Redneck Engineering’s Custom Chopper

If you’ve been around for a while, you’ve undoubtedly heard the stories about the boys from Redneck Engineering (RE). We’re going to leave the long tales about the men behind Redneck for the campfire or road trip, but legend has it that some of the yarns are even true. While you’ll discover that these guys are technologically savvy, their crusade and success-so to speak-has been carried by hardtails. Rigids, kidney-busters, old-school-whatever you want to call them, they epitomize the core essence of American V-Twin motorcycles. Not made for the timid, these stripped-down scoots with no rear suspension (although some do call a slightly underinflated rear tire a shock absorber) are light and fast bikes.

Current preferences and styles leaning toward retro and cutdown have provided a renaissance for the hardtail frame. Redneck saw such business from its hardtail frames that the guys there couldn’t think of much anything else. At every show the crew attended, they’d get asked when they were going to build a bike with a suspension-Redneck-style. Demand was so high for the company’s rigids, it was hard to keep up with orders; they were often six to eight months behind production as it was. With expansion (Redneck has about 20 employees) and hard work, the crew got caught up, giving head frame guru Nobody a chance to think outside the box. There’s no doubt that shockless scoots are mean-looking machines; even Harley Davidson saw that more than 20 years ago, achieving its largest success producing bikes that resemble the machines of times past. Of course we’re talking about the Softail, with horizontally mounted shocks hidden under the frame. They were a big departure from the two traditional vertically mounted shocks found on rides for more than half a century.

Not wanting to merely duplicate what was already widely available in the aftermarket, Nobody got to thinking about his version of a Softail-style frame design. He wasn’t just pondering the project; the redneck from South Carolina is also an expert in CAD (computer-aided design), engineering, and computers in general. Firing up his Sideworks program, Nobody came up with the look and geometry that would make a superior visual and great-handling chassis. He finally decided on two rear suspension designs-the first with shocks arranged much like the OEM H-D style and another with an exposed monoshock. All of this work was for the customer, as Nobody himself thinks everyone should ride rigids.

In fact, Redneck refers to the new rear suspension frames as “FCA” (For Candy Asses), “FCA-MS” (the monoshock version), and “FCA-HS” (hidden shock). Getting the shock to look right, operate optimally, and exceed Redneck’s high handling standards was no easy feat-but more on that later.

Both FCA frames are generally based on Redneck’s successful rigid frame, “Curves,” and are similar in profile to the company’s “Screw This” bike. The frame features a curved backbone that not only looks good but also was designed specifically to clear the rocker boxes and the starter in one flowing, continuous arc from neck to downtubes. But this new FCA frame wasn’t about just cutting off the hardtail section and adding a swingarm. On this particular build (you can get it with any dimensions you want), the guys at Redneck stretched the single downtube 5 inches up while giving the backbone a 5-inch extension, both culminating at a 46-degree neck. The curved backbone flows around the starter and transmission before meeting the framerails. A dual-tube swingarm (a narrowed-down version of the Curves tailsection) was added to a pivot in the frame, allowing wheel movement for the suspension. Everything needed to hold the rest of the parts for the bike together was welded to the frame, including the tranny and motor mounts, attachment points for the oil tank, rear fender, shock, seat, and under-tranny battery box. About the only finishing touches to the frame were smoothing out the welds a bit.

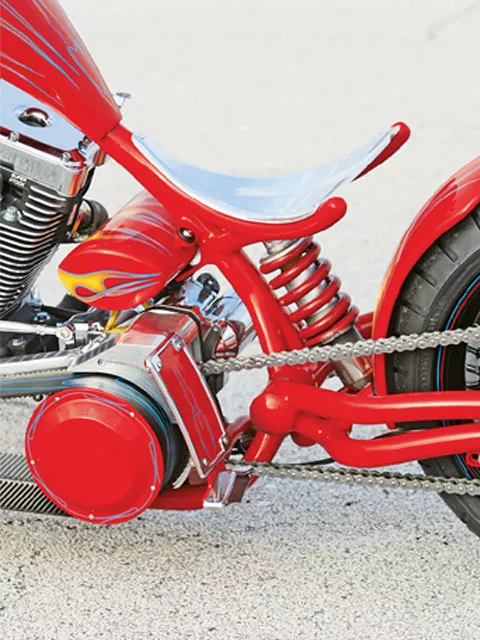

Getting the suspension to ride the best it could was not an easy job. It’s not as simple as just bolting a shock between the frame and the swingarm. Length and angle, spring and rebound rates had to be carefully thought out. Nobody enlisted two prominent shock manufacturers, Works Performance and Progressive Suspension, to lend a design hand to get the monoshock operationally perfect. Based on the weight distribution and leverage of the single shock absorber, the spring rate had to be experimented with to get it just right. According to Nobody, the suspension is so good there’s no need for a plush seat. To prove his point, he rides the bike with the aluminum seat you see here-no cushion. It was made that way on purpose. Up front an RE Springer frontend of undetermined length was bolted on. Nobody says his frontends are “built to work” and don’t use the “inches of stretch” convention. Any way you look at them, they are long. We’ll leave it at that.

The crew’s choice of minimal sheetmetal highlights the frame, along with every component of the bike. An RE gas tank matching the backbone contour sits high above the top tubes, while a custom-made elliptical oil tank that’s bolted to the frame sits behind the motor. Only one fender, the rear, was used-a sleek, short unit to cover the meaty-but not bloated-Avon 250 rubber. Gary Strait sprayed all of the sheetmetal as well as the frame with multiple coats of brilliant Porsche red paint. In addition, Gary and Charlie Tyree laid down some tasty flames and pinstripes in yellow with blue tinting.

Overall the look of this bike is airy, with lots of open space. The 96-cubic-inch S&S; Evo mated to the six-speed Roadmax gear banger looks almost naked, it stands out so much. Tight-fitting, short dragpipes and an open-element velocity stack don’t detract from the motor or the right side of the bike. Every part of the machine is accessible, either to look at or service. Whether in a barn in SC, a garage, or the side of the road, there’s nothing like being able to wrench with ease when the need arises. Keeping with the open theme, a set of 60-spoke DNA wheels was added that feature black powdercoated rims and hubs. Both rims were pinstriped to complement the rest of the bike’s color scheme. A drive-side DNA sprotor, clamped by an HHI caliper, links the chain to the tranny output. No-frills black PM controls are used for both hands and feet.

We had a front-row ticket to the first FCA-MS model the Redneck wrenches built in their Liberty, SC, fabrication facility. Many have undoubtedly seen Nobody flying down the tarmac on the company’s first Softail, as Redneck’s bikes are designed to be ridden hard. Keep your eyes peeled around the rallies this year, as well as all points in between. For all those who asked, Redneck has entered the building.