TIG Welding 101 For Motorcycles

- The finished product welded out, following these fundamentals.

Tyler Sawicki

For as long as I can remember, I’ve been building exhausts for just about any vehicle I could get my hands on. I have always felt that there are few things in life more satisfying than hearing a motor roar to life through an exhaust system that you’ve spent countless hours planning and building. And that is why I do it!

- A well-prepared TIG setup is the key to success when welding.

Tyler Sawicki

In this first article (of many) I will break down techniques and skills that will hopefully make your next fabrication project a little more refined when you press down that pedal and put your torch to metal. For those of you who are beginners, we are going to start from the ground floor of precision TIG work. We’ll be looking at machine setup, torch options, and gas flow. The machine basics are some of the most important and often overlooked keys to laying some high-quality work. You don’t need a super-expensive rig or the latest and greatest accessories to do high-quality work. Just knowing the fundamentals will help up your welding game.

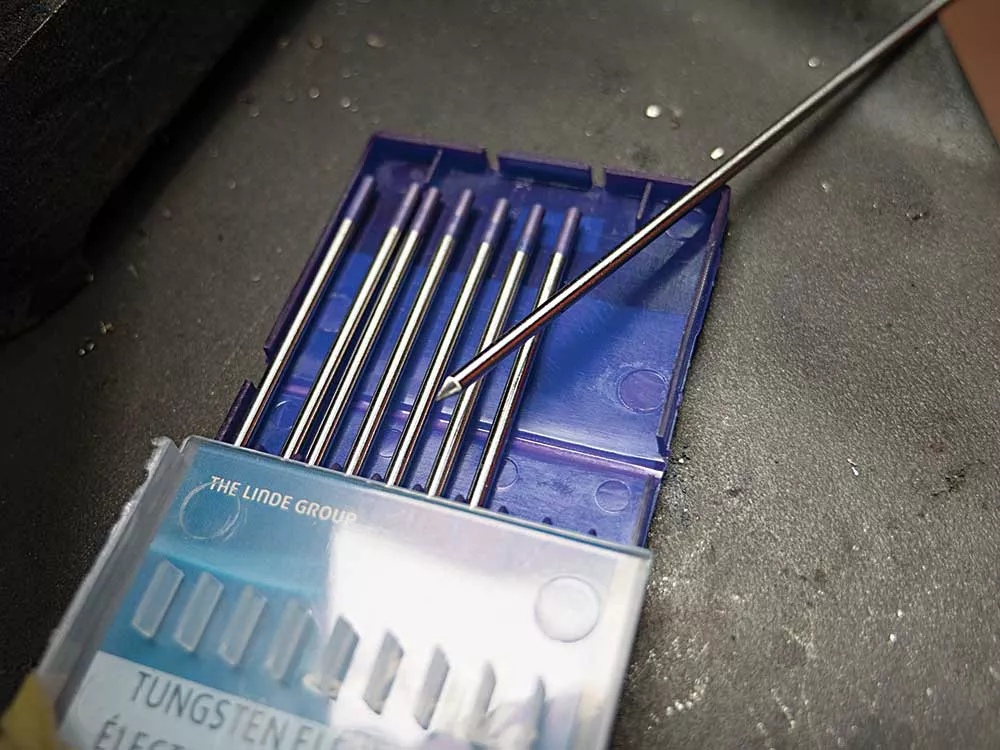

- Non-radioactive hybrid electrodes: They have excellent arc control, last a long time, and perform phenomenally on many materials from mild steel to titanium.

Tyler Sawicki

Start at the arc! A consistent, predictable, well-focused arc is a game changer. There are a slew of modern tungsten electrodes available in today’s market. One of the biggest favors you can do yourself to improve the quality of your welding is try a “hybrid” electrode. They work well for a variety of materials, sharpen nicely, last a long time, and aren’t radioactive so you won’t glow in the dark.

- Welding cups can be a game changer. From left to right: Standard #7 cup, great for production work or mild steel welding. The modern #12 cup puts out a tremendous amount of coverage while not using that much more gas, so it is my go-to on most stainless work. The massive high-coverage cups are best reserved for titanium and other special applications, as they use a large amount of gas but can shield just about anything.

Tyler Sawicki

Now that you know what tungsten to grab from your local welding store, what do you do with it? Sharpen it to a point! Whatever shape you sharpen your electrode into, the arc leaving it will resemble that shape. So sharpen it to a point! You’ll get well-focused, reliable arcs. Around a 25- to 40-degree taper on your tungsten is suggested. Remember when sharpening your tungsten, grind it the same direction that current will travel out of the electrode. This will make that arc even more predictable. Read on, my friends, and I hope these words and photos will aid you in being the welder you always wanted to be!

- Welding control panels can make your head spin. The face of my Miller Aerowave has more control than almost anyone needs, so try to keep it simple and focus on the fundamentals.

Tyler Sawicki

- By following these basic fundamentals, you can make your work look truly professional and be very proud to show it off.

Tyler Sawicki