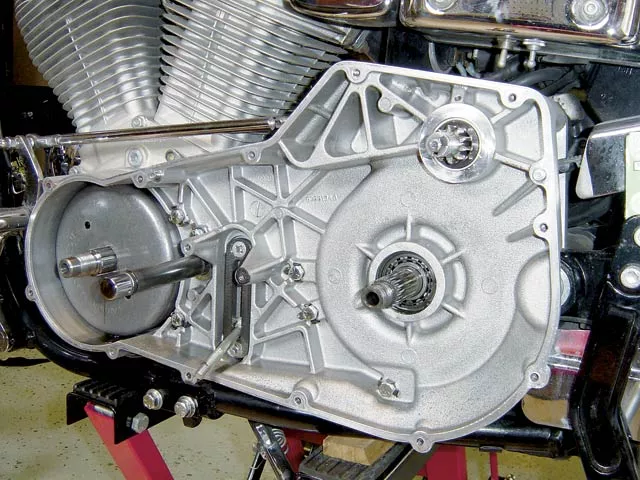

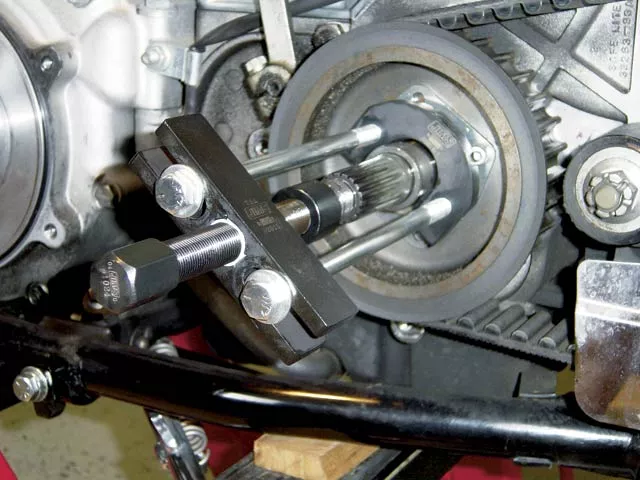

5. Since I replaced the OEM bearing with the Primo-supplied sealed bearing and also wanted to remove the stock foot-shifter shaft (not needed with new forward controls), I removed the inner primary case. That makes it easier to use the JIMS tool to pull the bearing race. I slipped the puller behind the race and tightened the bolt. I tapped the race with a hammer and easily slid off the shaft.

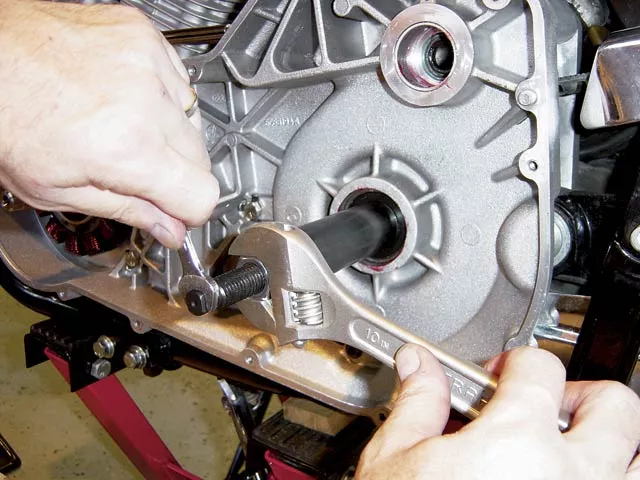

6. I reinstalled the inner primary case. I torqued the bolts as specified. For clearance on a Dyna install, replace one of the OEM bolts with the Primo supplied hex head bolt as directed. I used the JIMS tool to press the new sealed bearing onto the shaft.

7. I installed the front and rear pulleys without the belt and checked for alignment with a straight edge. Use shims on the front pulley as needed for satisfactory alignment. This is a good time to check for any clearance problems with the inner primary. I removed both pulleys.

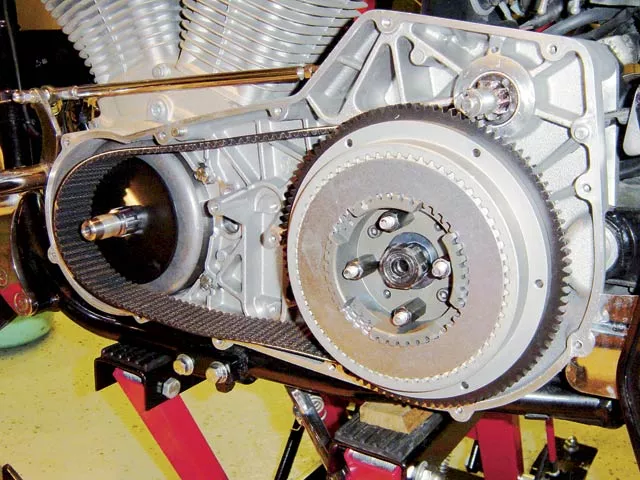

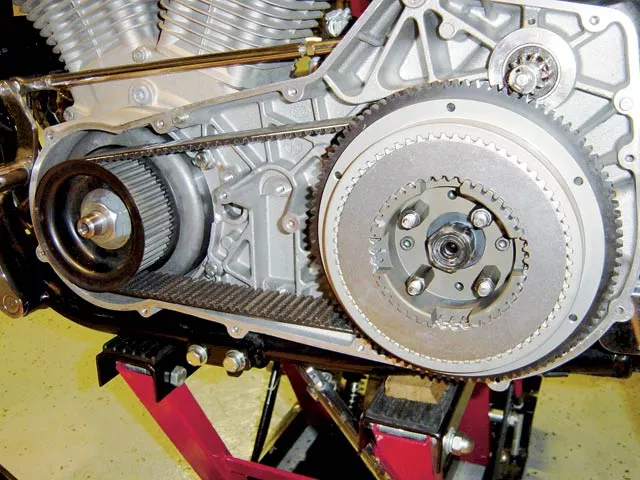

8. I installed the rear pulley with belt and dry clutch. The clutch came from Primo with all plates installed and adjusted. No further adjustment was required. I torqued the transmission nut to spec.

9. Because the belt is very tight, to install the front pulley, I inserted it on the main shaft, aligned the spines, then used the main nut to carefully slip the pulley onto the shaft. Once fully engaged, I added washers and torqued to spec. Check the belt tension per the Primo instructions.

10. I checked the primary outer cover for clearance. Shown here are my initial cut marks. It turns out that I had to remove most of the fins and other high points on the outer cover. I used modeling clay to find the last touch points. I flushed out all metal shavings.

11. Heat is the enemy of beltdrives, so in addition to the vented covers, I added washers between the primary cover and the inner case to create an air gap. After making a final inspection, I torqued the outer cover bolts, and was ready to roll. Another bonus is that I don’t need any more primary gaskets!

12. Here’s the OEM chaindrive and wet clutch before replacement.

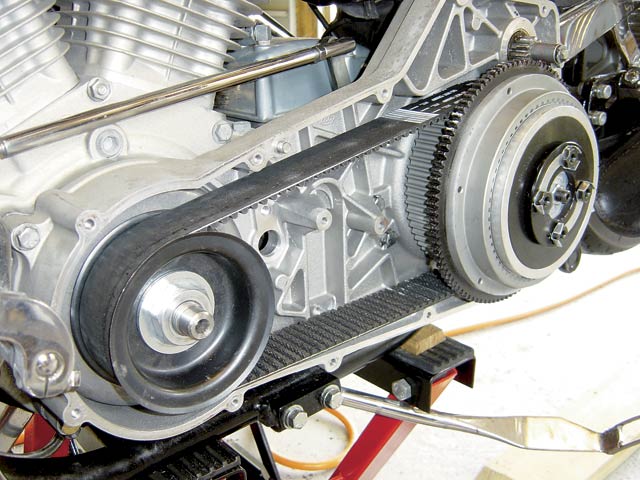

13. Here’s the new beltdrive and dry clutch after installation. I’m completely satisfied: stealth belt drive, cleaner, quieter, no fluid, and the clutch lever takes less pull.

One mental obstacle to installing any major upgrade is the reluctance to remove parts, especially drivetrain stuff. When you have to remove those parts to fix a broken one, then a little voice says, “While I’ve got that stuff off, why don’t I…” That’s what happened to me when I burned out my alternator while jumpstarting my bike off a truck. Bad idea, but later when I realized that I’d have to remove most of the drivetrain on my ’95 Dyna Super Glide just to replace the alternator, I figured it would be a good time to upgrade to a beltdrive.

Why beltdrives? Besides the basic “I want something different from what I’ve got” urge, I have disliked chains since owning a KZ-400 in 1976. So I welcomed a chance to eliminate it and say goodbye to a wet clutch, a leaky primary, and fluid draining. Plus, I like the stealthy look of the enclosed belt. The casual observer may wonder how you’re retaining primary fluid through those vents.