From Wild to Mild

The bike was rolled onto the lift and secured with a set of tie-downs. Arman started by draining the primary fluid, then removing the outer cover. He then removed the chain adjuster and pulled off the front pulley and the clutch basket.

Next, all the inner bolts were removed along with the two starter bolts on the back of the inner primary. Arman then removed the primary.

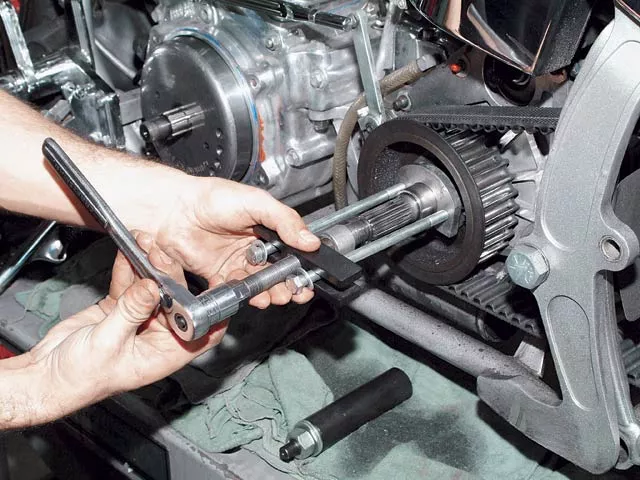

Before the new primary support plate could go on, the inner race needed to come off so that the pulley would sit flat against the trans and line up with the motor.

A new oil seal was installed on the crankshaft before the support plate was installed.

To see which belt would look best on our ’99 custom, we started with the 7-inch monster. First, the support plate was placed on the bike.

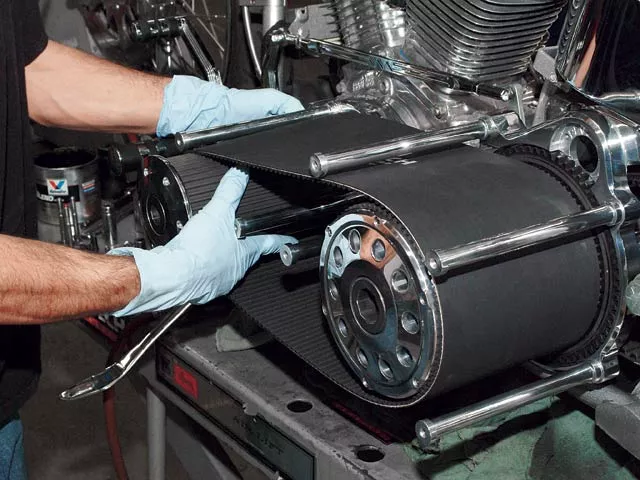

The belt was then slid onto the pulleys as a mock-up just to see how it would look.

Here you can see just how wide the belt looks at 7 inches wide. It looks like a treadmill for a small animal.

The next size that Arman placed on the bike was the 6-inch-wide belt and the Demon cover. It looked good but was still too wide for this bike.

Well, we had to try the 5-inch belt with the Poison cover, but it was still too big. One cool thing about Hitech beltdrives is that all the covers have the same bolt pattern, so the size of the belt does not matter.

This kit comes with everything you need, including both pulleys, a belt, clutches and spring, pulley covers, a bearing support plate and a backing support plate, and a starter cover.

First, Arman bolted the backing plate onto the bike using the eight bolts in the kit with a little thread locker.

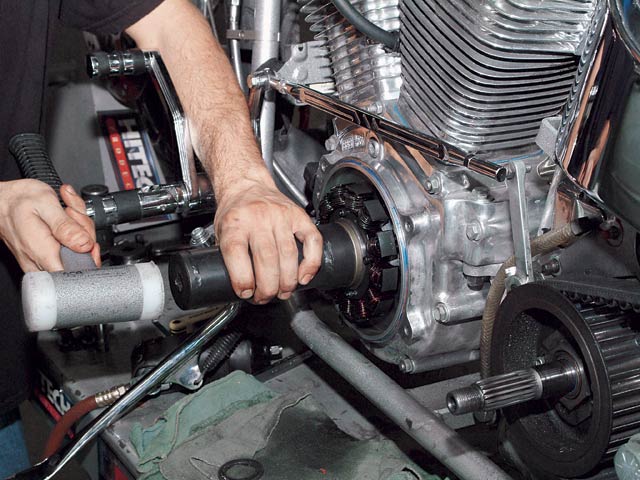

Next, the pulleys were installed with a little grease inside the pulley, and the clutch nut was torqued to 70 lb-ft.

The clutch plates were then installed — steel plate first, ending with a friction plate.

The presser plate was installed next; there are marks on both the pulley and the presser plate that needed to be lined up when installed.

Next, the clutch springs were installed. We started out with the 56-pound ones. In the kit, there are three sets — 56-pound gold, 82-pound green, 100-pound red — to custom fit your bike and keep the clutch from slipping.

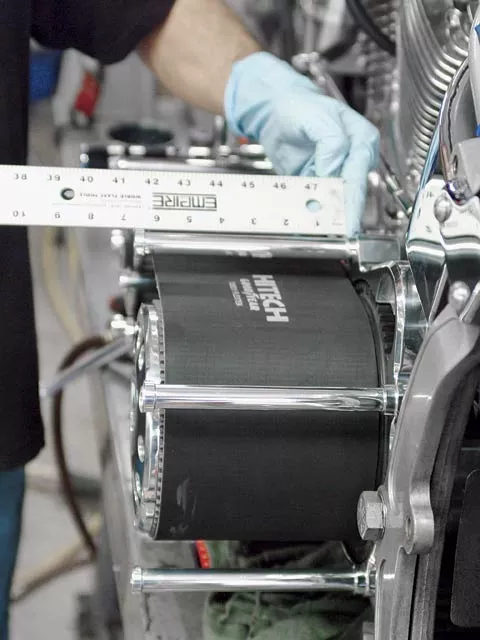

With both pulleys bolted in place, Arman used a straight edge to check that both were aligned. He found that the front pulley needed to be shimmed out 1/8 inch.

After the pulley was aligned, he torqued it to 90 lb-ft.

The belt was then slid onto the pulleys. The support plate is CNC’d to an exact spec so that each belt fits perfectly.

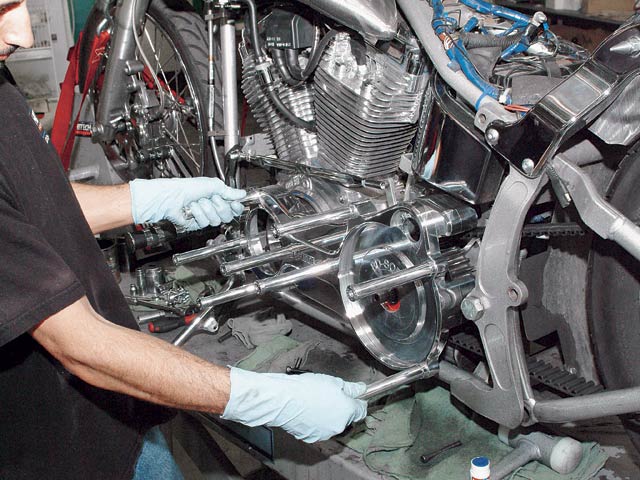

The starter shaft was then installed. A dab of grease was placed on the pinion shaft.

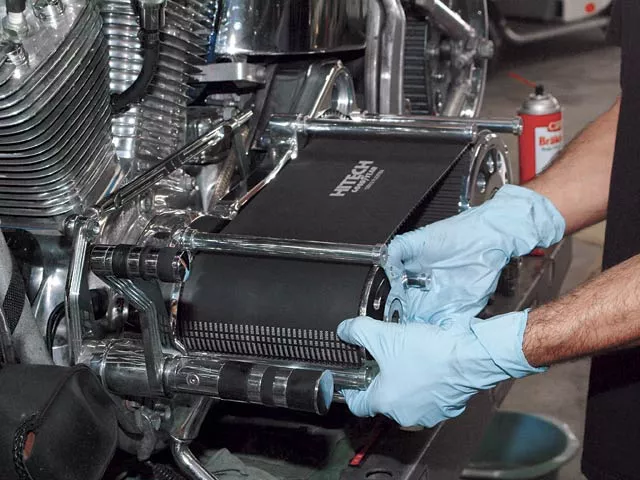

The cover was then bolted to the support plate.

The clutch was adjusted before the cover was placed on the pulley.

The cover was then bolted to the rear pulley.

Next, Arman placed the cover on the front pulley, along with the inner belt stopper. This keeps the belt from creeping off the pulley.

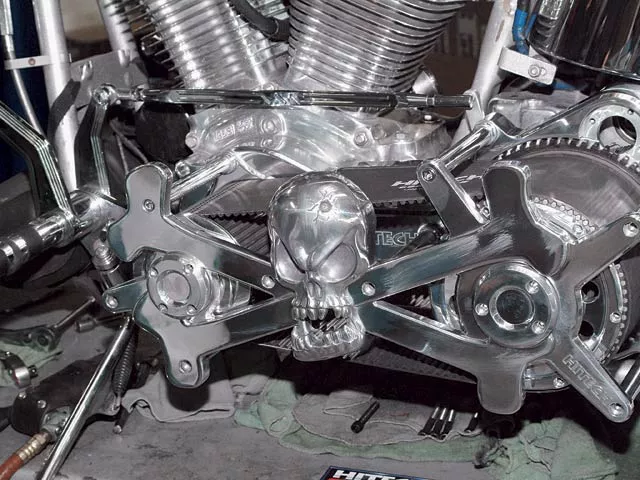

After trying all the different sizes, we went with the 4-inch beltdrive along with a less flashy cover: the Dominator.

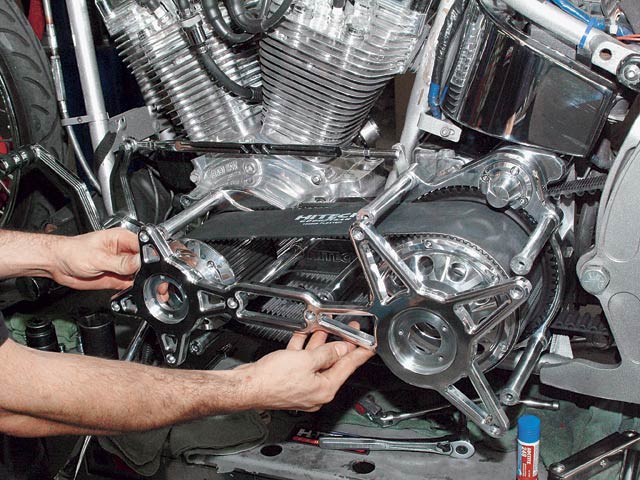

The outer cover (bearing support) was placed on the beltdrive next.

There are six bolts that hold the outer cover in place, along with some thread-locker. Arman torqued each bolt to 40 lb-ft.

The last step was to bolt the bearing covers to the cover.

Here is a look at the beltdrive from the side. You can see just how wide it is. As the bike was running, we were surprised just how well the new belt sysem sounded.

In the end, this is how the bike looked with the new beltdrive. It has a completely different look. While it is a bike for the everyday rider, it has the custom look of a show bike.

When you think of LED’s, you don’t think of beltdrives, but that is just what happens when you call Hitech in Canoga Park, California. Not only do these guys have some of the coolest LED products out for both cars and bikes, they also carry a full line of beltdrives to fit all tastes and sizes, from 3- to 7-inch-wide belts. They have all the extras you may need, as well as any size offset kits to align the motor and trans, and keep the rear wheel straight. To add to the different styles of every bike out there, the company also has a full line of changeable outer covers. We showed up with our ’99 Softail to show how different the bike could look by changing out the old enclosed primary to a wide-open beltdrive with a flashy cover plate or a tame cover plate. Hitech was inundated by telephone calls and emails from existing customers all over the world, as well as a new base of customers who were not only interested in its own outer bearing supported 4-, 5-, 6- and 7-inch Monster units, but also in upgrading their BDL, Karata, and Billet-4-U units with Hitech covers.

Arman Akserelian was glad to show us the how-to’s with the Hitech products. He wasted no time to get this job done and get us back on the road.