Wheel Tech: Big Numbers

- Here is the lowly 19-inch front wheel for our FXE in need of some growth.

Words and Photos: Jeff Leighton

- We chucked up our die grinder, cut the spokes, and cleaned up the hub a bit.

Words and Photos: Jeff Leighton

- The parts pile was laid out and ready to be built.

Words and Photos: Jeff Leighton

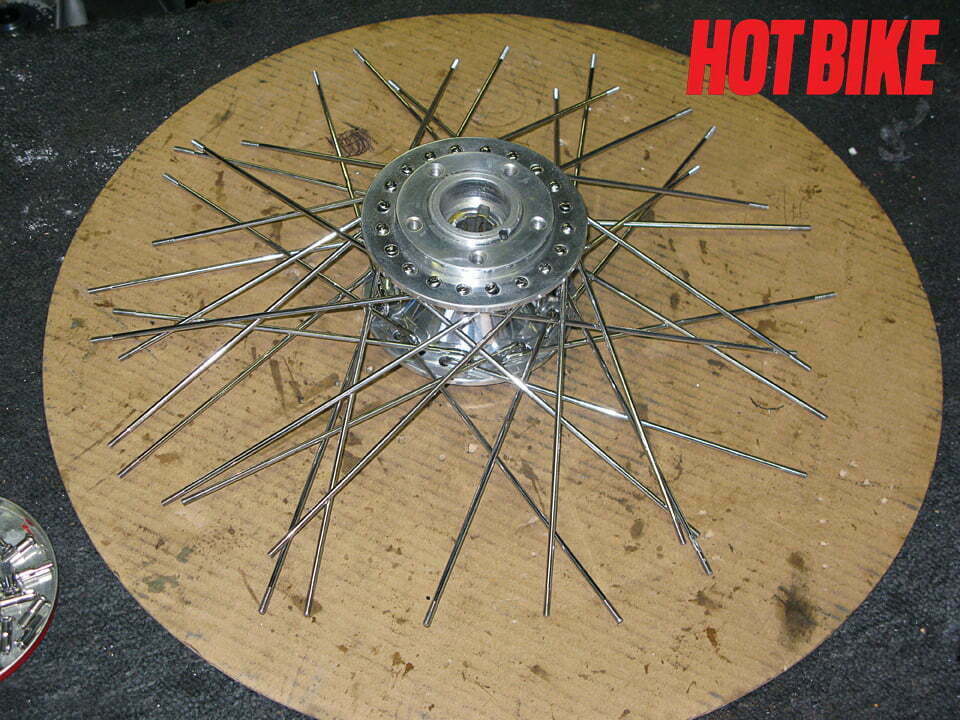

- All of the spokes were installed into the hub and four-crossed before the rim was laid over them to check for proper fit.

Words and Photos: Jeff Leighton

- Once everything checked out okay, the nipples were screwed onto the spokes a few turns each.

Words and Photos: Jeff Leighton

- The nipples were then further screwed onto the spokes with an electric drill.

Words and Photos: Jeff Leighton

- The bearing races were pressed into the hub and the surface greased.

Words and Photos: Jeff Leighton

- Fresh grease was also pumped into the new Timken bearings.

Words and Photos: Jeff Leighton

- Adam installed the bearings, got the wheel on the truing stand, and started adding tension to the spokes.

Words and Photos: Jeff Leighton

- When the wheel was near completion, Adam measured the trueness of the wheel both vertically and laterally.

Words and Photos: Jeff Leighton

- Once the wheel was arrow-straight and properly tensioned, Adam installed a new Avon Speedmaster tire.

Words and Photos: Jeff Leighton

- The wheel was then digitally checked for proper balance.

Words and Photos: Jeff Leighton

- A wheel weight was installed to correct the wheel’s minor imbalance.

Words and Photos: Jeff Leighton

- The new larger-circumference wheel was finally mounted on the bike and we were ready to ride!

Words and Photos: Jeff Leighton

When I got this project ’79 FXE Harley, it was dripping with cheesy ’80s ride-to-live chrome covers and a ton of other crap destined for the dumpster. After we had stripped off most of the lameness, we decided the old 19-inch front wheel needed to be replaced with a 21-incher neatly wrapped in an Avon Speedmaster.

Since this bike is a commuter, we decided retaining the dual-disc setup was probably a good thing. Instead of buying a new wheel off the shelf, we were going to build a wheel with the stock 35mm hub the bike came with. After asking our pals at Wheel Works for some advise on spoke sizes and the best rim to use, one of the techs, Adam, suggested it would be better and much faster if we just bring the hub in and let them work their magic.

So the very next day, camera in hand, we trucked on over to see just how the pros build a wheel. Once there, we chose to go with a set of stainless-steel spokes, stainless nipples due to their anti-corrosion properties, and a chromed-steel no-name 21×1.85 rim because it matched the rear H-D wheel to a T.

It took Wheel Works a fraction of the time it would have taken us to lace up the wheel, put new bearings in the hub, and get it trued and tensioned correctly. Even though we like to work on our bikes ourselves, it is good to know that at 70 mph this wheel is not going to send us to an early grave. Thanks, Wheel Works!

Follow Hot Bike‘s other build projects here.

Sources:

Avon Tyres

(877) 890-8473

Wheel Works

(714) 530-6681