Zipper Performance Products – First Look

The ThunderMax Marelli EFI conversion kit contains the ThunderJet EFI throttle body and manifold, ThunderMax EFI control unit, pressure-regulator manifold, ThunderJet air-cleaner backing plate with manifold air-temp (MAT) sensor and Hi-Flow air cleaner and cover, ThunderMax tuning software with cable and miscellaneous wires, relay, clamps, and hardware.

The ThunderMax Auto-Tune Module works with your pre-’07 ThunderMax EFI controller to create a wide-band closed-loop EFI system. The ThunderMax Auto-Tune processes feedback from two wide-band oxygen sensors to adjust the fuel volume at all rpm and throttle positions. These sensors continually provide feedback for corrections to the fuel-map values for optimum performance.

The ThunderMax AutoTune module adds closed-loop operation to your ThunderMax EFI module.

The AutoTune kit consists of two wide-band (five-wire) oxygen sensors and a small module that interprets and converts data from the sensors, which is then fed electronically through the J1850 serial bus wiring through the data port plug found on all Twin Cam motorcycles. This means that if you have sensor bungs in your exhaust pipes, the physical installation consists of simply screwing in the oxygen sensors, plugging them into the AutoTune module, then plugging the AutoTune module into the data-port plug, and you’re done-no wire cutting or splicing needed. Next, use SmartLink software to automatically convert your open-loop map to closed-loop format and download the map to your ThunderMax EFI module.

Here’s the modular AutoTune and ThunderMax EFI module cleanly installed under the seat. Everything is plug and play-no wire splicing necessary. The system can adjust up to 50 percent from the installed base map. Easy-to-follow instructions are included.

A closeup of the wide-band oxygen sensors. These are placed in your exhaust pipes, close to the head. Many exhaust-pipe manufacturers are delivering pipes ready for closed-loop EFI and will be supplying pipes with bungs in them.

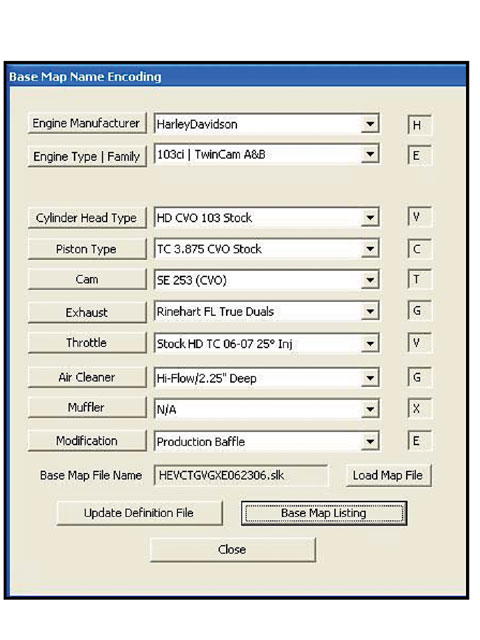

The base-map encoding table contains detailed information about your particular motor setup. With this information, the correct base map can be loaded into the ThunderMax module. This is one of the many diagnostic and parameter information tables contained in the SmartLink software.

Here at HOT BIKE, we strive to stay on top of the most innovative parts to hit the American V-twin industry, so we’re bringing you a new tech piece entitled “First Look.” With this series, we will search out the newest parts and get you the inside scoop on what they are and how they work. Then we will follow up in a future issue by actually installing the part(s), explaining the install process, and giving an evaluation.

Zipper’s Performance Products offers EFI kits and parts including throttle bodies, air cleaners, FI nitrous systems, and ECMs, as well as its new AutoTune module for any displacement and motor combination. The new ThunderMax AutoTune module adjusts AFR (air/fuel ratio) at all rpm and throttle positions through the feedback from two wide-band oxygen sensors placed in the exhaust pipes near the heads. The AutoTune Module works with the ThunderMax EFI controller to create a wide-band closed-loop EFI system that automatically adjusts fuel and ignition requirements due to performance upgrades such as pipes, an airbox, and cams. One of the best features is the ability to have closed-loop FI on your older Magneti-Mareli (MM) or Delphi system.

The ThunderMax EFI system is a joint development and distribution project between two industry leaders: Zipper’s Performance Products and ThunderHeart Performance. Zipper’s Performance Products is a leading developer and producer of engine kits and performance components for the H-D aftermarket industry. ThunderHeart Performance engineers, designs, and manufactures high-technology systems and components for the motorcycle industry. The company is committed to developing and improving the best engine-management and fuel-injection products in the industry, along with having a dedicated staff with outstanding customer support.

The Zipper’s ThunderMax EFI is a complete, stand-alone ECM for all ’02-present Delphi-based open- and closed-loop EFI Harleys. ThunderMax EFI simply replaces the factory O.E. system. The same technology is also available for all MM-based H-D ’97-’01 EFI-equipped motorcycles.

When design began on the ThunderMax EFI controller, the engineers had one goal in mind: to overcome the limitations of the stock system. The ThunderMax EFI eliminates the requirement of any add-on tuning products and was developed with complete versatility in mind. The system utilizes a very fast and powerful computer processor that allows a higher resolution of tuning points than any of the other popular add-ons. These points of adjustment are addressed during the creation of the base maps and are the key to unlocking a bike’s potential.

All processors use a look-up table to deliver the specified amount of fuel and spark timing for a given rpm/load situation. The ThunderMax is an Alpha-N-based system, meaning it relies on rpm and throttle position only; it does not use data from the MAP sensor. The V-Twin’s uneven firing pulses and common intake manifold can confuse the MAP sensor, and cause it to supply fuel and spark from the wrong area of the map (block), resulting in poor performance. For this type of system to work properly, it requires many more “blocks” on the look-up table. When designing the ECM, the company’s engineers covered the spectrum with a system that operates using 1,984 points. Simply put, regardless of throttle position and engine rpm, there is a block on the look-up table to address the engine’s needs in that situation. ThunderMax’s processor can keep up with the ever-changing demands, rewarding you with a smooth, efficient, and powerful engine.

While a base map is required depending on your engine setup, ThunderMax has an ever-growing library of base maps that includes many engine and exhaust combinations. These highly refined maps lower operating temperatures, eliminate exhaust popping between shifts and deceleration, and improve throttle response and performance. Maps were developed on a state-of-the-art eddy-current dyno using lab-type instrumentation. Should any adjustments be required, the easy-to-use SmartLink software supplied with the system allows adjustments of 20-percent air/fuel and 10 degrees of ignition timing to the supplied base map. Things such as adjustment, rpm limit, speedometer calibration, and others are simple click-and-enter affairs. Tuning can be performed “live” (engine running), along with live monitoring of 44 engine and system vitals viewed as on-screen gauges. Future engine upgrades require the simple installation of a new map-about a 2-minute process.

Magneti-Marelli designed Harley-Davidson’s first incarnation of fuel injection. That system was used on all the Evo EFI bikes, as well as the ’99-’01 Twin Cam touring bikes. Beginning in ’01, H-D switched to a Delphi-engineered FI system on the Softail, with all subsequent models equipped with EFI utilizing the Delphi system. Beginning with the ’06 Dyna and now present on all Harleys (including Sportsters) is a more sophisticated closed-loop feedback system that uses exhaust-gas oxygen sensors to make air/fuel changes on the fly.

Unfortunately, the early MM EFI had some shortcomings that affected performance, not only on stock bikes but particularly on modified motors. Some of the problems reported with the MM EFI were hard starting, erratic idle, and difficult tuning. For performance motors, the dual-plenum throttle body, with independent runners feeding each cylinder, was too small to pass the required air into the engine. Another major shortcoming was the flawed placement of the intake air-temperature (IAT) sensor within the throttle body. The ECM uses intake temperature to make adjustments to the fuel mixture. The problem with the sensor in the MM system is that the measured air temp is not an accurate reading of what the intake temp really is. When the air enters the venturi of the throttle body, it speeds up, changing its temperature. In addition, the throttle body sits right above the hot motor, compounding the problem of accurate air-temperature measurement. Another way the MM unit adjusts the fuel mixture is by the position of the throttle and rpm, a so-called Alpha-N system. A major advantage of throttle-based control is there’s no dependence on intake-manifold pressure-greatly benefiting motors with radical cams. For comparison, the Delphi EFI utilizes a MAP sensor in the manifold to determine the load on the motor and report back to the ECM for fuel changes. This method is called speed-density control, calculating airflow based on engine speed, manifold pressure, and temperature.