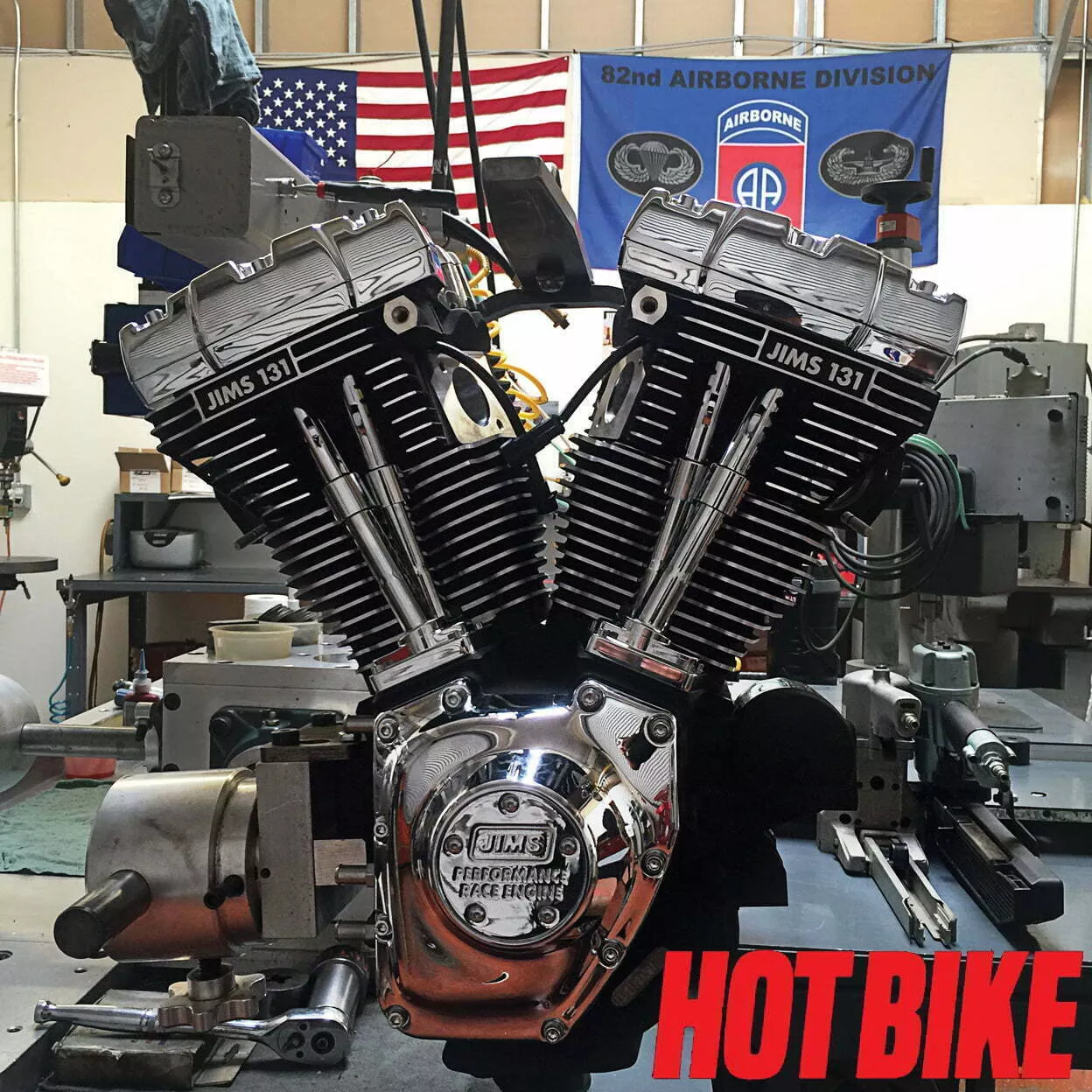

JIMS 131 Twin Cam Evo mount motor build

The new motor!

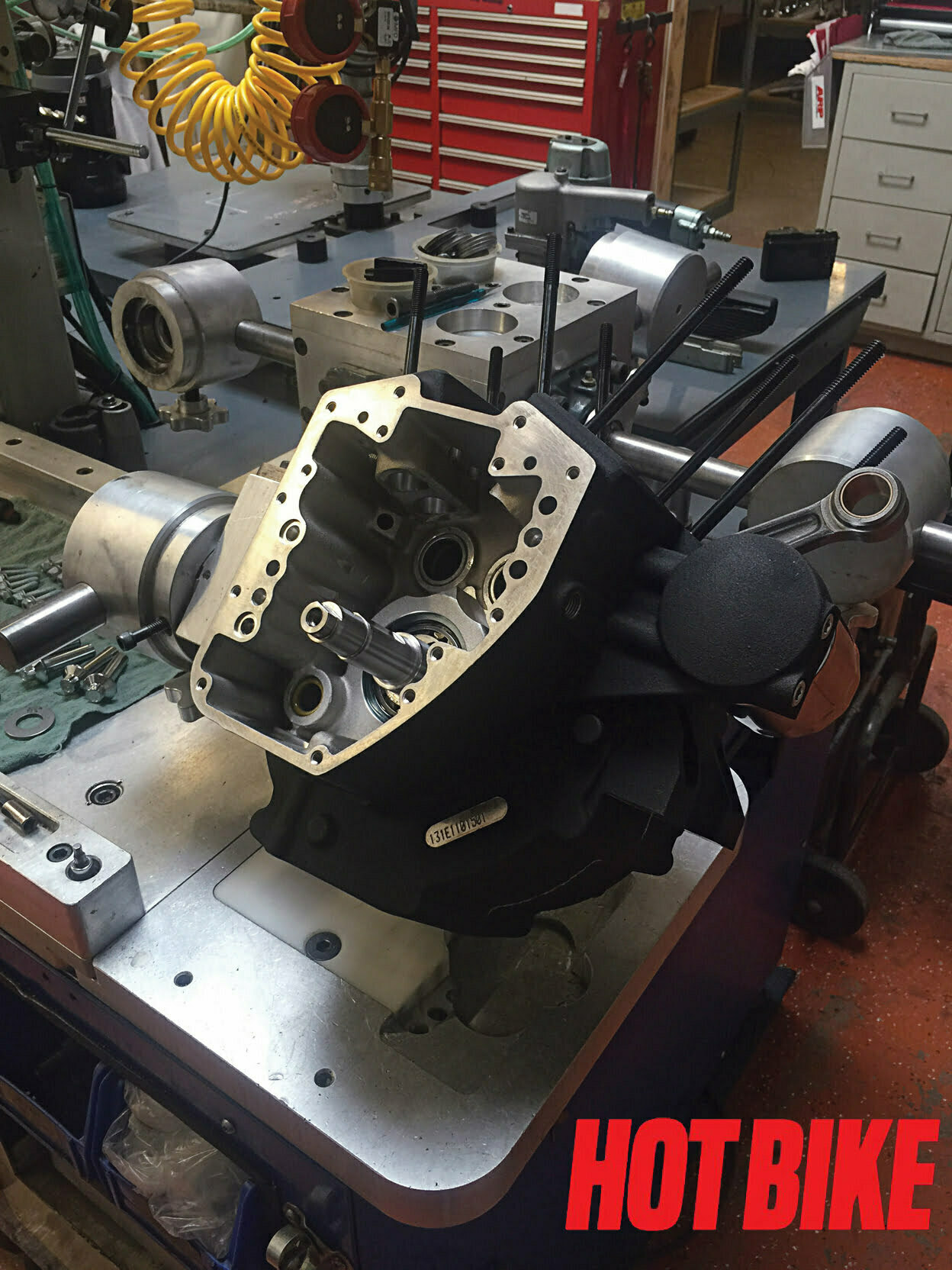

When we showed up, Greg already had the bottom end completed and the beefy ARP cylinder studs mounted up.

Here was a peek at the JIMS flywheel and rods installed in the engine case.

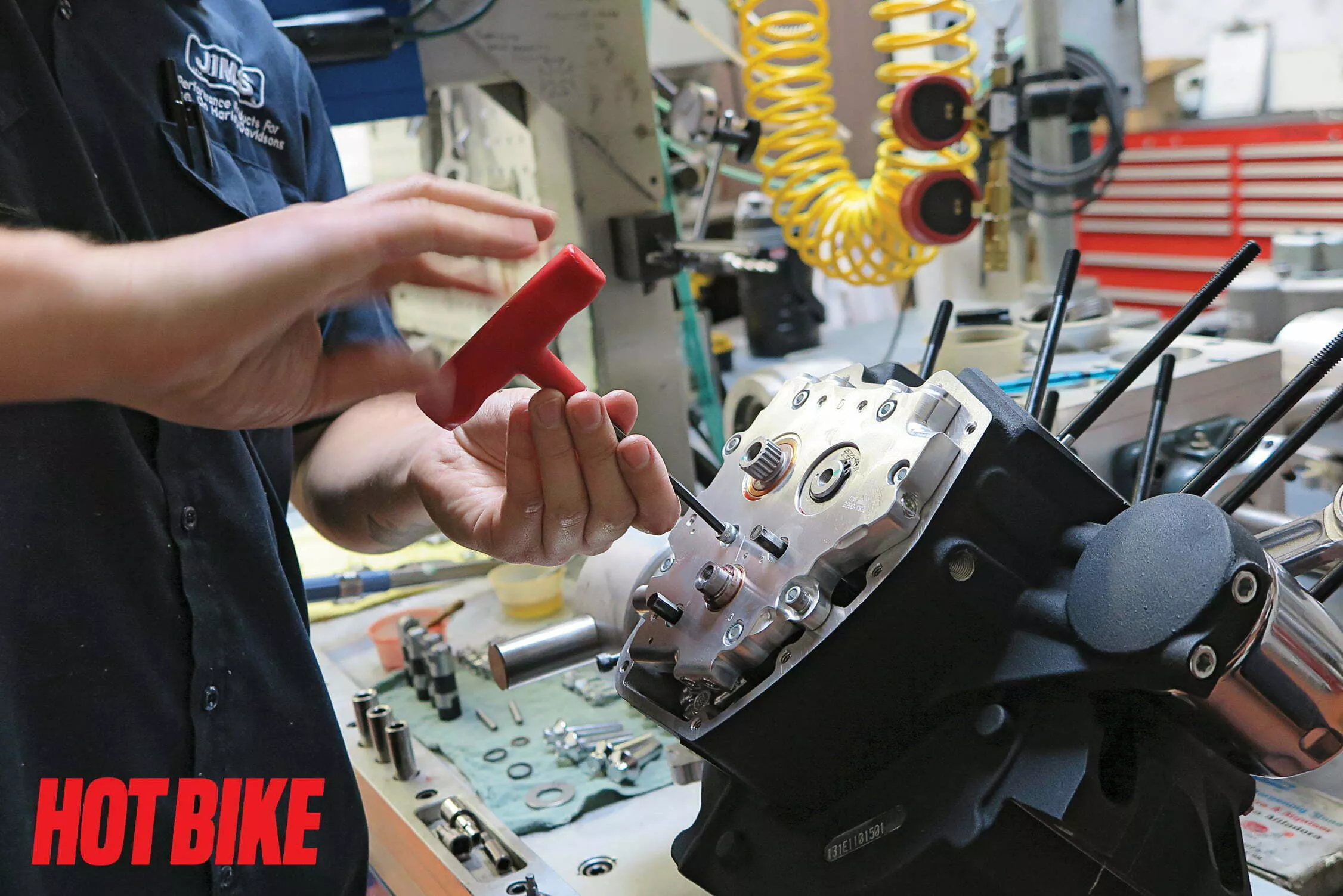

Greg installed the JIMS hi-flow oil pump, .635 cams, billet cam support plate…

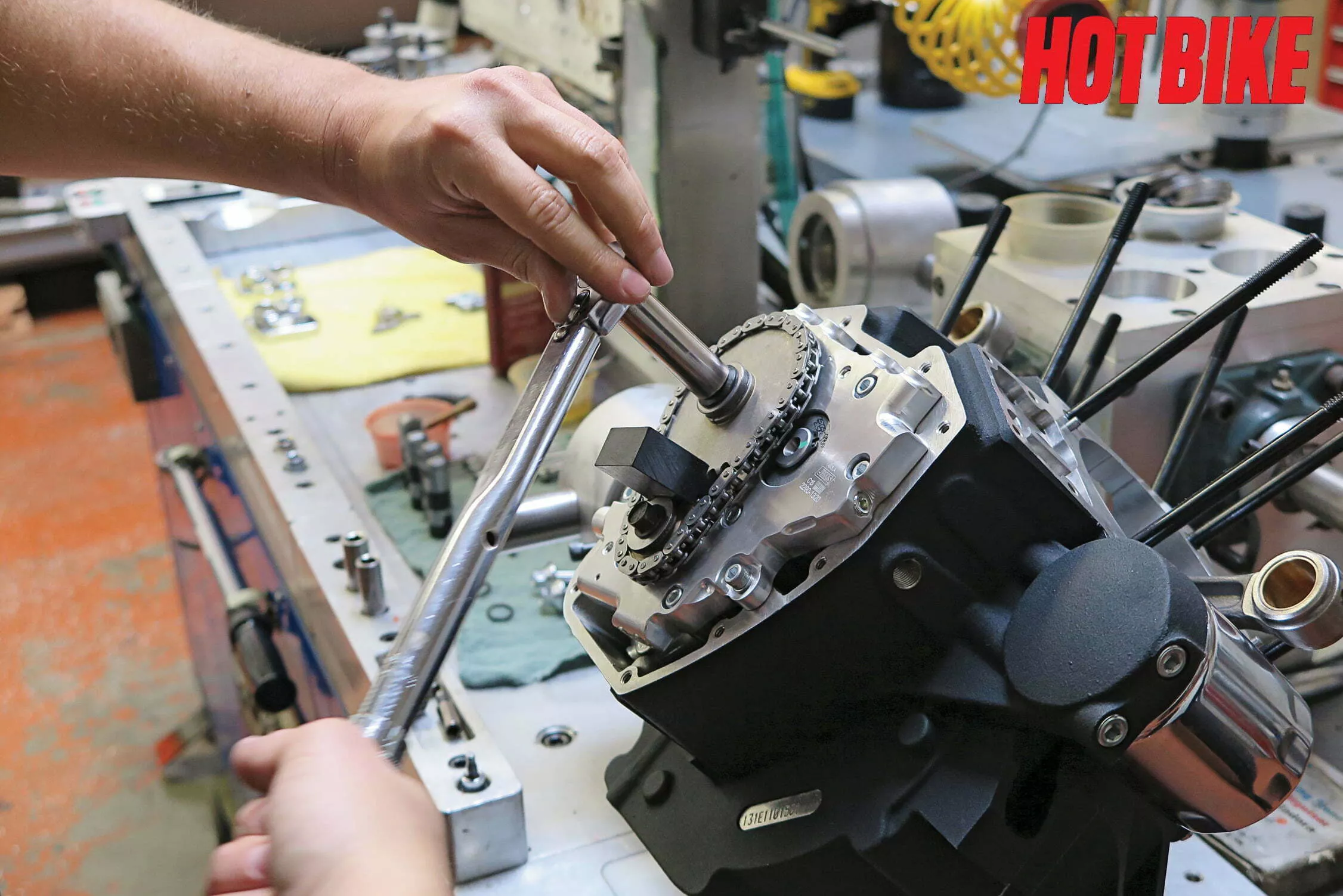

…and hydraulic tensioners before mounting the chain-drive system.

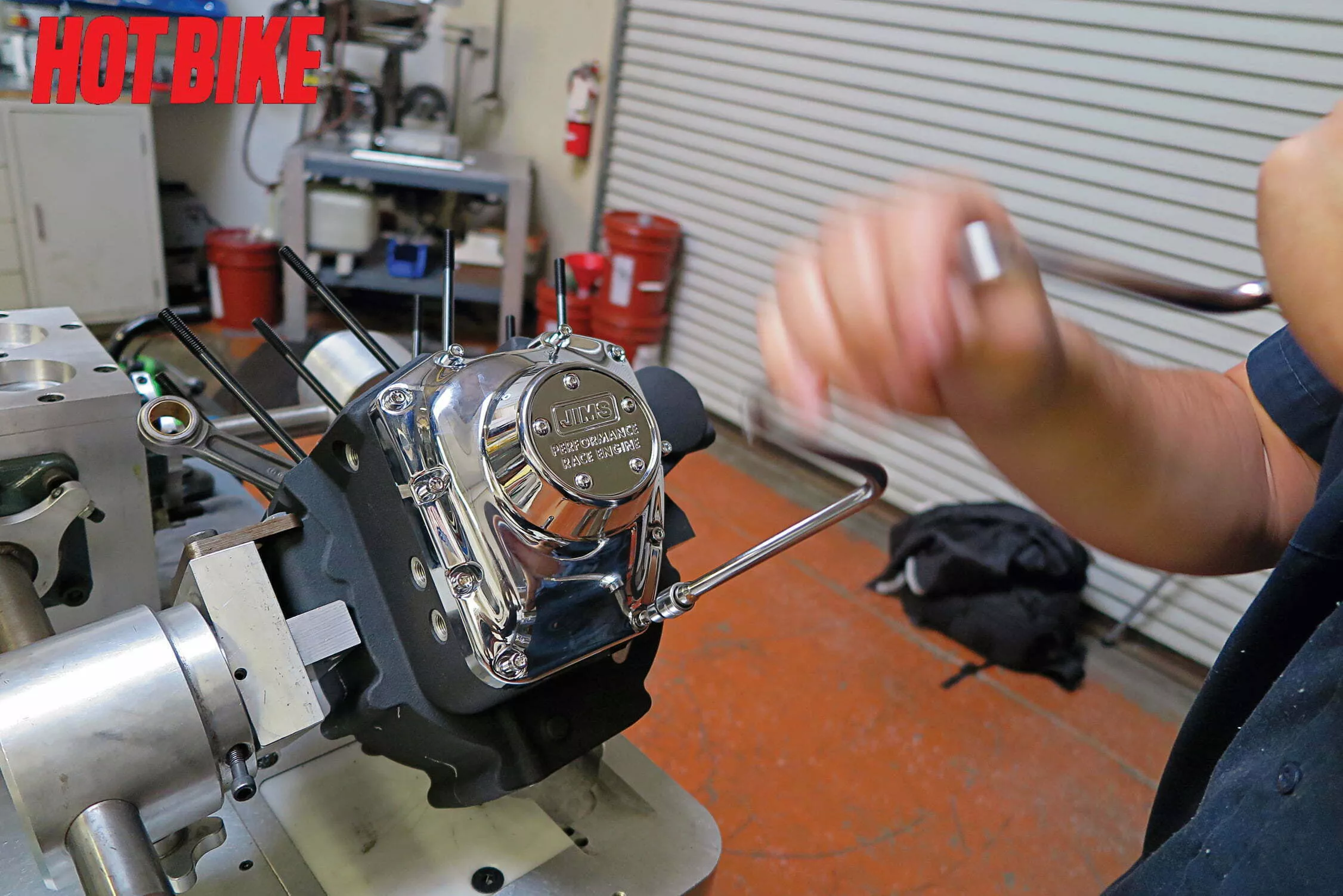

After all the bottom-end business was sorted, Greg installed the JIMS cam cover.

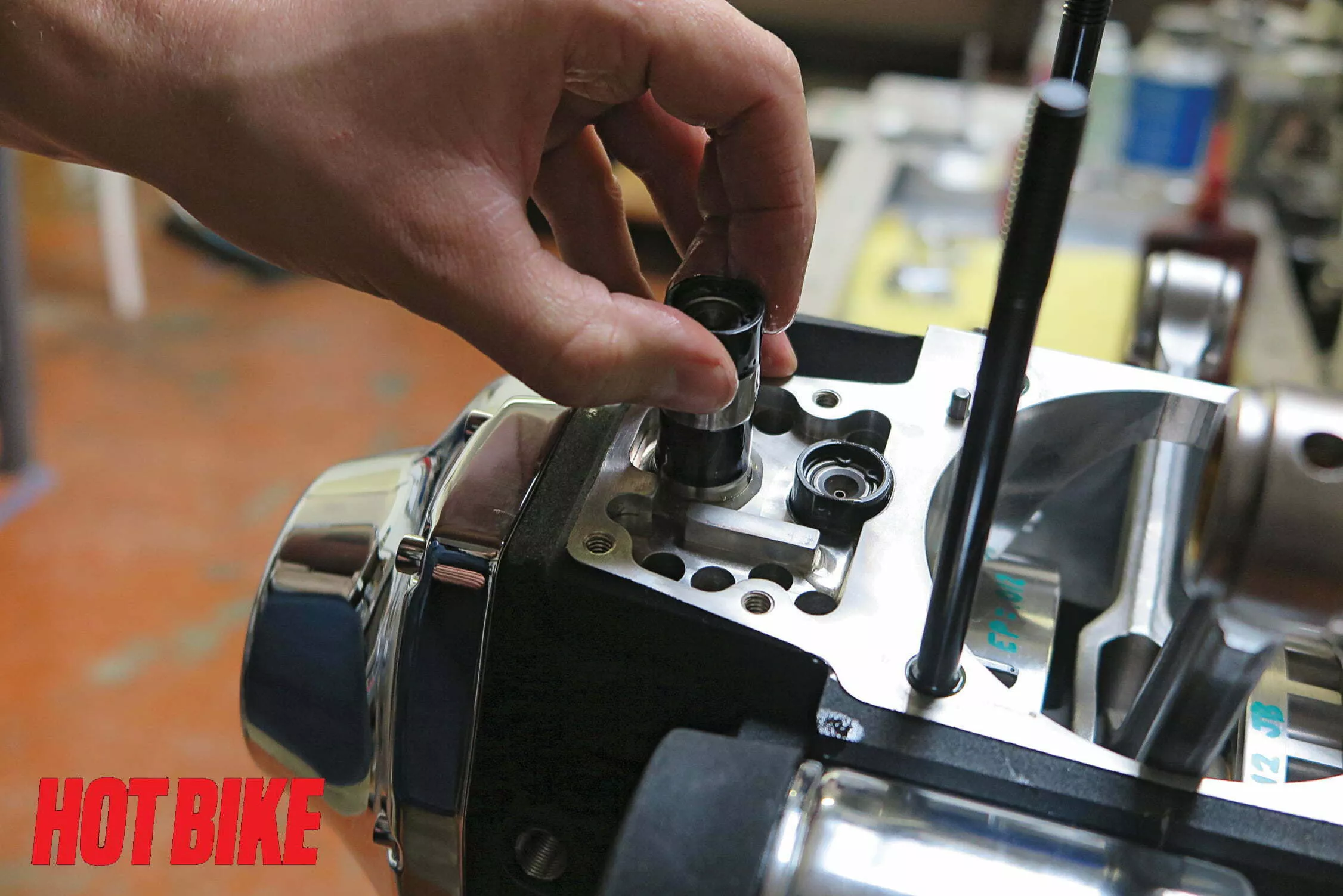

A set of JIMS renowned Powerglide II Tappets were installed

Some gleaming chrome JIMS tappet blocks were also bolted to the engine.

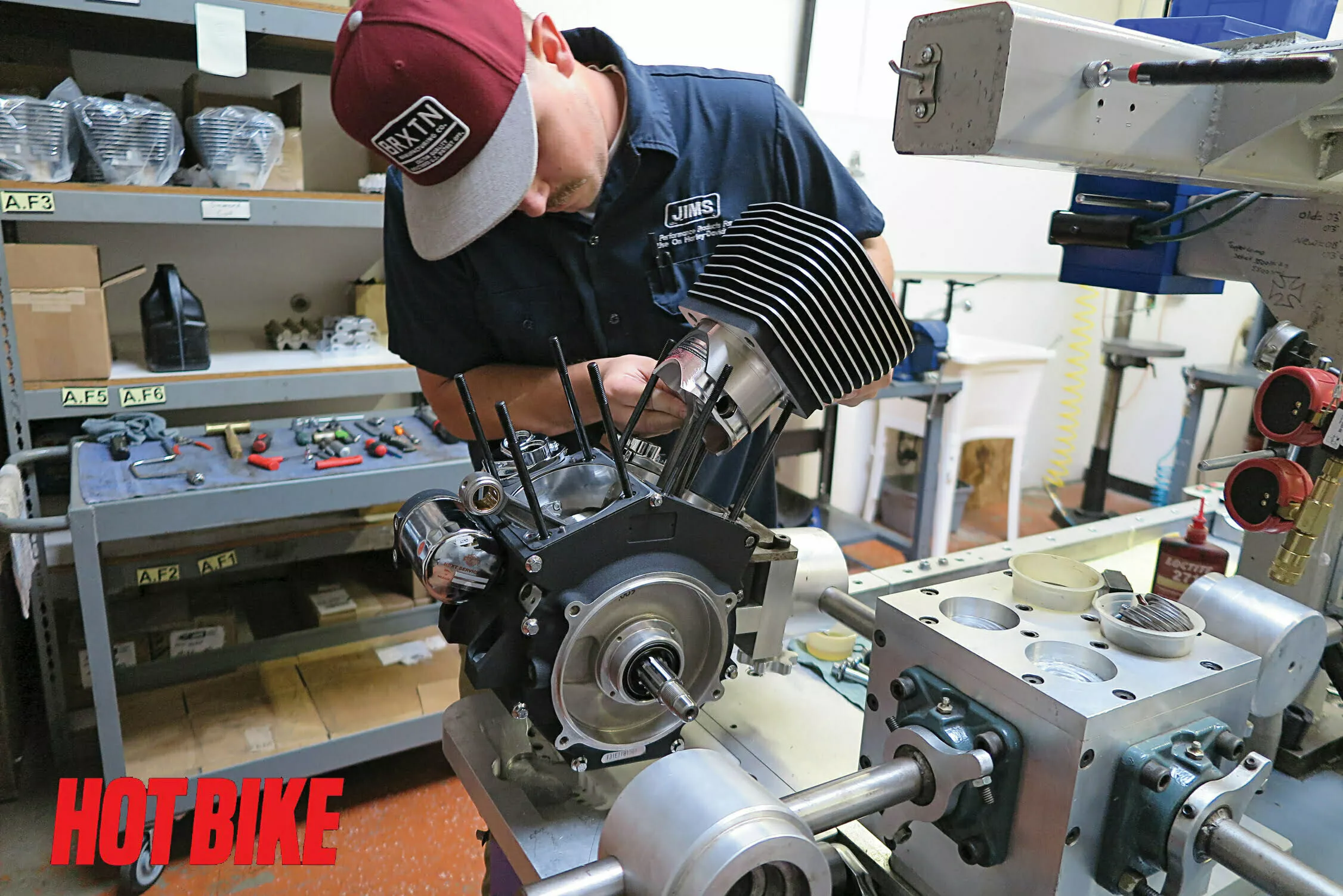

Greg installed the rear JIMS forged piston and carefully slid the cylinder over it.

The front piston and cylinder also followed suit.

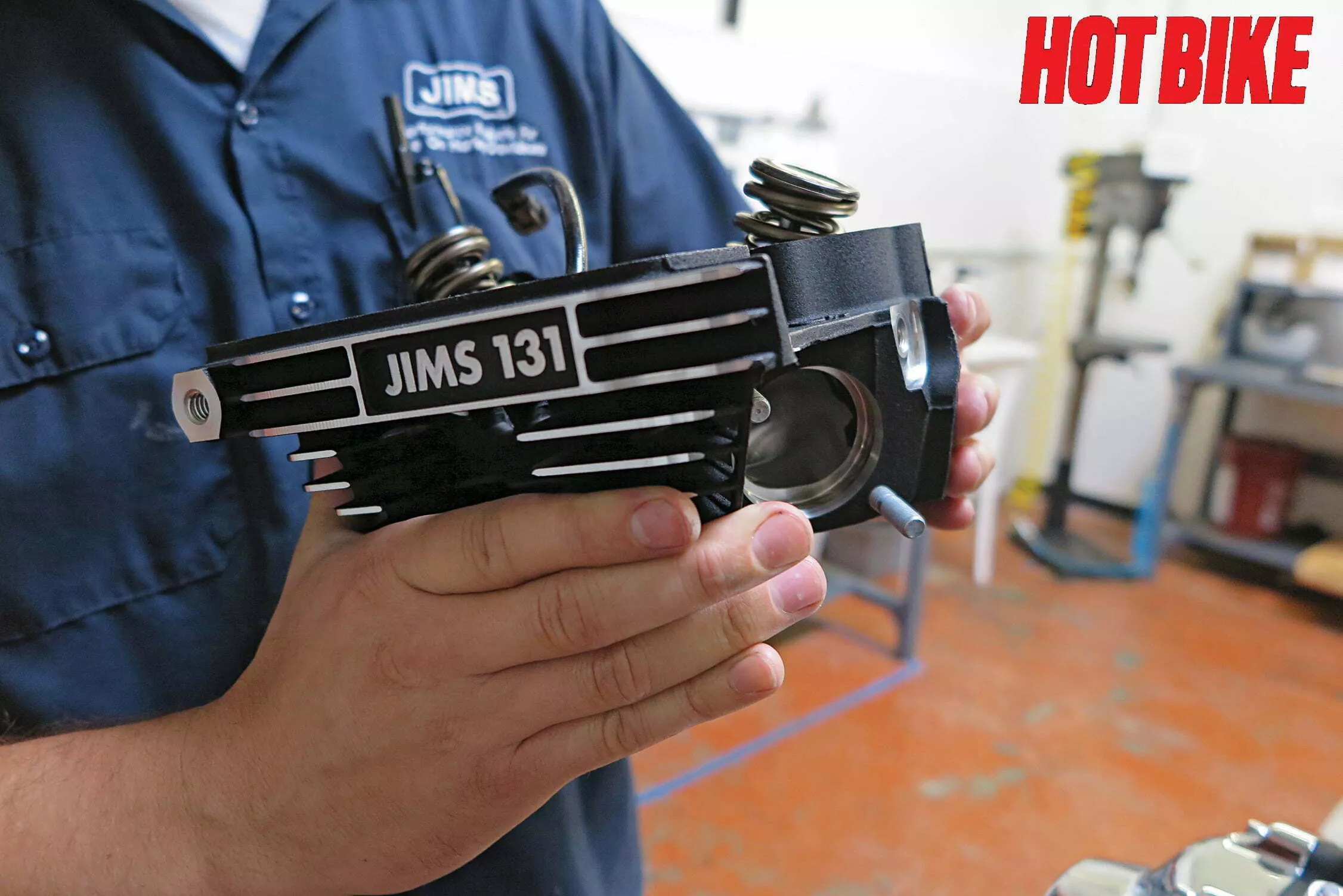

A set of CNC-ported 131 JIMS heads filled with JIMS roller rockers and Screamin’ Eagle valves and valve springs where then fitted to the engine.

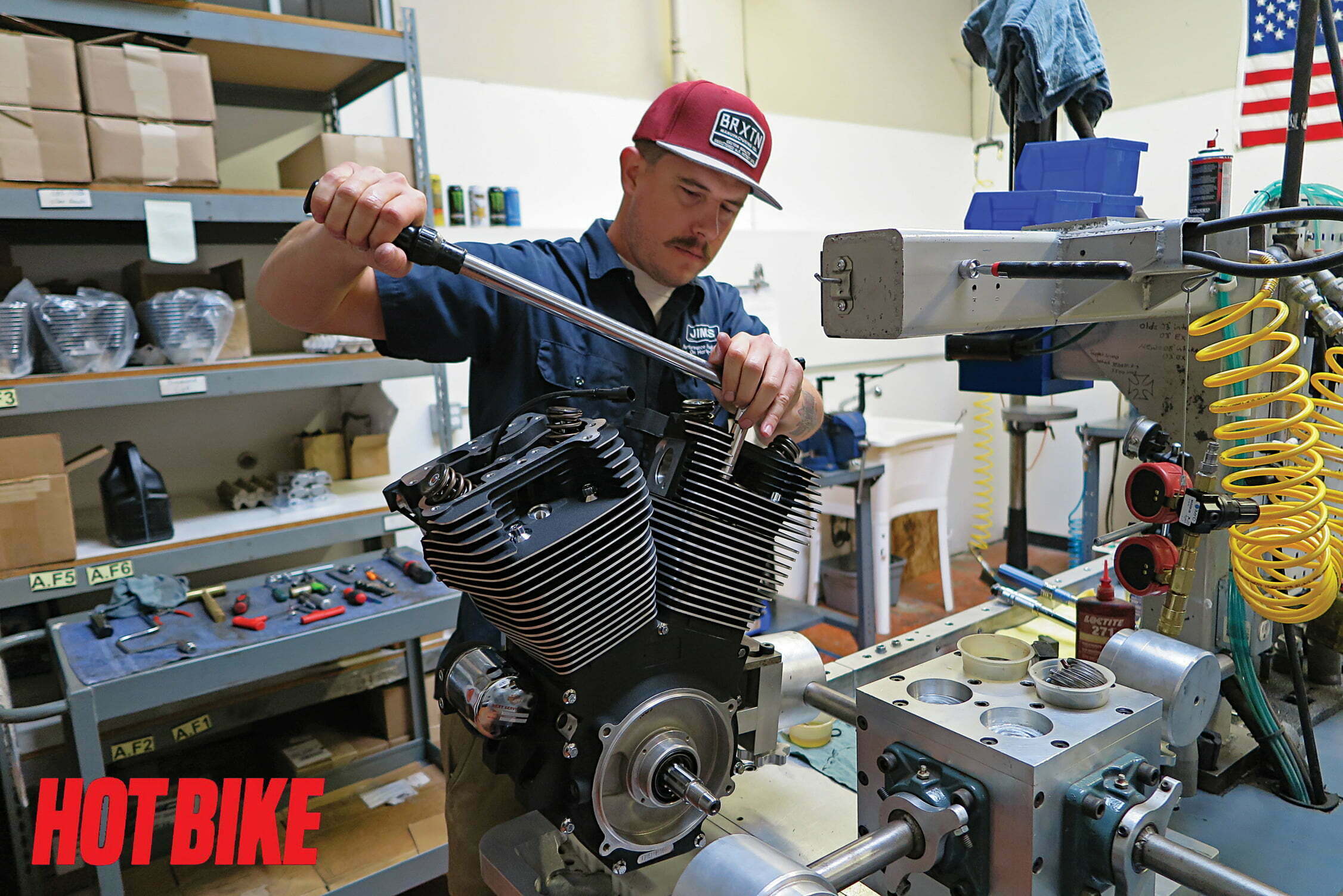

Greg torqued the top-end components up to JIMS stringent specifications.

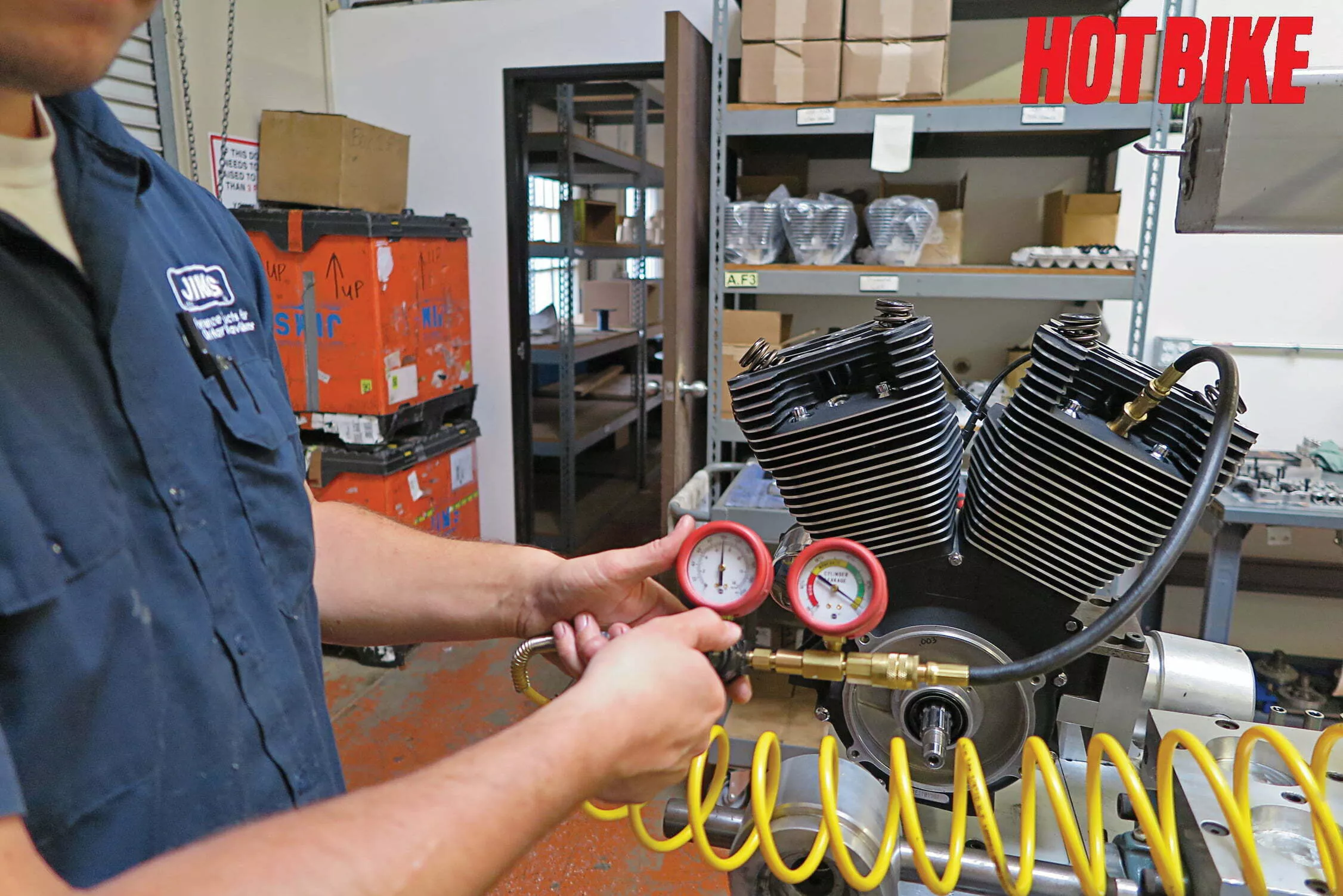

A leak-down test proved that this motor was indeed up to snuff so far.

A set of Screamin’ Eagle adjustable pushrods were then installed.

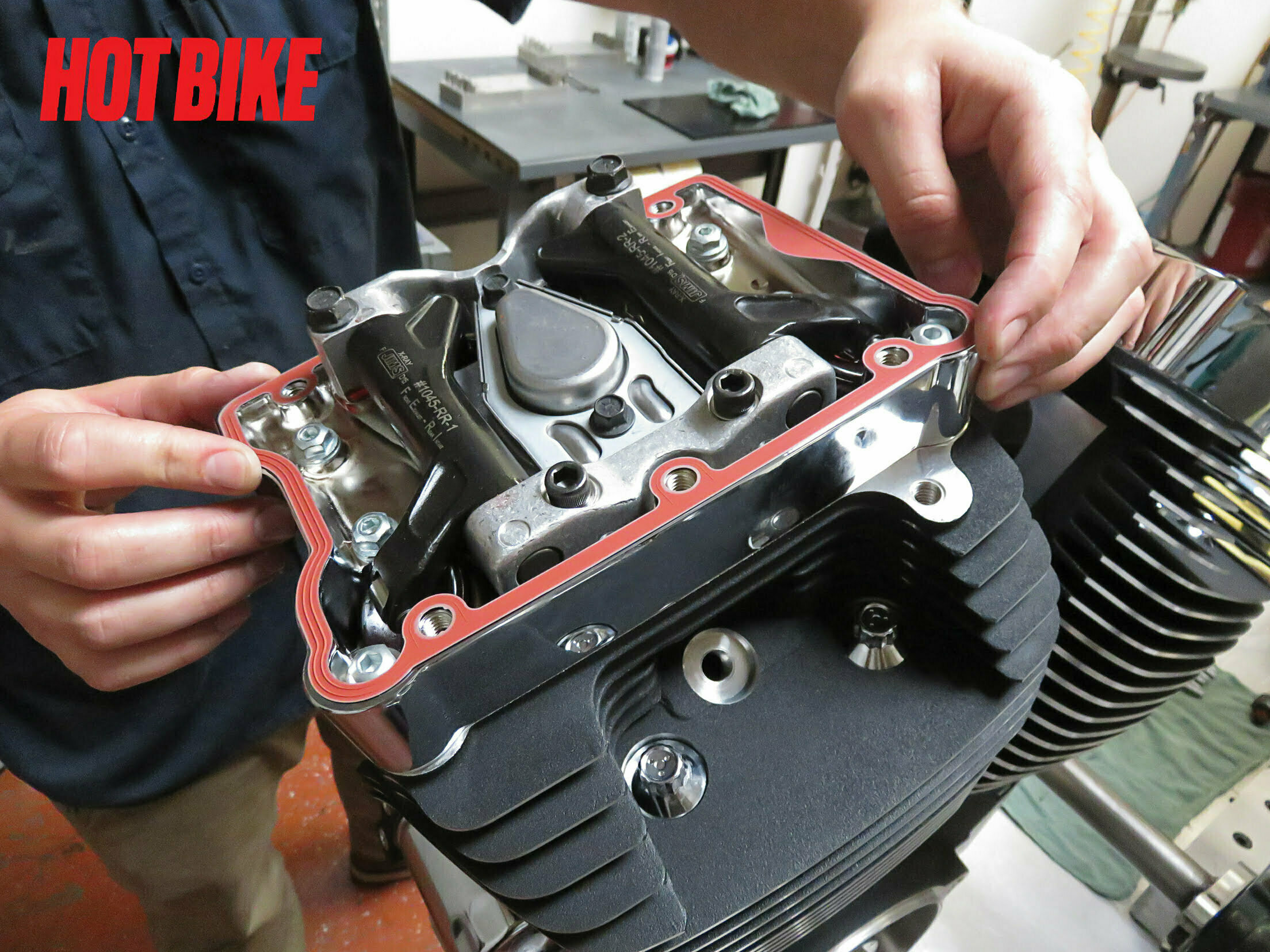

Greg installed a set of Gates gaskets for the lower rocker box cover.

The lower section of the two-piece Twin Cam rocker box covers was fitted.

Once all four-rocker box tops were bolted up, Greg torqued them to spec.

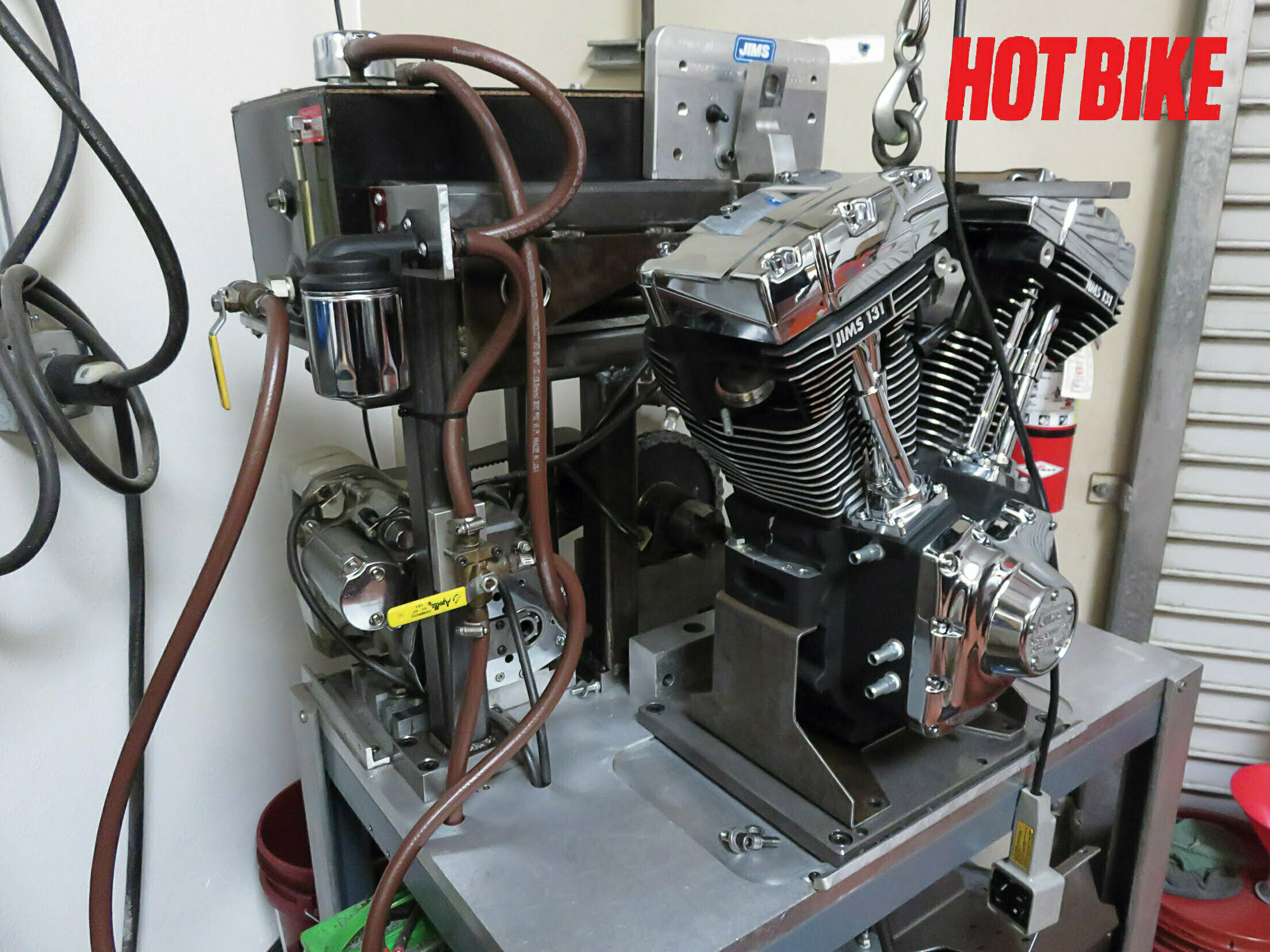

Now that the mass of parts were a complete engine, it was run briefly on JIMS “Dry” engine stand to check for any issues, which it of course had none.

The last detail of any JIMS race series engines is this name plaque, which no engine receives until it passes all quality control and performance

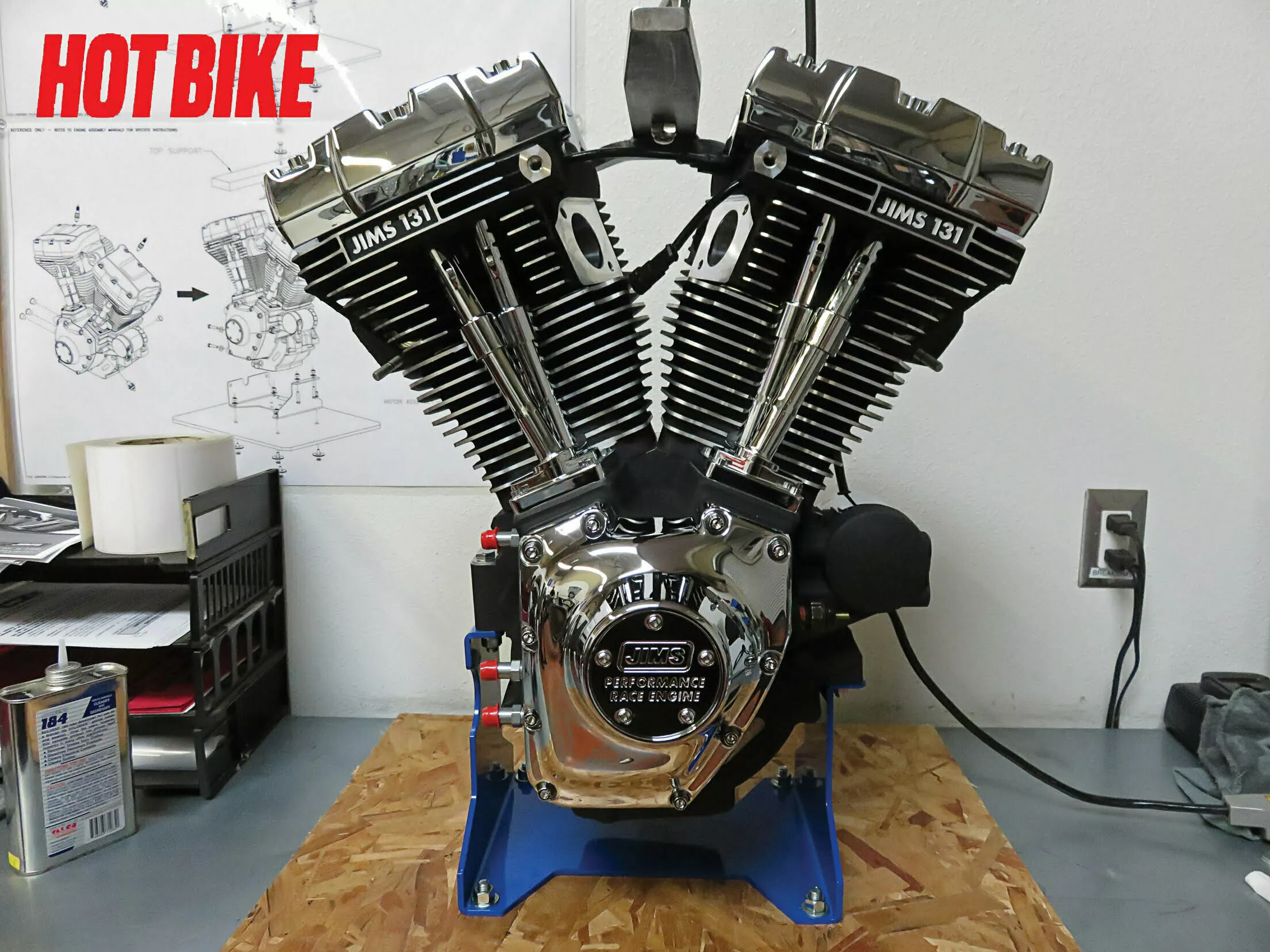

And here it is: a massive JIMS motor for our next project FXR.

Say you have an old and tired bike on your hands but you just don’t want to let it go. In our case, we have a 1993 FXR and want maximum horsepower without a ton of hassle. Well, with this particular JIMS 131 we can and will have both!

See, this motor is a Twin Cam design, but it fits in an earlier Evolution-style chassis. This easily updates any sort of older bike to the newest in mega horsepower powerplants with the proven performance and reliability of a Twin Cam design.

Like all JIMS engines, these are ground-up builds made one by one to order. And the 131 is chock-full of the best components, including CNC-ported heads, oil-pressurized tappets, 10.5:1 compression, a 4-1/2-inch stroke, and a bore of 4-5/16 inches. The 131ci fire-breather also has a proprietary JIMS press-fit flywheel with chromoly rods, forged pistons, and possesses a whopping 130 hp and 135 pound-feet of torque out of the crate. We were invited by the man Jim Thiessen, his right-hand man Paul Platts, and the gang at JIMS to come to their HQ and watch our 131 motor come together before our very eyes with the skilled labor of Jim’s son Greg Thiessen. Here’s how it went down.

Source

JIMS USA

jimsusa.com